Manufacturing method of upper structure of screw-retained implant

A production method and implant technology, applied in the fields of implantology, medical science, dentistry, etc., can solve problems such as difficult to achieve close precision, increased occlusal height, and poor reusability, so as to improve the close precision, eliminate occlusal heightened, and ensure The effect of passive positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

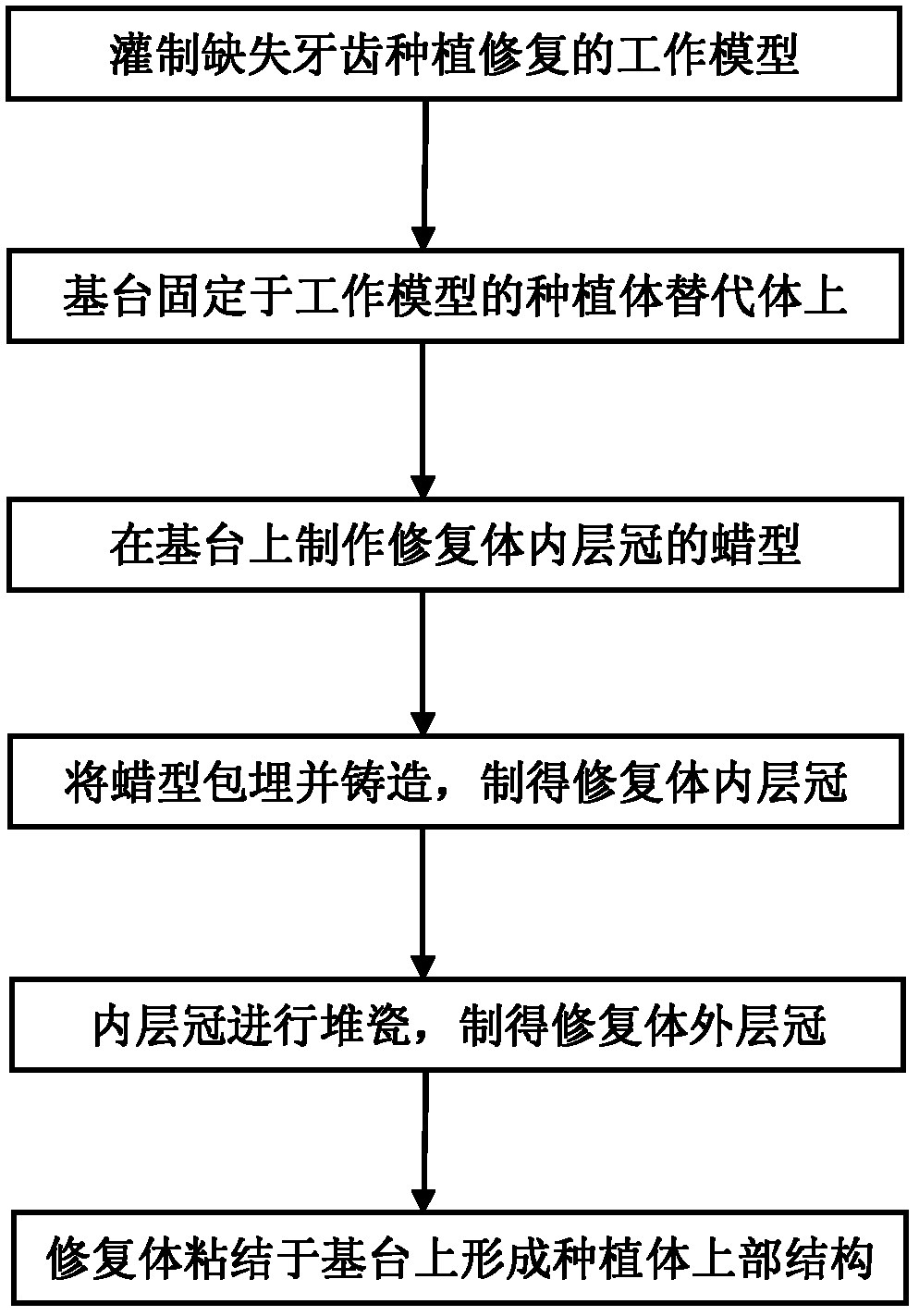

[0021] A method for manufacturing a screw-retained implant superstructure of the present invention comprises the following steps:

[0022] 1. Use the window-type impression method to take the impression, and fill the working model of the implant restoration of the missing tooth ( CAT No. 3912HL. Nobel Biocare, Yorba Linda, CA, USA);

[0023] Implant dentures include three indispensable components: implant nails (commonly known as implants) implanted in the upper and lower jaws, abutments connecting implants and restorations, restorations (porcelain teeth or all-ceramic teeth, used to restore The part of the patient's occlusal function is also the implant superstructure). The whole process can be roughly divided into two steps: the first step is implant surgery (the implant is implanted into the patient's jawbone by surgery); , because at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com