Energy bus type battery equalizing circuit

A battery balancing and bus-type technology, applied in the direction of battery circuit devices, circuit devices, collectors, etc., can solve the problems of reducing the service life of the battery system, reducing solar power generation, low reliability, etc., to achieve high battery performance optimization, no Controllable effect of heat consumption and balanced current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0037] An embodiment of an energy bus type battery balancing circuit of the present invention is as follows:

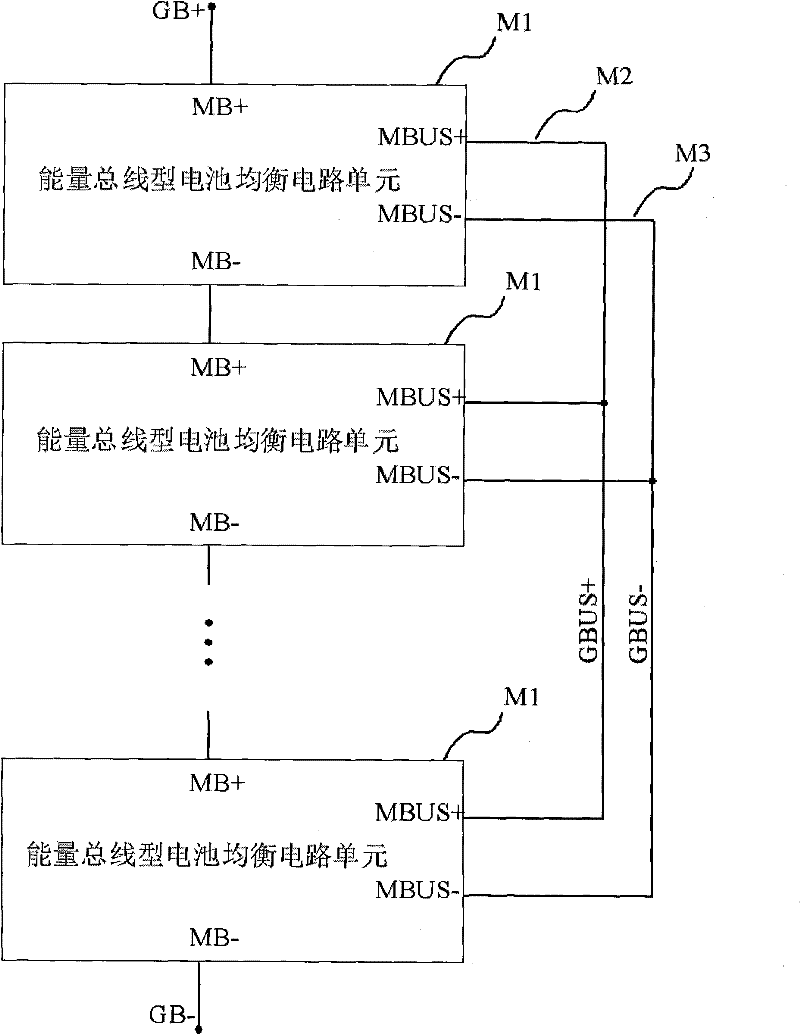

[0038] see figure 1 , is a battery system composition diagram of several energy bus type battery equalization circuit units of an energy bus type battery equalization circuit of the present invention. Such a composition is called a battery system, which is composed of an energy bus type battery equalization circuit unit M1, an energy bus positive pole M2, and an energy bus negative pole M3. Each energy bus-type battery equalization circuit unit M1 is connected in series with its battery positive pole MB+ and battery negative pole MB- end-to-end, and the total voltage obtained is the voltage of the battery system. The total voltage is equal to the sum of the battery voltages of each energy bus type battery balancing circuit unit M1. At the same time, the positive electrode MBUS+ and the negative electrode MBUS- of the energy bus of each energy bus type battery balanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com