Purifier metal carrier core winding machine

A technology of metal carrier and core winding machine, which is applied in the direction of chemical instruments and methods, separation of dispersed particles, separation methods, etc., can solve the problems of large deviation in the degree of tightness of winding products, affect the quality of winding cores, and complex structures, etc., to improve production Efficiency and product quality, improved labor safety, precise core dimensions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

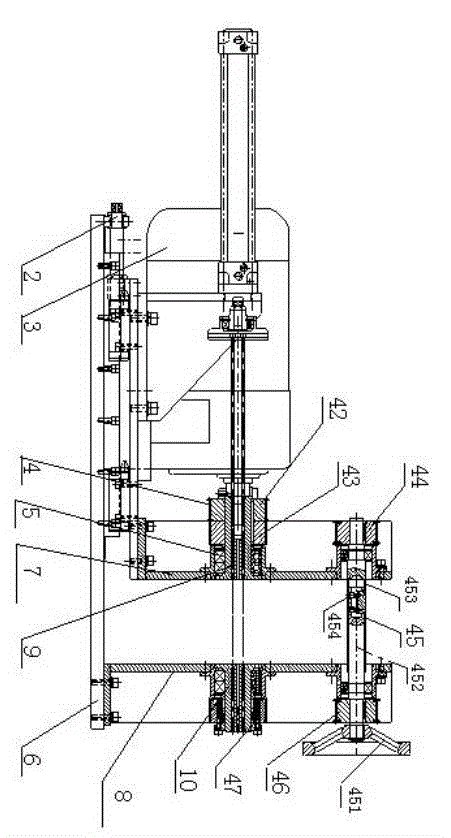

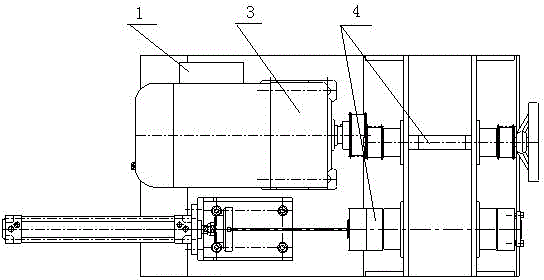

[0031] like figure 1 As shown, the present invention is mainly composed of the following parts: electrical control system 1, side baffle width adjustment device 2, motor reducer 3 providing winding power, toothed belt transmission system 4, reel system 5, and stand 6. A movable side plate 7 and a fixed side plate 8 are correspondingly arranged on the platform 6 , and the two side plates are correspondingly respectively pierced with reels that can drive the reel mandrel to wind. The fixed side plate 8 is vertically fixed on the stand 6; the movable side plate 7 can be driven by the side baffle width adjusting device 2, and moves horizontally along the stand 6 on the same central horizontal line as the fixed side plate 8.

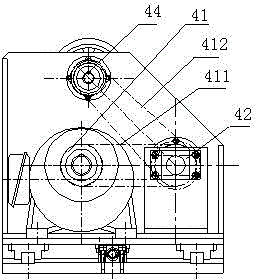

[0032] like figure 1 , figure 2As shown, the toothed belt transmission system as a whole has a π-shaped transmission structure, including three-stage transmission: the first-stage drive wheel 41 is installed on the output shaft of the motor reducer 3, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com