Power factor correction method for LED (light-emitting diode) lighting

A power factor correction and LED lighting technology, which is applied in lighting devices, output power conversion devices, light sources, etc., can solve problems such as lack of independent research and development capabilities, blind investment, and lack of industry standards, so as to alleviate heat dissipation problems and improve LED life. , the effect of high conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

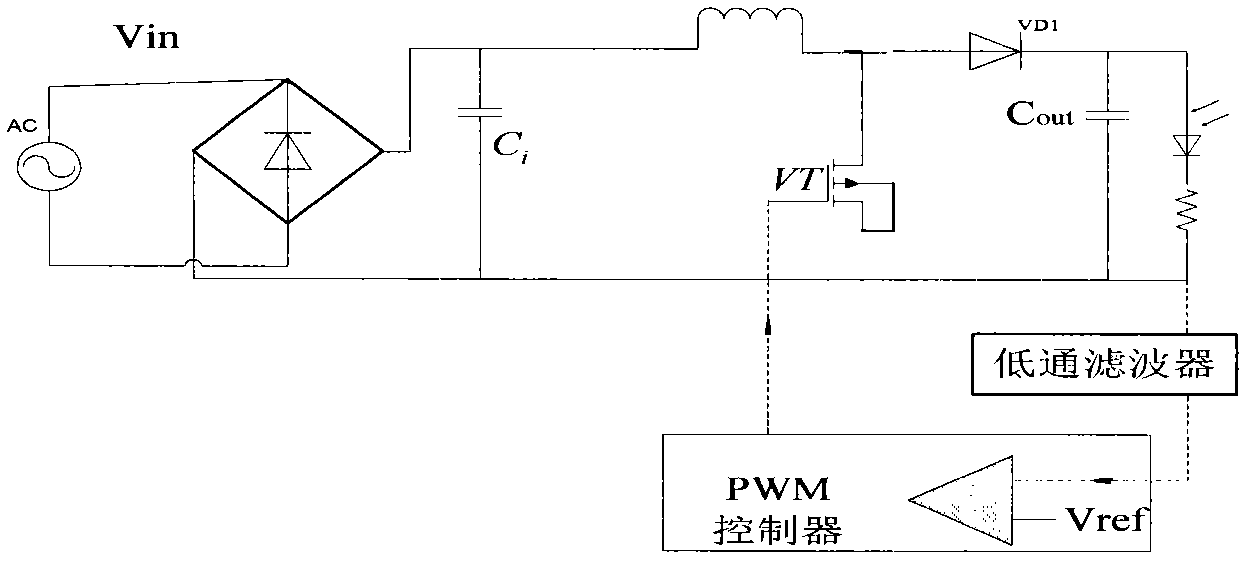

[0027] Power Factor Correction (PFC) refers to the relationship between effective power and total power consumption (apparent power), that is, the ratio of effective power divided by total power consumption (apparent power). Basically, the power factor can measure the degree to which electricity is effectively utilized. When the value of the power factor is larger, it means that the power utilization rate is higher.

[0028] Currently, the active power factor correction technology used in the field of LED lighting adopts two schemes of working in a discontinuous conduction mode (Discontinuous Conduction Mode, DCM) or a critical conduction mode (Critical Mode, CRM).

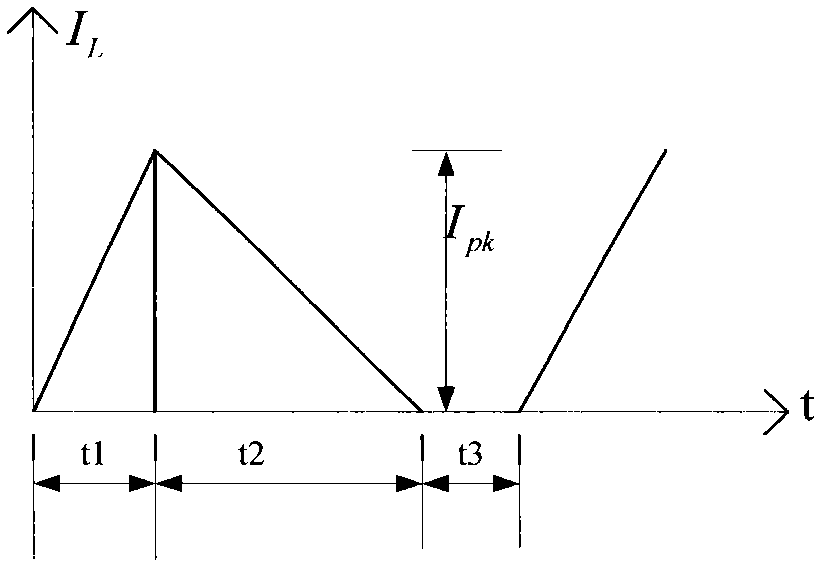

[0029] The working frequency of the DCM control mode is constant, and the current passing through the inductor is a high-frequency triangular wave. When the inductor current drops to zero, the switch VT is not turned on immediately, resulting in a dead zone where the inductor current is zero and does not flow conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com