Hydrophilic propolis powder capsule composition and production method thereof

A production method and technology of propolis powder, which are applied in the field of hydrophilic propolis powder capsule composition and its production, can solve the problems of loose products, difficulty in removing auxiliary agents, complicated preparation methods, etc., achieve cancer cell growth inhibition, and simple ingredients , The effect of cancer cell growth is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

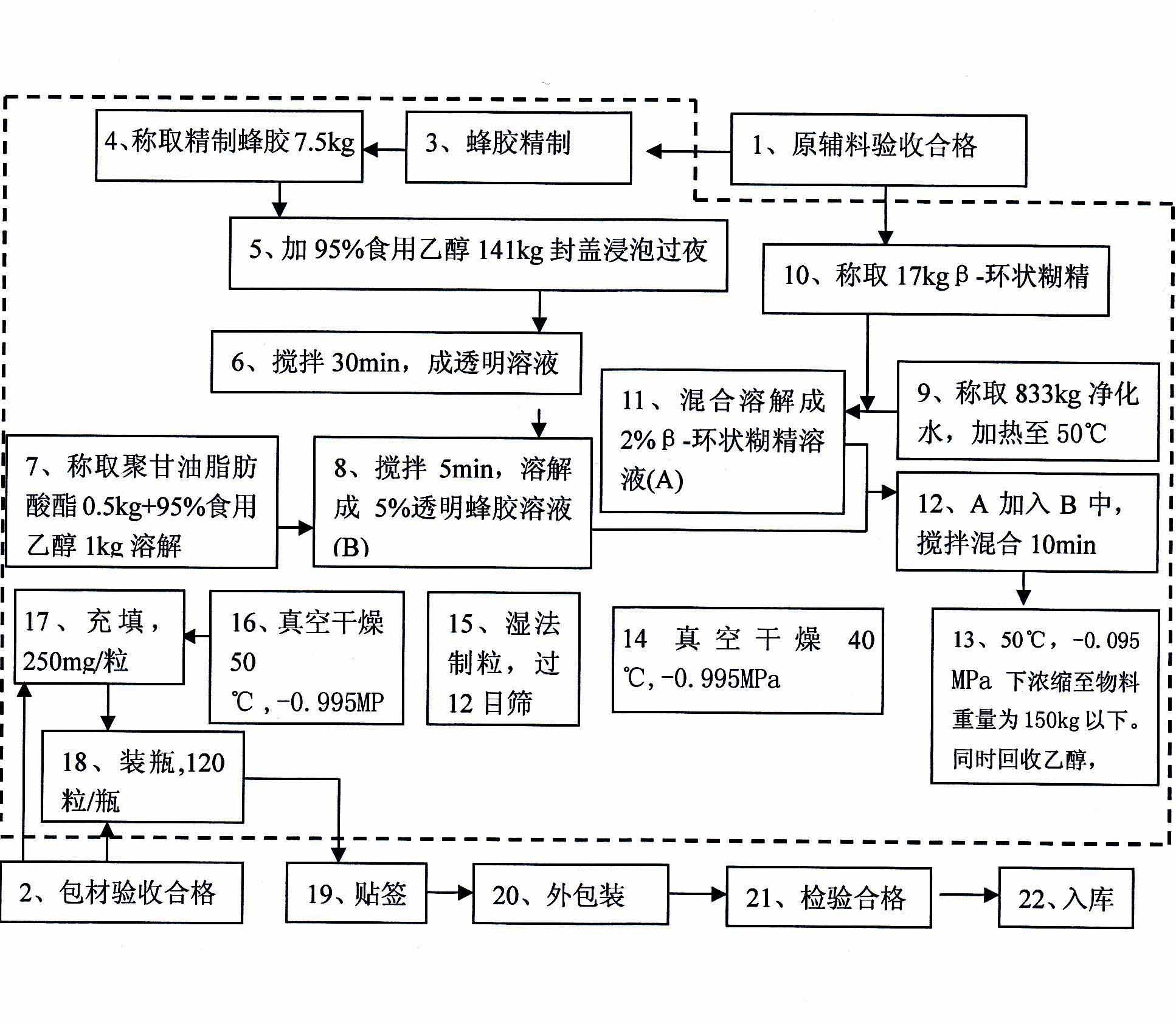

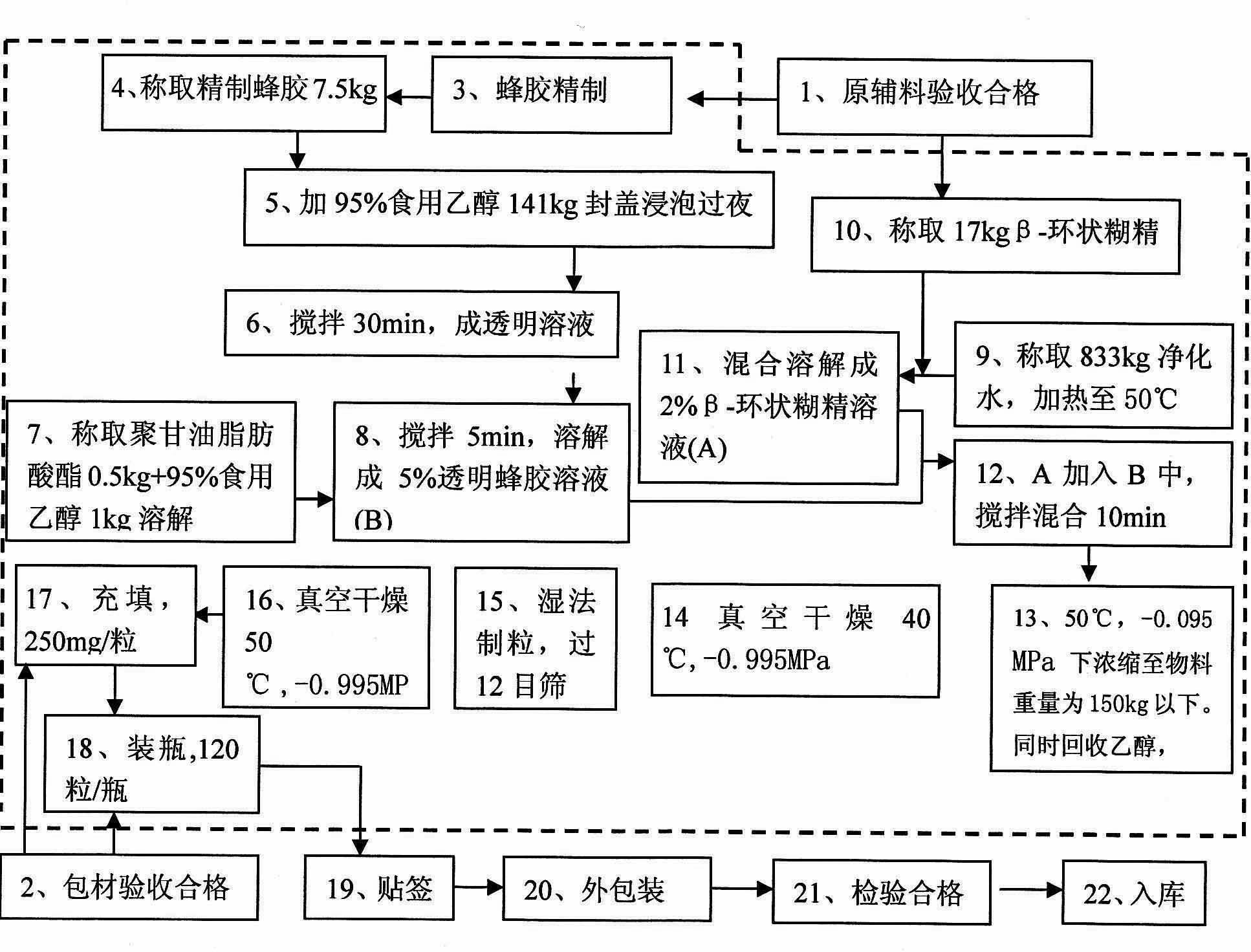

[0045] see figure 1 , the hydrophilic propolis powder capsule composition in the present embodiment comprises propolis, cyclodextrin and polyglycerol fatty acid ester, wherein, cyclodextrin is preferably β-cyclodextrin or hydroxypropyl-β-cyclodextrin dextrin.

[0046] The parts by weight of propolis in the present embodiment are 30 parts, the parts by weight of cyclodextrin are 68 parts, and the parts by weight of polyglycerol fatty acid ester are 2 parts, for example get propolis 7.5kg, cyclodextrin 17kg and 0.5kg of polyglyceryl fatty acid ester, or 30g of propolis, 68g of cyclodextrin and 2g of polyglyceryl fatty acid ester, etc. In the hydrophilic propolis powder capsule composition of the present invention, the parts by