Preparation method of nano-grade titanium dioxide

A titanium dioxide, nano-scale technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of changing the particle size, regulating the crystal phase, changing its shape, etc., achieving cheap raw materials, high separation efficiency, and simple post-processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

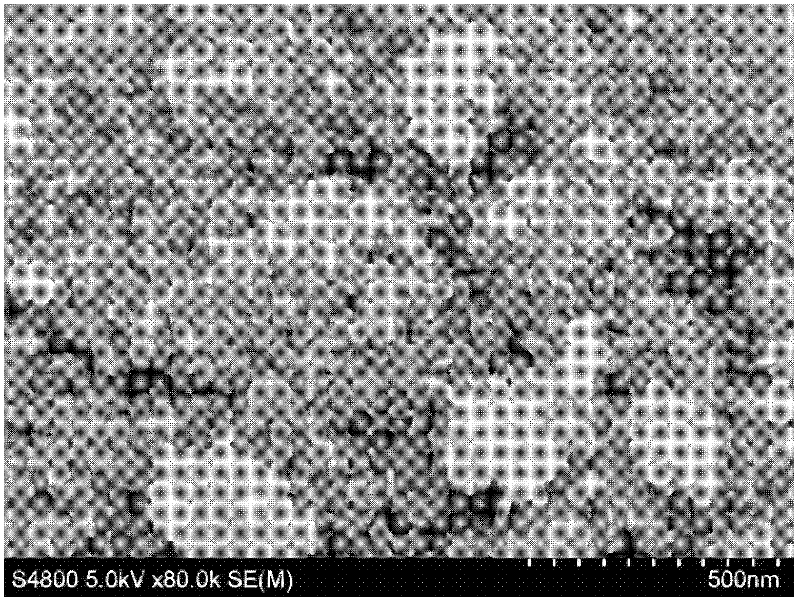

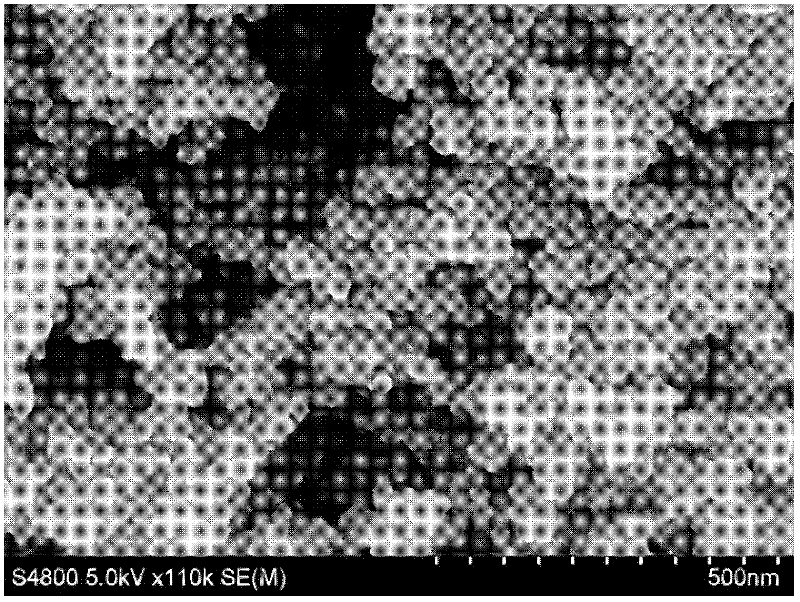

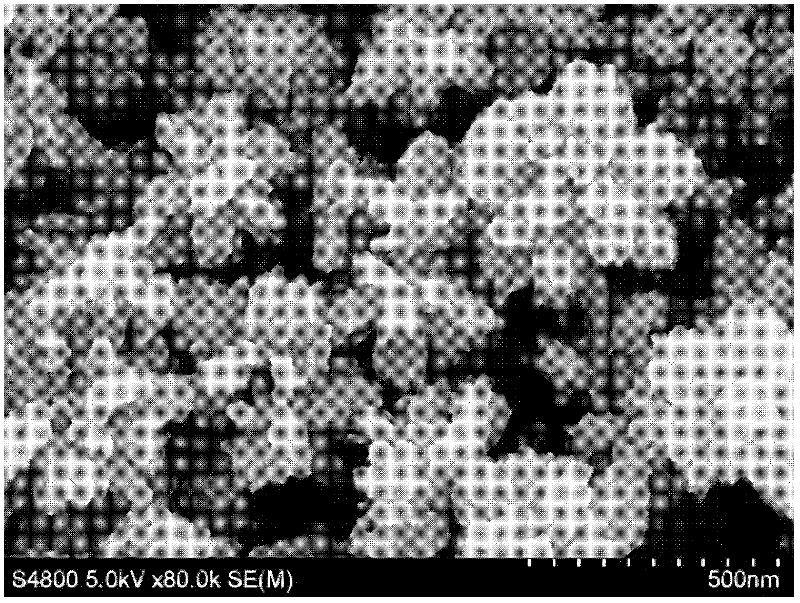

[0008] Specific embodiment 1: The preparation method of nano-scale titanium dioxide in this embodiment is carried out according to the following steps: adding polystyrene sulfonate to the titanium trichloride solution whose concentration is 0.01~0.06g / mL to obtain mixture A , wherein the concentration of polystyrene sulfonate in mixture A is 0.005-0.05 g / mL, then adjust the pH value to 0.1-5.0 with inorganic acid or inorganic base, and then carry out hydrothermal reaction at 110-180 °C for 0.5 ~24h, then filter or centrifuge to remove the liquid, wash the obtained solid with distilled water until the pH value is equal to 7, then wash with ethanol for 1~3 times, put it in a constant temperature blast drying oven, and keep the temperature at 60~80°C Dry for 5-12 hours; that is, nano-sized titanium dioxide is obtained.

[0009] Crystal phase and morphology table of nanoscale titanium dioxide obtained under different conditions in table 1

[0010]

[0011]

specific Embodiment approach 2

[0012] Embodiment 2: This embodiment differs from Embodiment 1 in that: the polystyrene sulfonate is sodium polystyrene sulfonate. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0013] Embodiment 3: This embodiment differs from Embodiment 2 in that: the average molecular weight of the sodium polystyrene sulfonate is 5,000-700,000. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com