Purification and purification equipment in the pyrolysis gasification system of biomass waste resources

A waste resource, pyrolysis gasification technology, applied in the direction of combustible gas purification, liquid scrubbing gas purification, combustible gas purification/transformation, etc., can solve the problems of low purification efficiency, secondary pollution, etc., achieve less space occupation and improve utilization The effect of high efficiency and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

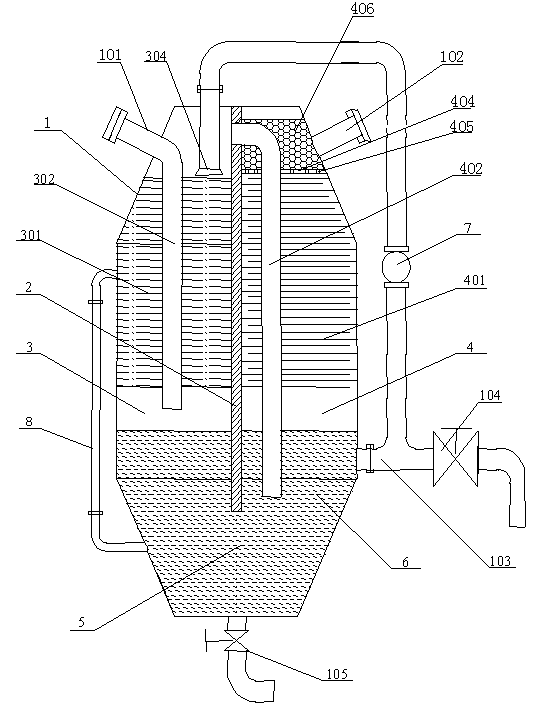

[0023] In order to further illustrate the technical means adopted by the present invention to achieve the predetermined purpose of the invention, the following describes the technical solutions according to the present invention in detail with reference to the accompanying drawings and preferred embodiments.

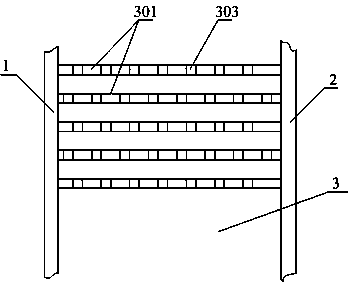

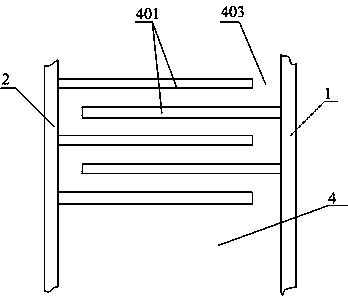

[0024] The purification and purification equipment in the pyrolysis and gasification system of biomass waste resources includes a closed container 1, and the size and shape of the container 1 can be set as required. The container 1 is provided with an air inlet 101 and an air outlet 102. After the mixed gas produced by the gasification system is condensed, the gas is pressed into the purification and purification equipment from the air inlet 101 by the gas conveying equipment, and flows out from the air outlet 102 for transportation. to the gas storage device or the user. In this technical solution, a vertical partition 2 is arranged in the container 1 , and the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com