Device for detecting in-plane error in micro/nano device out-of-plane motion test and compensating method

A motion error and motion measurement technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve problems affecting the reliability of measurement results, etc., and achieve the effects of avoiding errors, simple use, and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The in-plane motion error detection device and compensation method in the out-of-plane motion measurement of the micro-nano device of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings.

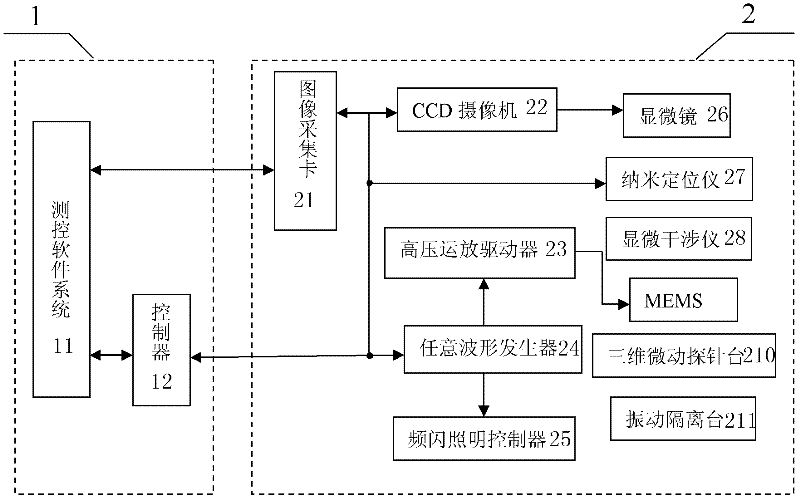

[0040] Such as figure 1 As shown, the in-plane motion error detection device in the out-of-plane motion measurement of micro-nano devices of the present invention has a control and image processing unit 1, and a phase-shift micro-interference system 2 connected to the control and image processing unit 1 , wherein, the control and image processing unit 1 is composed of a computer, and the phase-shift micro-interference system 2 includes:

[0041] Sequentially set up for obtaining the image of the micro-nano device 29 under test: a vibration isolation table 211, a three-dimensional micro-motion probe station 210, a micro-nano device under test 29, a micro-interferometer 28, a nanopositioner 27 and a microscope 26;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com