Device and method for converting mixed alcohol

A technology of mixing alcohols and mixed liquids, which is applied in the field of plasma synthesis chemistry to achieve high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

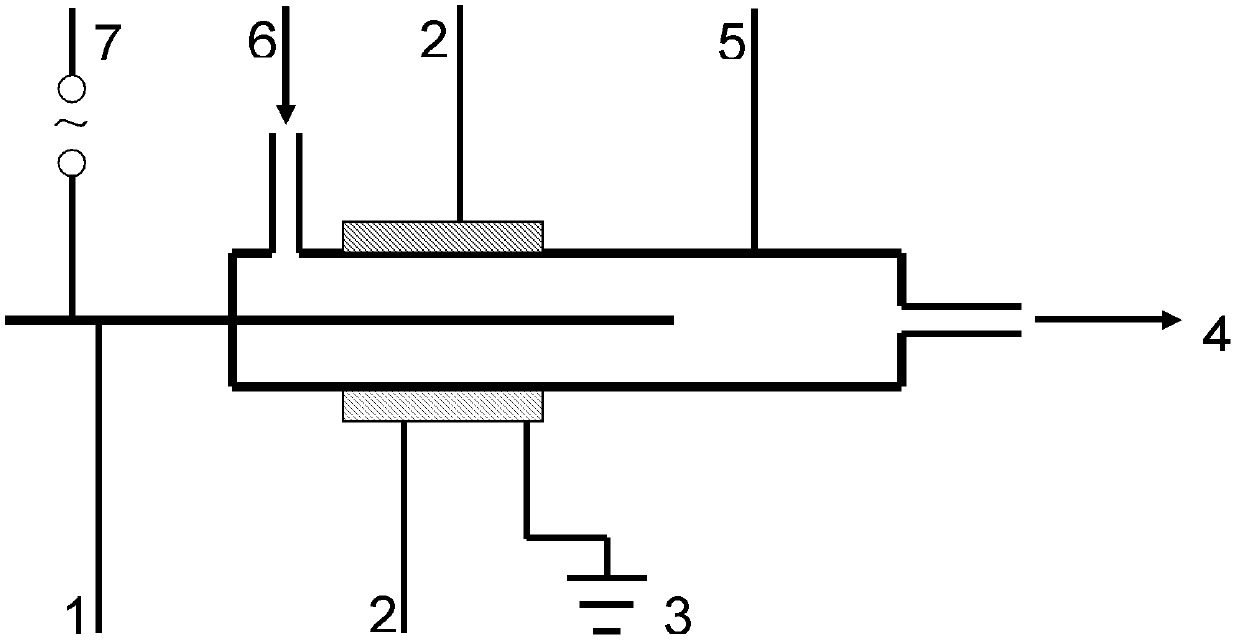

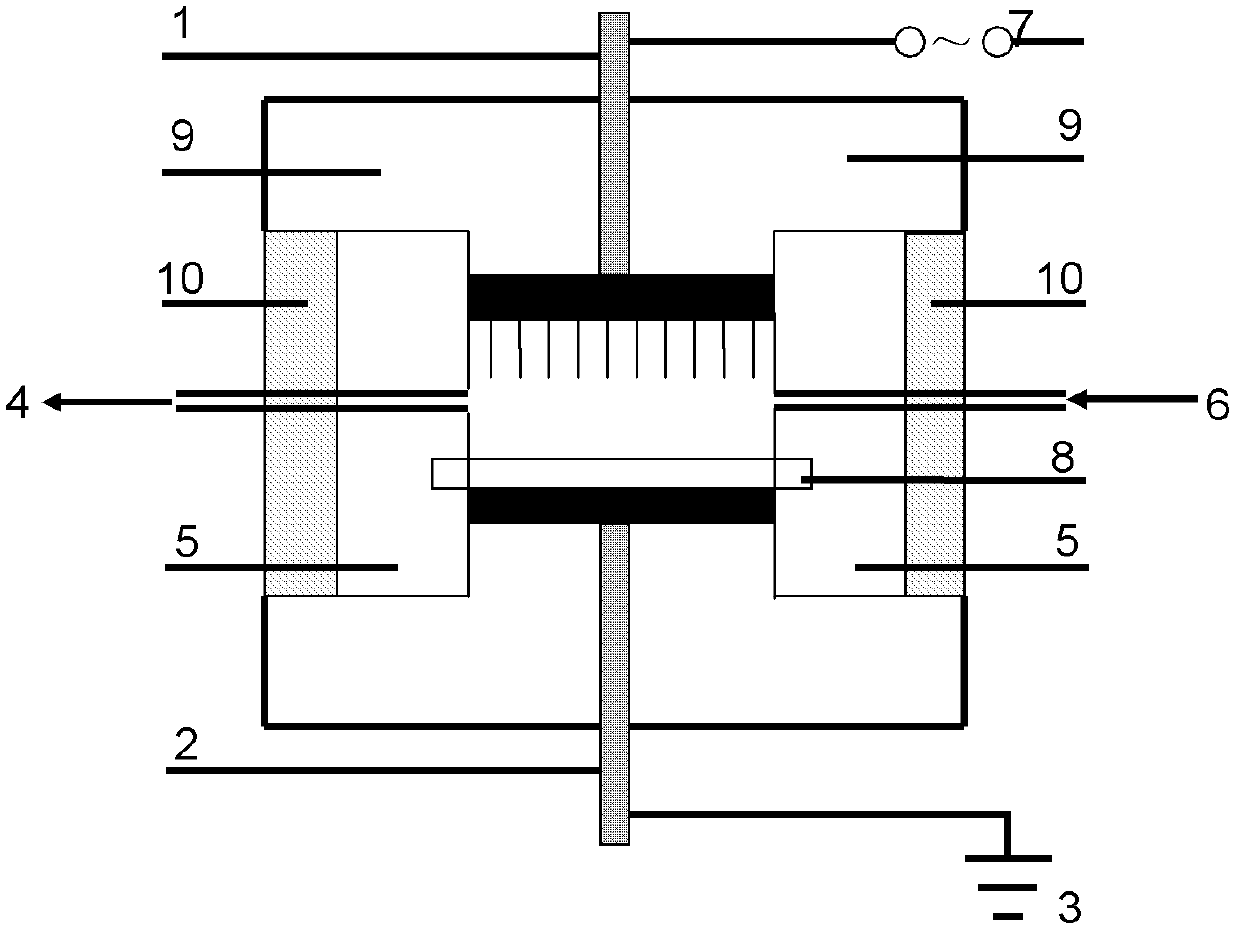

Embodiment 1

[0098] Using hydrogen as the carrier gas, the mixed solution of hydrogen, methanol and ethanol (85% methanol content, 15% ethanol content) is transported to the heat exchanger for vaporization, and then enters the line-barrel reactor. The feed molar ratio of hydrogen and mixed alcohol is 2.0, and the residence time of mixed alcohol in the discharge interval of the reactor is 2.0s; the shell of the line-barrel reactor (Fig. 1-1) also serves as a barrier medium, and its outer diameter is 12mm, the tube wall thickness is 1.0mm, the electrode spacing is 5mm, the high voltage pole electrode is white steel wire with a diameter of 2.0mm; The interval length is 200mm; when the discharge frequency and discharge power are kept unchanged at 7kHz and 20W respectively, the reaction conditions are normal temperature and pressure, and the material of the reactor shell is adjusted, the reaction result is:

[0099] Quartz glass, the conversion rate of methanol is 10.49%, the selectivity of eth...

