Method for making micrometer scale speckle

A manufacturing method and speckle technology, which are applied to devices for coating liquid on surfaces, measuring devices, instruments, etc., can solve the problems of high manufacturing cost, complicated process, difficult to control speckle size, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

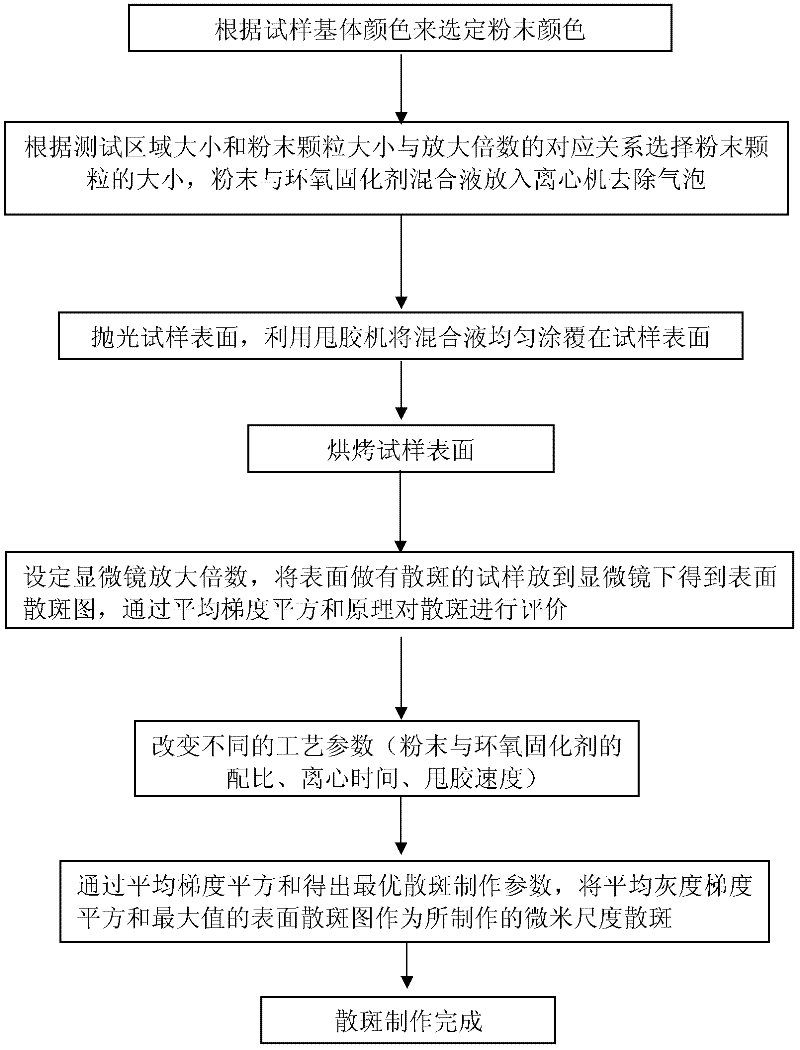

Method used

Image

Examples

example

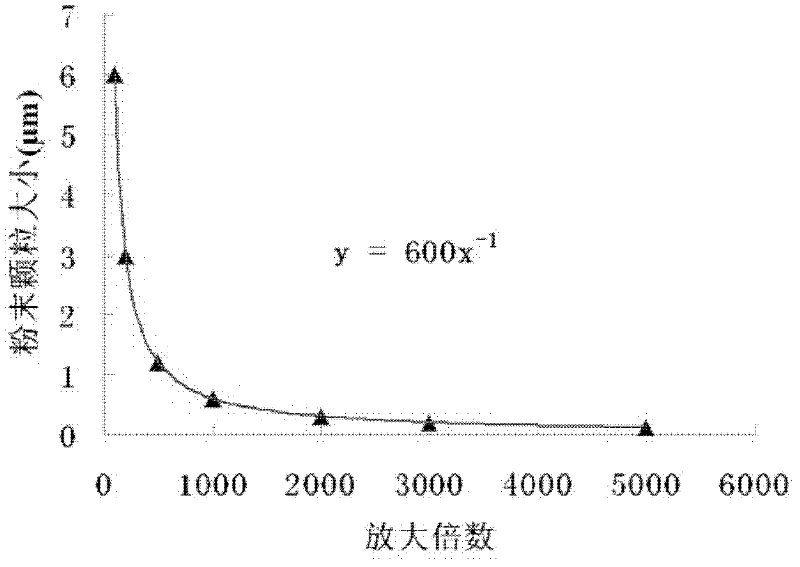

[0041] The material of the test piece is glass flakes, graphite powder is selected considering the color of the glass flakes, and the magnification corresponding to the super depth-of-field optical microscope is selected according to the size of the test area. Take 2.8. according to figure 2 Correspondence between powder particle size and magnification Select graphite powder with corresponding particle size. In the experiment, select the magnification as 200X and the powder particle size as 3pixel. The epoxy curing agent is Xy508 room temperature curing adhesive Group A and Group B (mixing ratio 3:1). The relationship between the epoxy curing agent solution and powder by volume and mass ratio and the sum of the squares of the average gray gradient of the speckle image is shown in Table 1:

[0042] Table 1

[0043]

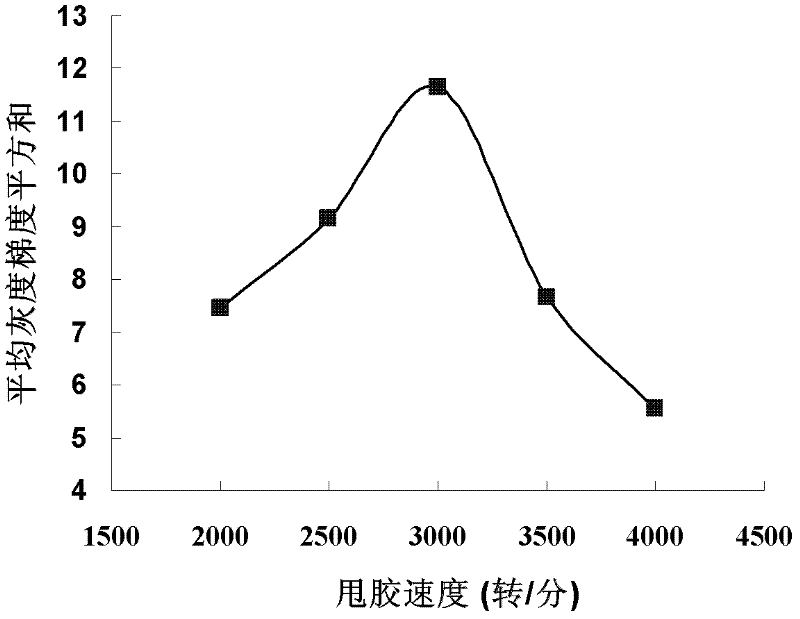

[0044] Therefore, the epoxy curing agent solution and powder used in the test are 3ml: 0.2g by volume and mass ratio. Mix the epoxy curing agent solution w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com