Production process for forming frosted effect on surfaces of gold and silver paperboards

A production process and frosting technology, used in printing, printing devices, etc., can solve problems such as batch scrap, difficult to control, and easy to explode color burst, so as to improve production efficiency, relieve production pressure, and solve the effect of burst color burst.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The process of forming a matte effect on the surface of 235 grams of gold cardboard comprises the following steps in turn:

[0018] (1) Install the transferred 235g gold card roll paper on the unwinding device 1 of the multi-color rotogravure printing machine;

[0019] (2) Introduce the gold cardboard into the printing device 2 for graphic printing;

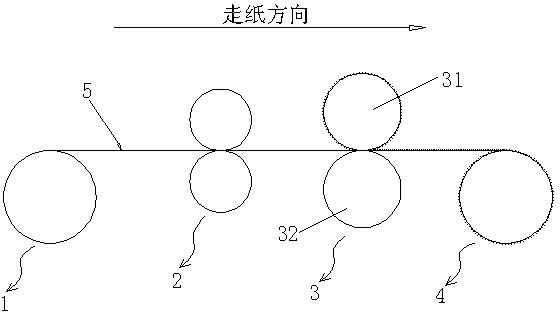

[0020] (3) Introduce the printed gold cardboard into the circular sand pressing device 3 for overprint sand pressing. The sand pressing device includes a heatable sand pressing base roller 31 on the upper side, a rubber bottom under the sand pressing base roller Roller 32, a frosted press plate is installed on the peripheral surface of the sand base roller, and the frosted press plate is a stainless steel plate with mesh pits imitating silk screen frosting effects engraved on the surface in advance, and the mesh pit area corresponds to the gold and silver cardboard In the pattern area, the depth of the mesh pit is 75μm. T...

Embodiment 2

[0023] The process of forming a matte effect on the surface of 240 grams of silver and gold cardboard includes the following steps in turn:

[0024] (1) Install the transferred 240g silver card roll paper on the unwinding device 1 of the multi-color rotogravure printing machine;

[0025] (2) Introduce the silver cardboard into the printing device 2 for graphic printing;

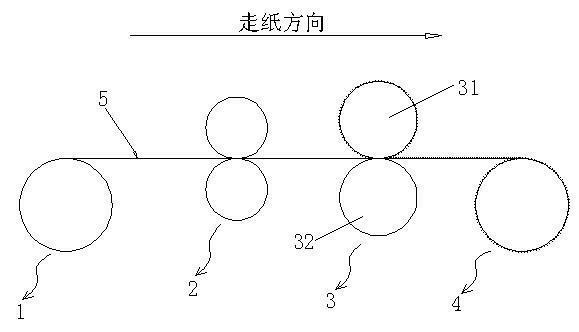

[0026] (3) Introduce the printed silver cardboard into the circular sand pressing device 3 for sand pressing. The sand pressing device includes a heatable sand pressing base roller 31 located on the upper side, and a rubber bottom roller located below the sand pressing base roller. 32. A frosted platen is installed on the circumference of the sand press base roller. The frosted platen is a stainless steel plate that is pre-engraved with mesh pits imitating the silk screen frosting effect. The area of the mesh pits corresponds to the non-pattern of gold and silver cardboard area, the depth of the anilox pit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com