High-performance organic silicon electronic pouring sealant and preparation method and application thereof

A technology of silicone and potting glue, applied in chemical instruments and methods, adhesives, other chemical processes, etc., can solve the problems of poor mechanical properties, low light transmittance, etc., to solve the problems of poor light transmittance and mechanical properties, improve The effect of light transmittance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

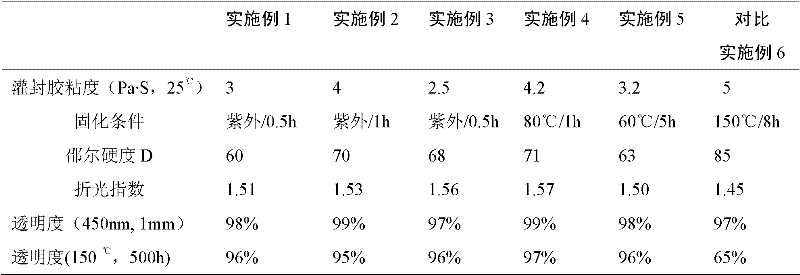

Examples

Embodiment 1

[0042] A preparation method for high-performance organosilicon electronic potting glue, comprising the following steps:

[0043] (1) Mix 30 parts of diphenyldichlorosilane, 10 parts of dimethyldichlorosilane, 20 parts of vinyltrichlorosilane and 20 parts of 3-(acryloyloxy)propyltrimethoxy Silane was mixed and dropped into 200 parts of toluene solvent, then slowly dropped into 60 parts of water, reacted at 140°C for 8 hours, and removed the solvent under reduced pressure to obtain a colorless and transparent acryloyloxyolefin-based organosilicon precursor oligomer A 1 .

[0044] (2) Mix 30 parts of phenyltrichlorosilane, 20 parts of dimethyldichlorosilane and 30 parts of 3-mercaptopropyltrimethoxysilane into 150 parts of toluene solvent by weight, and then slowly drop into 70 parts of water, reacted at 140°C for 8 hours, and removed the solvent under reduced pressure to obtain a colorless and transparent mercapto organosilicon precursor oligomer B 1 .

[0045] (3) 60 parts o...

Embodiment 2

[0048] A preparation method for high-performance organosilicon electronic potting glue, comprising the following steps:

[0049] (1) Mix 50 parts of phenyltrichlorosilane, 25 parts of methylvinyldichlorosilane and 15 parts of 3-(acryloyloxy)propyltriethoxysilane into 250 parts of toluene in proportion by weight Solvent, then slowly drop 80 parts of water, react at 130°C for 5 hours, remove the solvent under reduced pressure, and obtain a colorless and transparent acryloyloxy olefin-based organosilicon precursor oligomer A 2 .

[0050] (2) Mix 40 parts of diphenyldichlorosilane, 20 parts of dimethyldichlorosilane and 30 parts of 3-mercaptopropyltriethoxysilane into 200 parts of toluene solvent by weight, then slowly Drop in 90 parts of water, react at 120°C for 6 hours, remove the solvent under reduced pressure, and obtain a colorless and transparent mercapto organosilicon precursor oligomer B 2 .

[0051] (3) 50 parts of acryloxy olefin-based silicone precursor oligomer A ...

Embodiment 3

[0054] A preparation method for high-performance organosilicon electronic potting glue, comprising the following steps:

[0055] (1) Mix 40 parts of diphenylsilanediol, 50 parts of methylvinyldichlorosilane and 20 parts of 3-(methacryloyloxy)propylmethyldimethoxysilane in proportion by weight Add 20 parts of toluene solvent dropwise, add 5 parts of triethylamine, react at 80°C for 5 hours, remove the solvent under reduced pressure, and obtain a colorless and transparent acryloyloxyolefin-based organosilicon precursor oligomer A 3 .

[0056] (2) 40 parts of diphenylsilanediol and 50 parts of 3-mercaptopropylmethyldimethoxysilane were mixed and dropped into 30 parts of toluene solvent according to the proportion by weight, and 4 parts of triethylamine were added, at 90°C After reacting for 6 hours, the solvent was removed under reduced pressure to obtain a colorless and transparent mercapto organosilicon precursor oligomer B 3 .

[0057] (3) 50 parts of acryloxy olefin-based ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com