Method for manufacturing Z-pin reinforced carbon/carbon composite prefabricated part and Z-pin freezing pultrusion and implantation integrated machine

A carbon composite material and a manufacturing method technology, applied in the field of carbon/carbon composite material reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

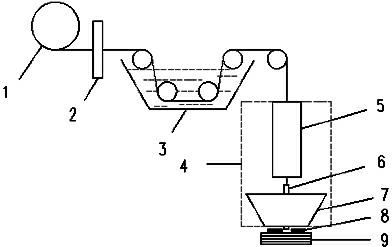

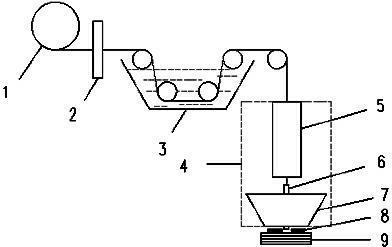

[0015] Specific implementation mode one: combine figure 1 This embodiment will be described. Put the infiltration medium whose boiling point is lower than the minimum curing temperature of the prepreg and does not react with the carbon fiber, such as water, alcohol, acetone and other easily removable media, into the immersion tank 3, and place the carbon fiber T300 in the yarn unwinding device 1. The fiber guiding device 2 guides into the immersion tank 3, and the carbon fiber soaked in the medium is formed into a cylindrical frozen Z-pin through the pultrusion die 5 of the ultra-low temperature cooling chamber, and the frozen Z-pin is implanted with the implant head 7 of the ultra-low temperature cooling chamber. Into the carbon fiber woven cloth 9, according to the physical properties of the infiltration medium, the Z-pin reinforced carbon fiber woven cloth is raised to room temperature or slightly increased temperature under reduced pressure, so that the infiltration mediu...

specific Embodiment approach 2

[0016] Specific Embodiment 2: In combination with Specific Embodiment 1, this embodiment will be described. The method in the first embodiment is also applicable to other types of carbon fibers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com