Embodiment 2

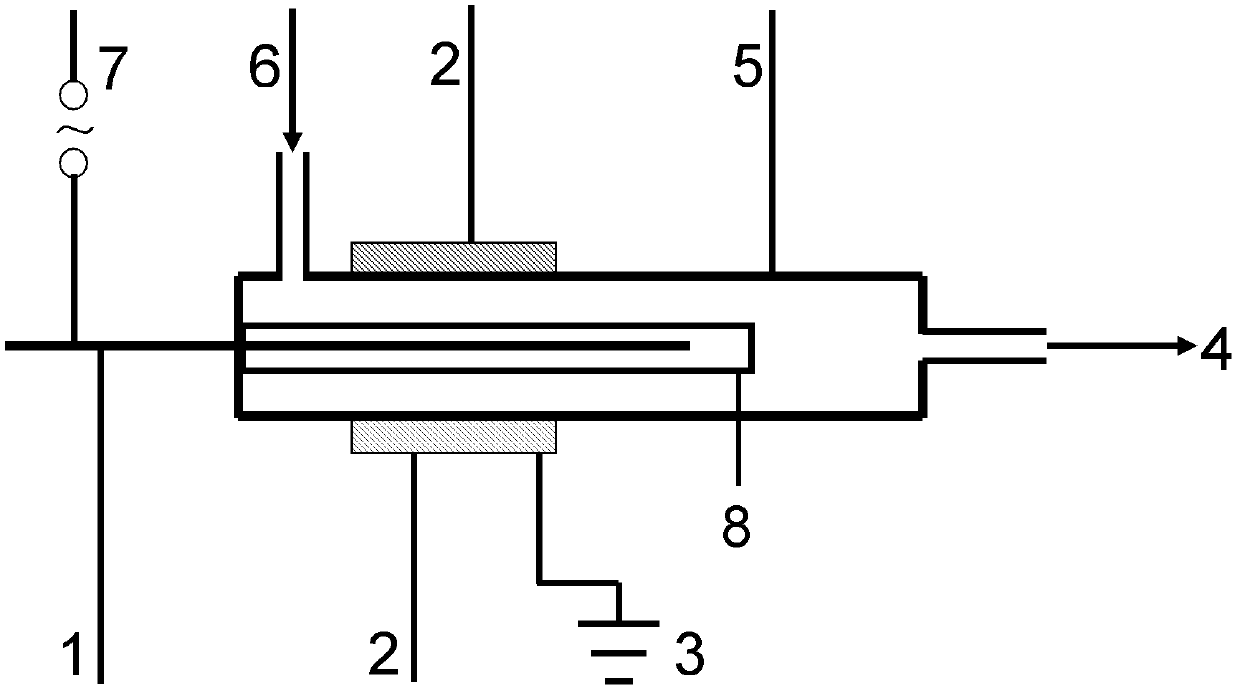

[0105]Repeat Example 1, but the reactor adopts a double dielectric barrier discharge reactor (Fig. 1-2), and its shell and inner casing are made of polytetrafluoroethylene, wherein the thickness of the inner barrier medium tube is 0.3mm, and the outer diameter is 3.0mm and the length is 300.0mm. Then the reaction result is: the conversion rate of methanol is 6.32%, the selectivity of ethylene glycol is 19.41%, and the selectivity of isopropanol, propanol, sec-butanol, isobutanol and n-butanol is respectively 2.78%, 3.23%, 3.56%, 4.21%, 3.12%.

[0106] This example shows that when the double barrier medium is used, the energy of the electrons generated by the discharge is further lowered, and the conversion rate of methanol is further lowered, while the selectivity of ethylene glycol is improved, while the selectivity of ethanol and n-propanol is reduced .

Embodiment 3

[0108] Repeat embodiment 2, but when total barrier medium thickness (sum of internal and external barrier medium thickness) changes, then reaction result is:

[0109] The thickness of the medium is 1.0mm, the conversion rate of methanol is 23.47%, the selectivity of ethylene glycol is 6.41%, the selectivity of isopropanol, propanol, sec-butanol, isobutanol and n-butanol are 2.18%, 3.56%, 2.48%, 3.37%, 2.61%.

[0110] The thickness of the medium is 1.5mm, the conversion rate of methanol is 18.75%, the selectivity of ethylene glycol is 8.72%, the selectivity of isopropanol, propanol, sec-butanol, isobutanol and n-butanol are 3.24%, 2.45%, 2.51%, 3.23%, 2.45%.

[0111] The medium thickness is 2.0mm, the conversion rate of methanol is 15.23%, the selectivity of ethylene glycol is 10.33%, the selectivity of isopropanol, propanol, sec-butanol, isobutanol and n-butanol are 2.88%, 2.57%, 3.24%, 2.45%, 3.42%.

[0112] The thickness of the medium is 3.0mm, the conversion rate of meth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com