Environment-friendly carpet

An environment-friendly, carpet-based technology, applied to carpets, etc., can solve problems such as easy cracking, poor foot feel, and easy dissolution, and achieve good temperature resistance and good foot feel.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

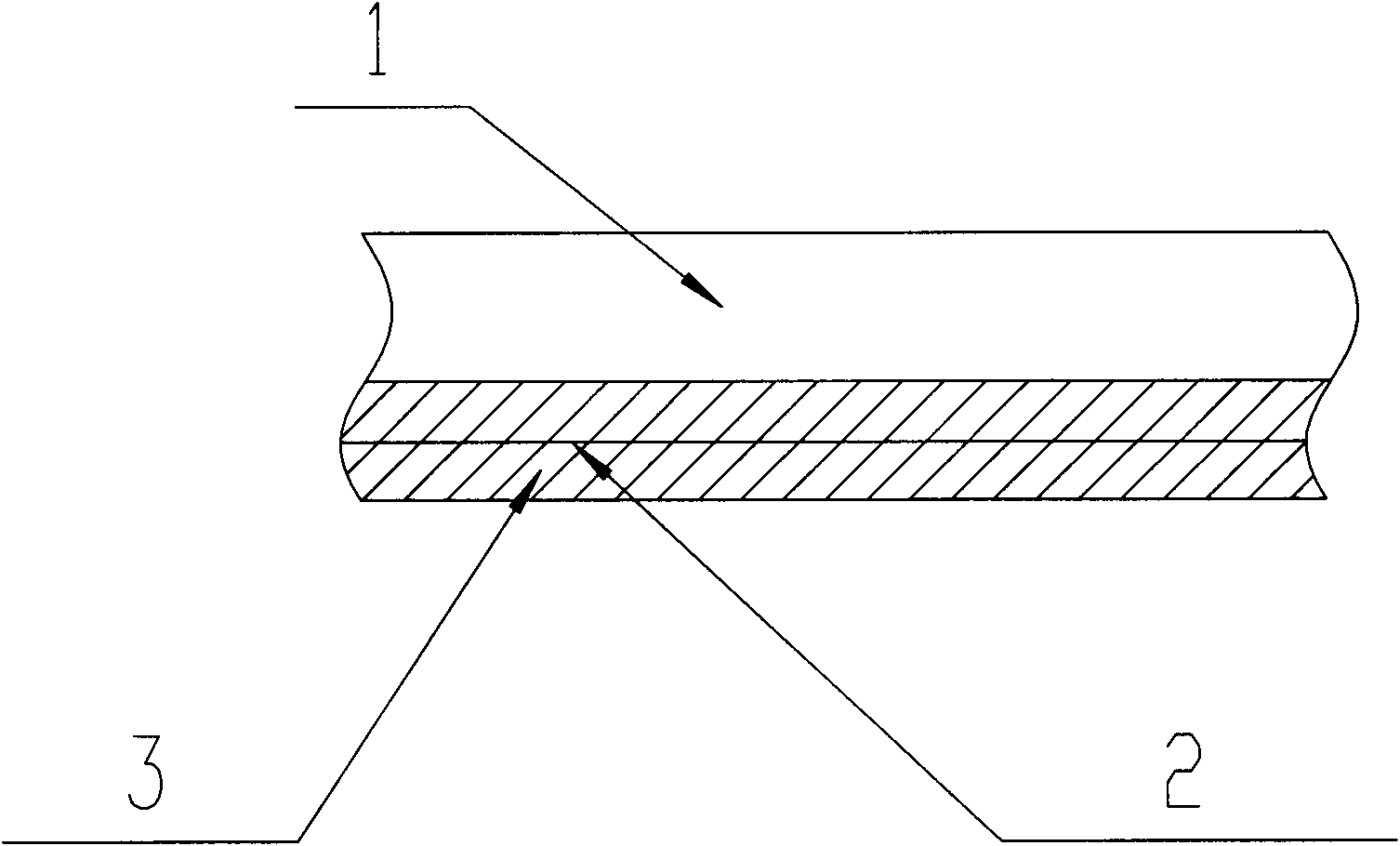

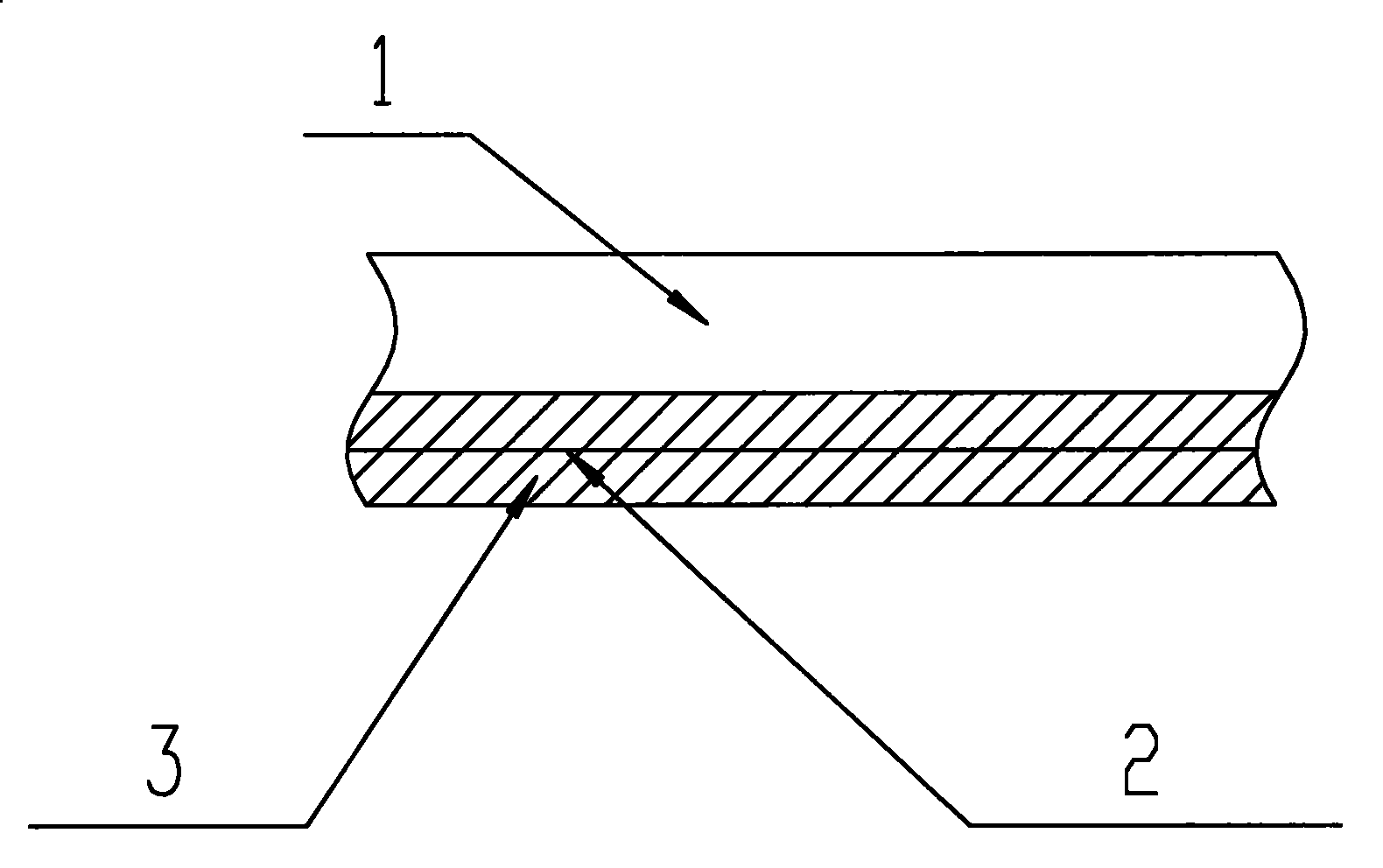

Image

Examples

Embodiment 1

[0026] Embodiment 1 prepares a kind of environment-friendly type carpet

[0027] The formula of the lower backing glue is: 200 kg of PVC paste resin, 700 kg of 100-mesh calcium carbonate, 180 kg of dioctyl terephthalate (DOTP), 2 kg of heat stabilizer, 15 kg of viscosity reducer, and 1 kg of carbon black.

[0028] The heat stabilizer is a liquid calcium zinc stabilizer.

[0029] The viscosity reducer is PVC viscosity reducer D80.

[0030] The preparation steps are as follows:

[0031] (1) Preparation of PVC adhesive material: PVC paste resin, dioctyl terephthalate, heat stabilizer, viscosity reducer, calcium carbonate and carbon black are added in the agitator successively, stirred, and the speed of the agitator is controlled at 120 rev / min, stirring time is 50 minutes;

[0032] (2) Put the above-mentioned configured PVC backing material on the Teflon conveyor belt twice before and after the bifurcation valve, and the first backing will pass the pressure roller to flatten t...

Embodiment 2

[0039] Embodiment 2 prepares a kind of environment-friendly type carpet

[0040] The formula of the bottom adhesive is: 150 kg of PVC paste resin, 800 kg of 120-mesh calcium carbonate, 160 kg of dioctyl terephthalate, 2 kg of heat stabilizer, 10 kg of viscosity reducer, and 1 kg of carbon black.

