Porous carbon material loaded with transition metal oxide as well as preparation method and application of porous carbon material

A technology of porous carbon materials and transition metals, applied in chemical instruments and methods, iron oxide, cobalt compounds, etc., to achieve the effects of adjustable morphology, avoiding pollution and corrosion, and large surface modifiable characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Example 1 Preparation of boric acid / CuO-porous carbon / glassy carbon electrode

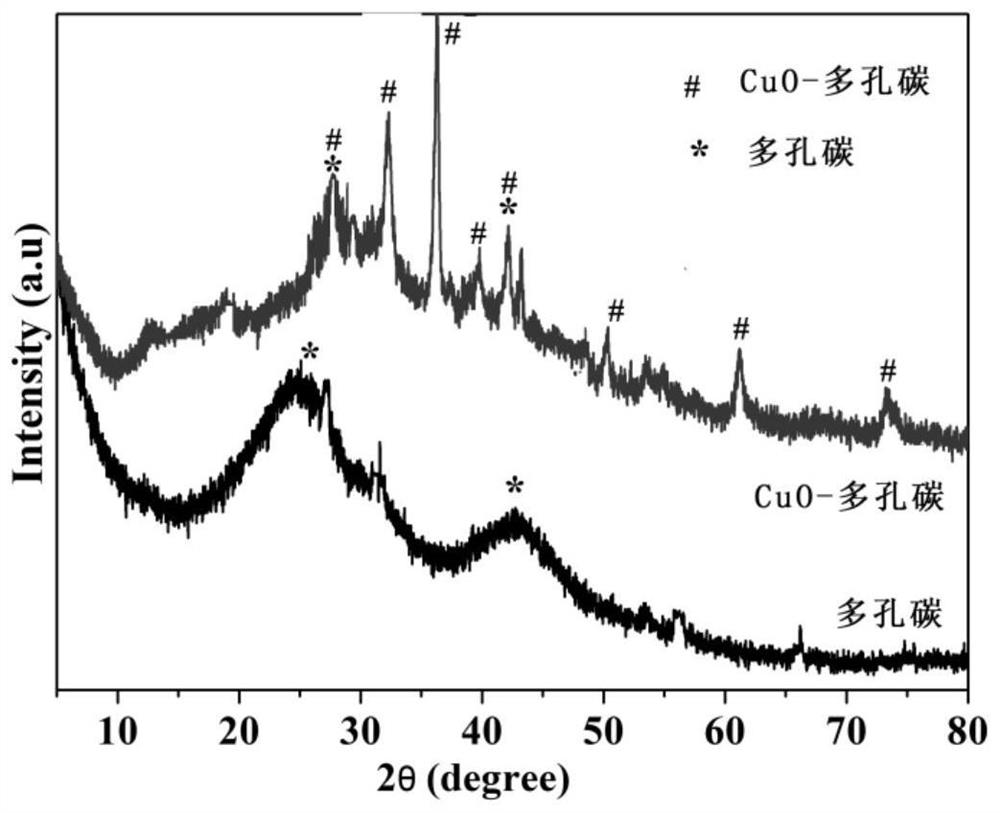

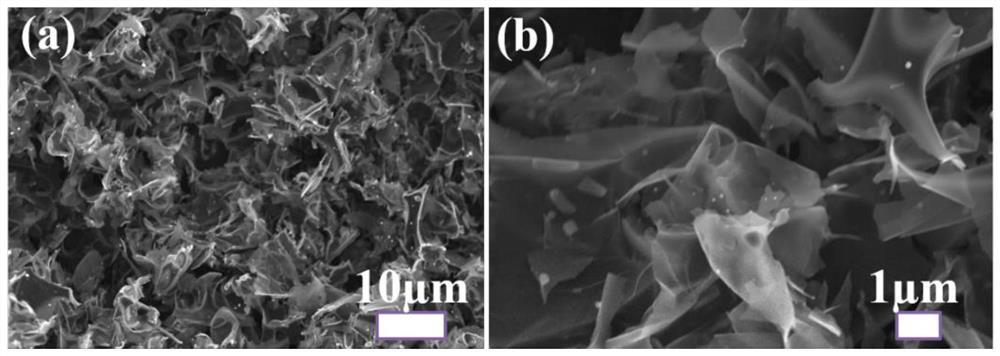

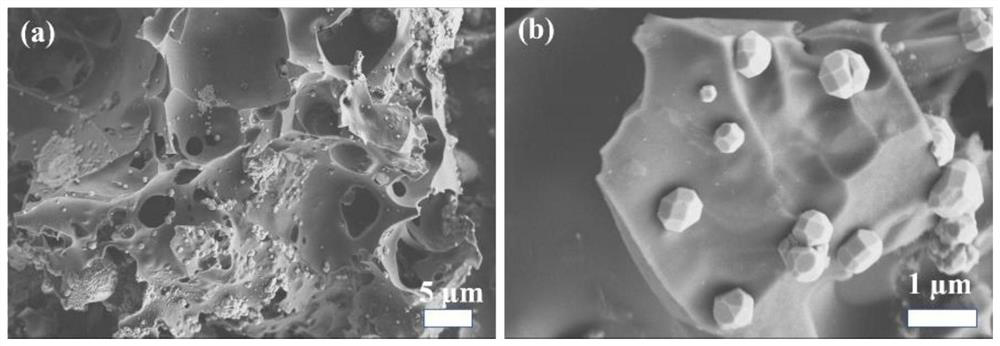

[0044] (1) Preparation of CuO-porous carbon

[0045] Mix 1 g of coal tar pitch (purchased from Hebei Fengtaiyuan Energy Technology Co., Ltd.), 3 g of sodium chloride, and 1 g of basic copper carbonate, dissolve it in 50 mL of nitrogen-methylpyrrolidone solution, and stir it magnetically for 3 h at 80 ° C. The solvent in the reaction system was evaporated to dryness to obtain a gray-black solid. Among them, the solubility of coal tar pitch in nitrogen methyl pyrrolidone is 20g / L.

[0046] The gray-black solid was placed in a nitrogen atmosphere, the heating rate was controlled to be 3°C / min, raised to 700°C, and the high temperature was maintained at 700°C for 3 hours to obtain a black solid. The black solid was washed with deionized water, filtered, and vacuum-dried to obtain 1.5 g of porous carbon material loaded with copper oxide, namely CuO-porous carbon, which had a hierarchical pore s...

Embodiment 2

[0057] Example 2 boric acid / Co 3 o 4 - Preparation of porous carbon / glassy carbon electrodes

[0058] (1) Preparation of Co 3 o 4 - porous carbon

