High-efficiency manufacturing method for intraocular lens with correction of high-order wavefront aberration

A technology of intraocular lens and wavefront aberration, applied in intraocular lens, eye implant, etc., can solve the problem that intraocular lens is not suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

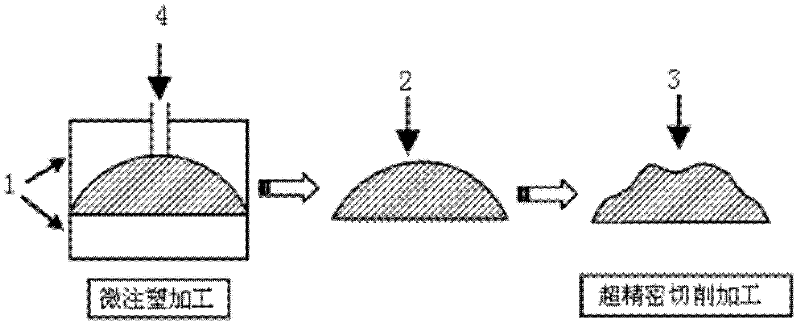

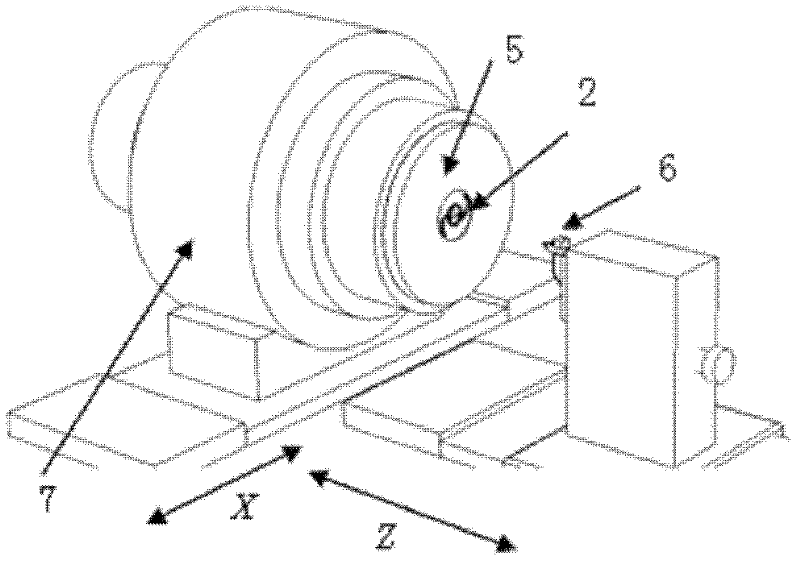

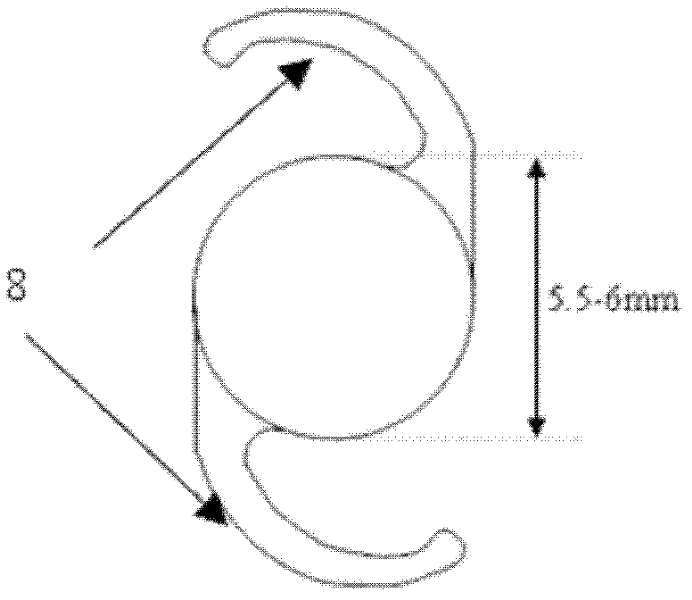

[0040] Example: For a common diameter of 6mm, the curvature is 0.141mm -1 The spherical base intraocular lens is processed for wavefront aberration correction. The specific correction amount required is measured by the Hartmann-Shack aberrometer developed by the Institute of Optoelectronic Technology, Chinese Academy of Sciences. The corresponding Zernike polynomial coefficients are the first 35 items. After micro-injection molding processing, the artificial lens substrate with the surface of Ra=18nm and Rt=99nm is obtained, and the material is medical PMMA material (polymethyl methacrylate). The substrate is fixed on the rotating spindle through a design fixture, and a diamond tool with a radius of 0.2mm is used for cutting. The processing program is designed according to the tool compensation method. The specific processing parameters are the spindle speed 72rpm, and the rough machining x-direction feed is 3.0mm. / min, the cutting depth is 2um each time, the cutting process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com