weight of propolis are usually 1-40 parts, for example, the parts by weight of this propolis can be 1 part, 2 parts, 3 parts, 4 parts, 5 parts, 6, 7, 8, 9, 10, 11, 12, 13, 14, 15, 16, 17, 18, 19, 20, 21, 22 , 23, 24, 25, 25.5, 26, 26.5, 27, 27.5, 28, 28...

Embodiment 2- Embodiment 31

[0063] Table 1 is the relevant parameter table of embodiment 2-embodiment 6, and table 2 is the relevant parameter table of embodiment 7-embodiment 11, and table 3 is the relevant parameter table of embodiment 12-embodiment 16, and table 4 is embodiment 17-the relevant parameter table of embodiment 21, table 5 is the relevant parameter table of embodiment 22-embodiment 26, and table 6 is the relevant parameter table of embodiment 27-embodiment 31. The production methods of hydrophilic propolis powder capsules in embodiment 2-embodiment 31 are all the same as in embodiment 1, so the process steps are not described repeatedly.

[0064] In Table 1-Table 6, the "concentration of edible ethanol" in step (1) refers to the volume percentage of ethanol in edible ethanol, and the "soaking time" in step (1) refers to the time for which propolis is soaked in edible ethanol. Time, the "stirring time" in step (1) refers to the time for stirring the mixture of propolis and edible ethanol. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com