Sample cup and multi-channel optical test system containing same

A sample cup and sample technology, applied in the field of sample cups, can solve the problems of low heat conduction efficiency, cumbersome procedures, and affecting the accuracy of experimental results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

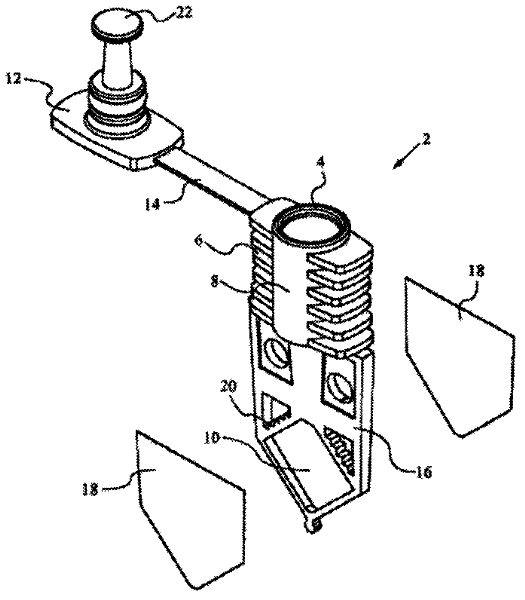

[0030] Referring to FIGS. 4-8 , the sample cup of the present invention includes a sealing cover 1 , a flexible connecting plate 2 , a cup body 12 and a sample cavity patch 11 . When the sample cup is working, the sample stored in the sample chamber 7 of the sample cup will experience a continuous heating process, and the pressure in the cup will constantly change alternately, and the sealing cover 1 is made of flexible material. When the pressure in the cup increases When it is large, the flexible sealing cover 1 can be deformed and expanded, so as to avoid inaccurate measurement results caused by overflow of samples.

[0031] The flexible connecting plate 2 connects the sealing cover 1 and the cup body 12 together, so that the sealing cover 1 will not break away from the cup body 12, avoiding confusion between the sealing covers of multiple sample cups, thereby avoiding confusion due to the sealing cover 1 resulting in cross-contamination of samples.

[0032] The cup body 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com