[0041] The heat stabilizer is a liquid calcium zinc stabilizer.

[0042] The viscosity reducer is PVC viscosity reducer D80.

[0043] The preparation steps are as follows:

[0044] (1) Preparation of PVC adhesive material: PVC paste resin, dioctyl terephthalate, heat stabilizer, viscosity reducer, calcium carbonate and carbon black are added in the agitator successively, stirred, and the speed of the agitator is controlled at 60 rev / min, stirring time is 40 minutes;

[0045] (2) Put the above-mentioned configured PVC adhesive material on the Teflon conveyor belt twice before and after the bifurcation valve, and the first adhesive will pass the pressure roller to flatten the PVC ad...

Embodiment 3

[0047] Embodiment 3 prepares a kind of environment-friendly type carpet

[0048] The formula of the lower adhesive is: 250 kg of PVC paste resin, 600 kg of 100-mesh calcium carbonate, 200 kg of dioctyl terephthalate, 1 kg of heat stabilizer, 20 kg of viscosity reducer, and 2 kg of carbon black.

[0049] The heat stabilizer is a liquid calcium zinc stabilizer.

[0050] The viscosity reducer is PVC viscosity reducer D80.

[0051] The preparation steps are as follows:

[0052] (1) Preparation of PVC adhesive material: PVC paste resin, dioctyl terephthalate, heat stabilizer, viscosity reducer, calcium carbonate and carbon black are added in the agitator successively, stirred, and the speed of the agitator is controlled at 180 rev / min, stirring time is 60 minutes;

[0053](2) Put the above-mentioned configured PVC adhesive material on the Teflon conveyor belt twice before and after the bifurcation valve, and the first adhesive will pass the pressure roller to flatten the PVC adh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap