Rubber used on shaft sleeve assembly of fan

A technology of shaft sleeves and components, applied in the field of rubber, can solve problems such as poor heat resistance, low aging resistance, low bonding strength, and long vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

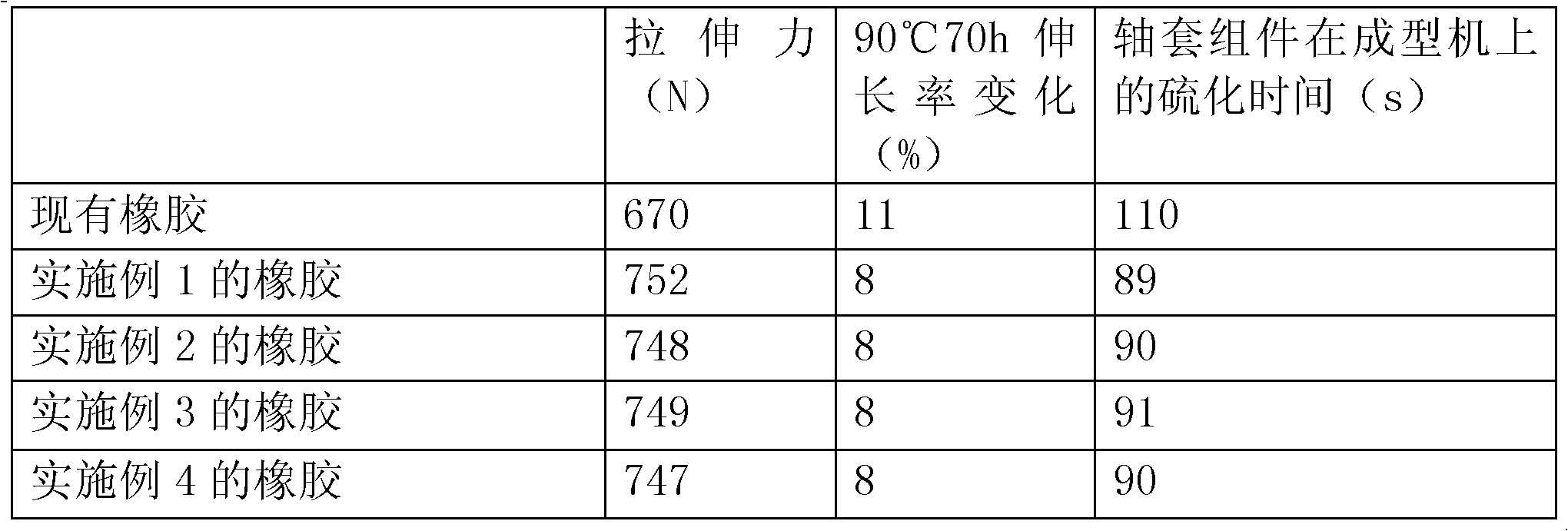

Examples

Embodiment 1

[0013] The rubber used on the shaft sleeve assembly of a fan is obtained by mixing and vulcanizing the following components in parts by mass: 100 parts of nitrile rubber, 5 parts of zinc oxide, 2 parts of stearic acid, 0.7 part of sulfur, and 1 part of feed agent TMTD, 1.5 parts of vulcanization accelerator DM, 37.5 parts of semi-reinforcing carbon black, 13 parts of carbon black 330, 20 parts of barium sulfate, 5 parts of vaseline, 1 part of anti-aging agent 4010NA.

[0014] The weight of 1 part in the above components is 1 kg. The manufacturing process of the rubber used on the shaft sleeve assembly of the fan is as follows: the above-mentioned nitrile rubber, zinc oxide, stearic acid, sulfur, accelerator TMTD, vulcanization Accelerator DM, semi-reinforcing carbon black, carbon black 330, barium sulfate, vaseline and anti-aging agent 4010NA are put into the internal mixer for banburying, and the rubber block after banburying is put into the open mixer to open, and then pulled...

Embodiment 2

[0016] The rubber used on the shaft sleeve assembly of a fan is obtained by mixing and vulcanizing the following components in parts by mass: 100 parts of nitrile rubber, 4 parts of zinc oxide, 1 part of stearic acid, 0.6 part of sulfur, and 0.9 parts of TMTD, 1.4 parts of vulcanization accelerator DM, 36 parts of semi-reinforcing carbon black, 11 parts of carbon black 330, 19 parts of barium sulfate, 4 parts of vaseline, 0.9 parts of anti-aging agent 4010NA. Manufacturing process is identical with embodiment 1.

Embodiment 3

[0018] The rubber used on the shaft sleeve assembly of a fan is obtained by mixing and vulcanizing the following components in parts by mass: 100 parts of nitrile rubber, 6 parts of zinc oxide, 3 parts of stearic acid, 0.8 part of sulfur, and 1.2 parts of TMTD, 1.8 parts of vulcanization accelerator DM, 40 parts of semi-reinforcing carbon black, 15 parts of carbon black 330, 22 parts of barium sulfate, 6 parts of Vaseline, 1.2 parts of anti-aging agent 4010NA. Manufacturing process is identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com