Envelope fabric of an insulation board and a preparation process for the same

A preparation process and insulation board technology, which can be applied to other household appliances, lamination, building components, etc., can solve the problems of short service life, easy aging, flammability, etc., to ensure service life, improve aging resistance, The effect of breathability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

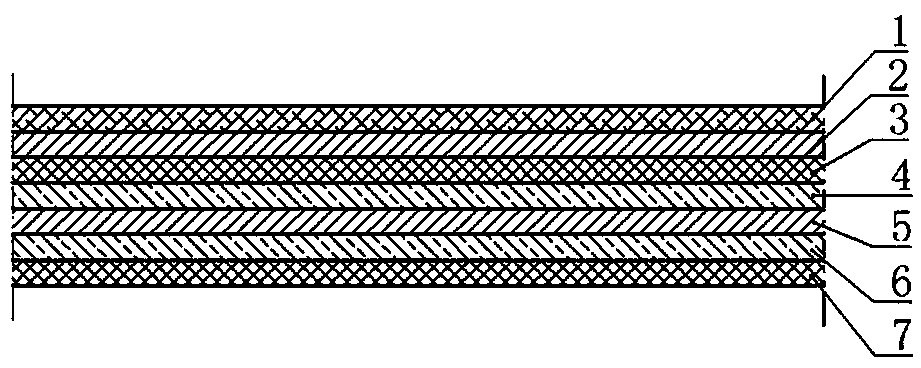

[0016] see figure 1 , an insulation board cover fabric of the present invention is characterized in that it comprises a glass fiber cloth layer 1, a first aluminum foil layer 2, a PET layer 3, and a first nylon layer sequentially compounded from outside to inside (from top to bottom in the figure). 4. The second aluminum foil layer 5, the second nylon layer 6 and the PE layer 7.

[0017] The specification of described fiberglass cloth 1 is 20-500g / m 2 The thickness of the first aluminum foil layer 2 and the second aluminum foil layer 5 is 5-20 microns; the thickness of the PET layer 3 is 8-30 microns; the thickness of the first nylon layer 4 and the second nylon layer 6 is 8-30 microns; the thickness of the PE layer 7 is 30-200 microns.

[0018] The preparation process of the insulation board cover fabric of the present invention comprises:

[0019] (1) Firstly, the glass fiber cloth layer 1 and the first aluminum foil layer 2 are composited. The specific composite method o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com