[0059] 2g of petroleum pitch (purchased from Hebei Fengtaiyuan Energy Technology Co., Ltd.), 8g of potassium chloride and 4g of basic cobalt carbonate were mixed, dissolved in 80mL of tetrahydrofuran solution, and magnetically stirred at 100°C for 5h. The solvent in the reaction system was evaporated to dryness to obtain a gray-black solid. Among them, the solubility of petroleum pitch in tetrahydrofuran is 25g / L.

[0060] Place the gray-black solid in a nitrogen atmosphere, control the heating rate to 5°C / min, raise it to 800°C, and maintain the high temperature of 800°C for 4h to obtain a black solid. The black solid was washed with deionized water, filtered, and vacuum-dried to obtain 4.7g of porous carbon materials loaded with tricobalt tetroxide, i.e. Co 3 o 4 - Porous carbon, the composite carbon material has a hierar...

Embodiment 3

[0066] Embodiment 3 boric acid / Fe 2 o 3 - Preparation of porous carbon / glassy carbon electrodes

[0067] (1) Preparation / Fe 2 o 3 - porous carbon

[0068] 2g of petroleum pitch (purchased from Hebei Fengtaiyuan Energy Technology Co., Ltd.), 8g of potassium chloride and 4g of iron carbonate were mixed, dissolved in 80mL of tetrahydrofuran solution, and magnetically stirred at 100°C for 5h. The solvent in the reaction system was evaporated to dryness to obtain a gray-black solid. Among them, the solubility of petroleum pitch in tetrahydrofuran is 25g / L.

[0069] Place the gray-black solid in a nitrogen atmosphere, control the heating rate to 5°C / min, raise it to 800°C, and maintain the high temperature of 800°C for 4h to obtain a black solid. The black solid was washed with deionized water, filtered, and vacuum-dried to obtain 4.5 g of porous carbon materials loaded with iron oxide, namely Fe 2 o 3 - Porous carbon, the composite carbon material has a hierarchical pore st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com