Preparation method of high-efficiency liquid fertilizer

A liquid fertilizer, high-efficiency technology, applied in the direction of fertilizer mixture, fertilization device, application, etc., can solve the problems of inconspicuous effect, uneven quality of liquid fertilizer, etc., achieve good control effect, improve utilization rate, and reduce the effect of disease occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] Embodiment 1, a kind of high-efficiency liquid fertilizer preparation method, in this method 40% amino acid powder, zinc sulfate, manganese sulfate, boric acid, molybdenum acid, copper sulfate, ferrous sulfate, KOM and water are mixed and thrown in the corrosion-resistant reactor, The percentage of each material in the feed is:

[0014]

[0015] The water adopts ordinary tap water, which is softened by SG series softened water processor. Stir while adding samples in the corrosion-resistant reaction kettle, judge the complete dissolution of various raw materials according to the specified time, and complete the chelation and compounding of nutrients, then make product appearance judgment and pH value judgment and adjustment, and filter into a clean storage tank .

Embodiment 2

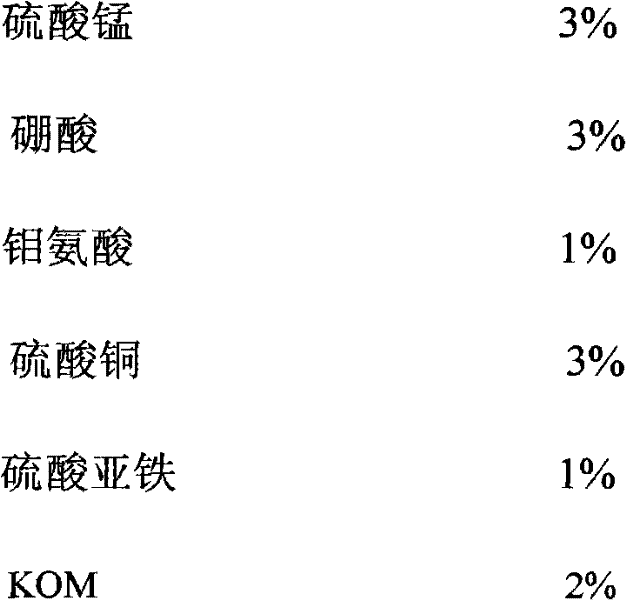

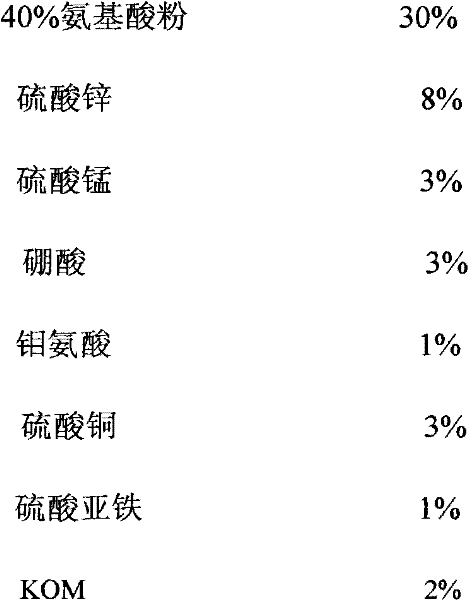

[0016] Embodiment 2, a kind of high-efficiency liquid fertilizer preparation method, in this method, 40% amino acid powder, zinc sulfate, manganese sulfate, boric acid, molybdenum acid, copper sulfate, ferrous sulfate, KOM and water are mixed and thrown into the corrosion-resistant reaction kettle, The percentage of each material in the feed is:

[0017]

[0018]

[0019] The water adopts ordinary tap water, which is softened by SG series softened water processor. Stir while adding samples in the corrosion-resistant reaction kettle, judge the complete dissolution of various raw materials according to the specified time, and complete the chelation and compounding of nutrients, then make product appearance judgment and pH value judgment and adjustment, and filter into a clean storage tank .

Embodiment 3

[0020] Embodiment 3, a kind of high-efficiency liquid fertilizer preparation method, in this method, 40% amino acid powder, zinc sulfate, manganese sulfate, boric acid, molybdenum acid, copper sulfate, ferrous sulfate, KOM and water are mixed and thrown into the corrosion-resistant reaction kettle, The percentage of each material in the feed is:

[0021]

[0022] The water adopts ordinary tap water, which is softened by SG series softened water processor. Stir while adding samples in the corrosion-resistant reaction kettle, judge the complete dissolution of various raw materials according to the specified time, and complete the chelation and compounding of nutrients, then make product appearance judgment and pH value judgment and adjustment, and filter into a clean storage tank .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com