Method for evaluating bonding strength of mechanical composite tube

A technology that combines strength and evaluation methods. It is applied in the direction of strength characteristics, using repeated force/pulsation force to test material strength, and using stable tension/pressure to test material strength. It can solve the problems of inability to detect online, large detection errors, and damage In order to reduce the cost of inspection, the detection error is small, and the results are reliable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The method for evaluating the bonding strength of mechanical composite pipes includes the following steps:

[0046] Step 1. Select the standard mechanical composite pipe whose bonding strength meets the evaluation requirements and has the same material and specifications as the mechanical composite pipe to be tested, that is, the selected standard mechanical composite pipe to be tested. Equal wall thickness and equal length.

[0047] The specific selection method of the standard mechanical composite pipe is as follows:

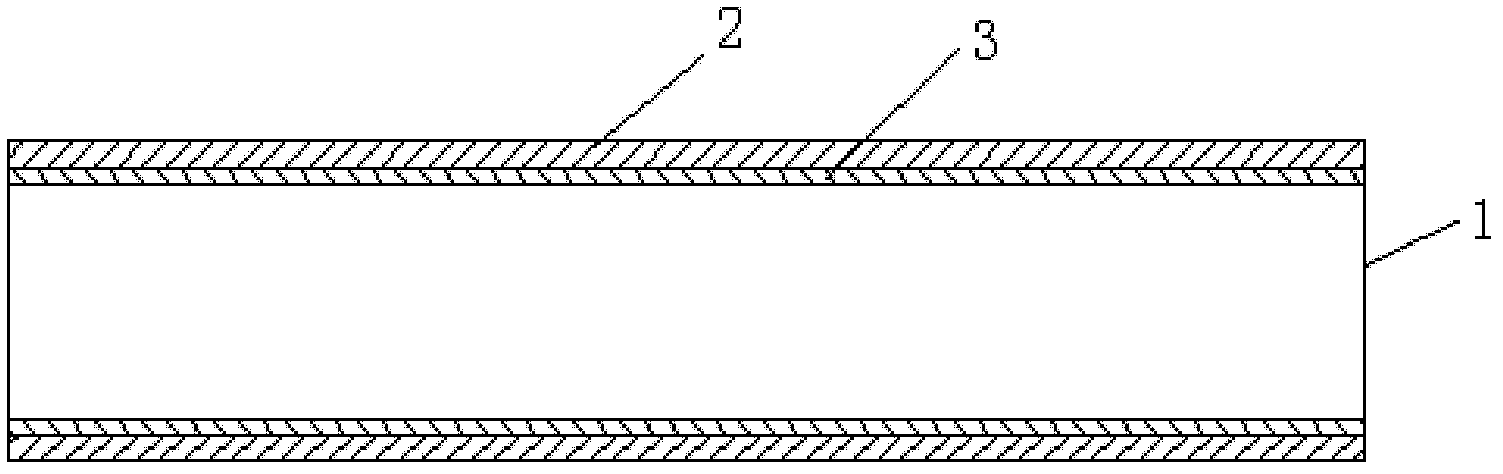

[0048] Step 1.1, assemble the base pipe and liner coaxially with the material, outer diameter, wall thickness and length of the composite pipe to be tested to obtain the mechanical composite pipe before standardization;

[0049] Step 1.2, standardization processing

[0050] Step 1.2.1, initial loading

[0051] Install sealing devices at both ends of the composite pipe obtained in step 1.1, and attach axial strain gauges and hoop strain gauges at the ...

Embodiment 2

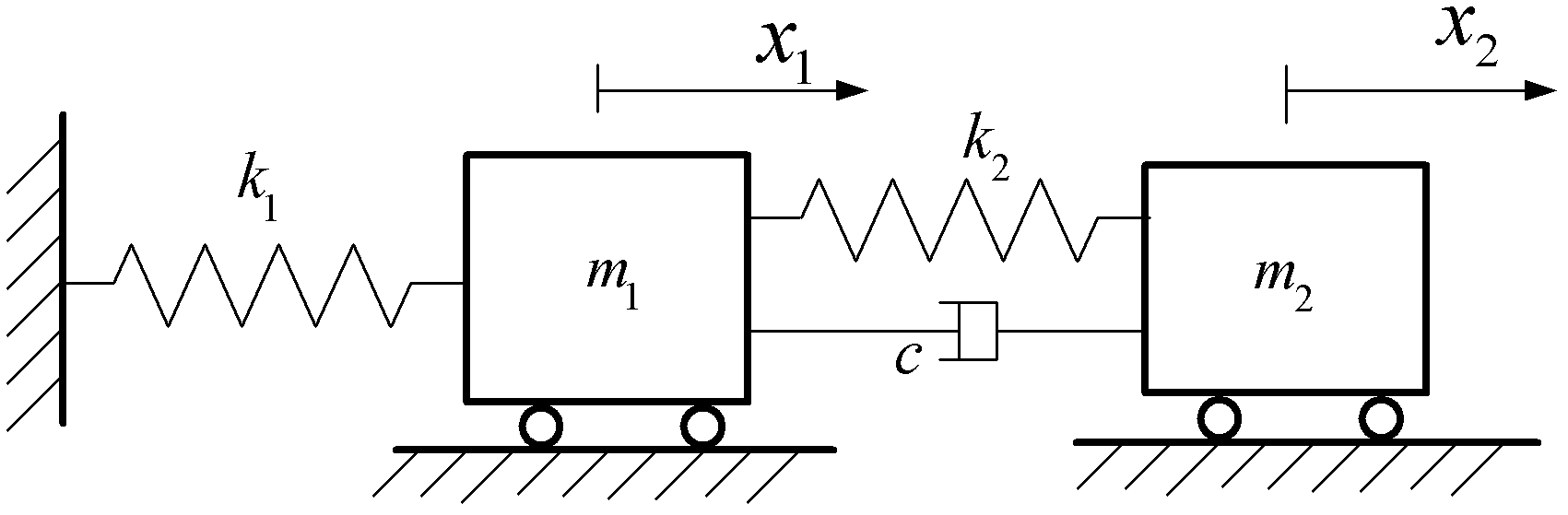

[0069] In this embodiment, the modal parameter used to detect and evaluate the bonding strength of the composite pipe is damping ξ. In step 2, after analyzing the frequency response of the acceleration signal and the force signal, the damping ξ of the standard mechanical composite tube is obtained 标准 . In step 3, after performing frequency response analysis on the acceleration signal and force signal of the mechanical composite pipe to be tested, the damping ξ of the mechanical composite pipe to be tested is obtained 待测 , other step methods of step 1 to step 3 are all the same as in embodiment 1.

[0070] In step 4, compare the damping ξ of the mechanical composite tube to be tested obtained in step 3 with the damping ξ of the standard mechanical composite tube obtained in step 2 标准 For comparison, when ξ 待测 ≤ξ 标准 , the bonding strength of the mechanical composite pipe to be tested is qualified, otherwise, the bonding strength of the mechanical composite pipe to be tested ...

Embodiment 3

[0103] In this embodiment, the modal parameter used to detect and evaluate the bonding strength of the composite pipe is the transmissibility η. The step method of step 1 is identical with embodiment 1.

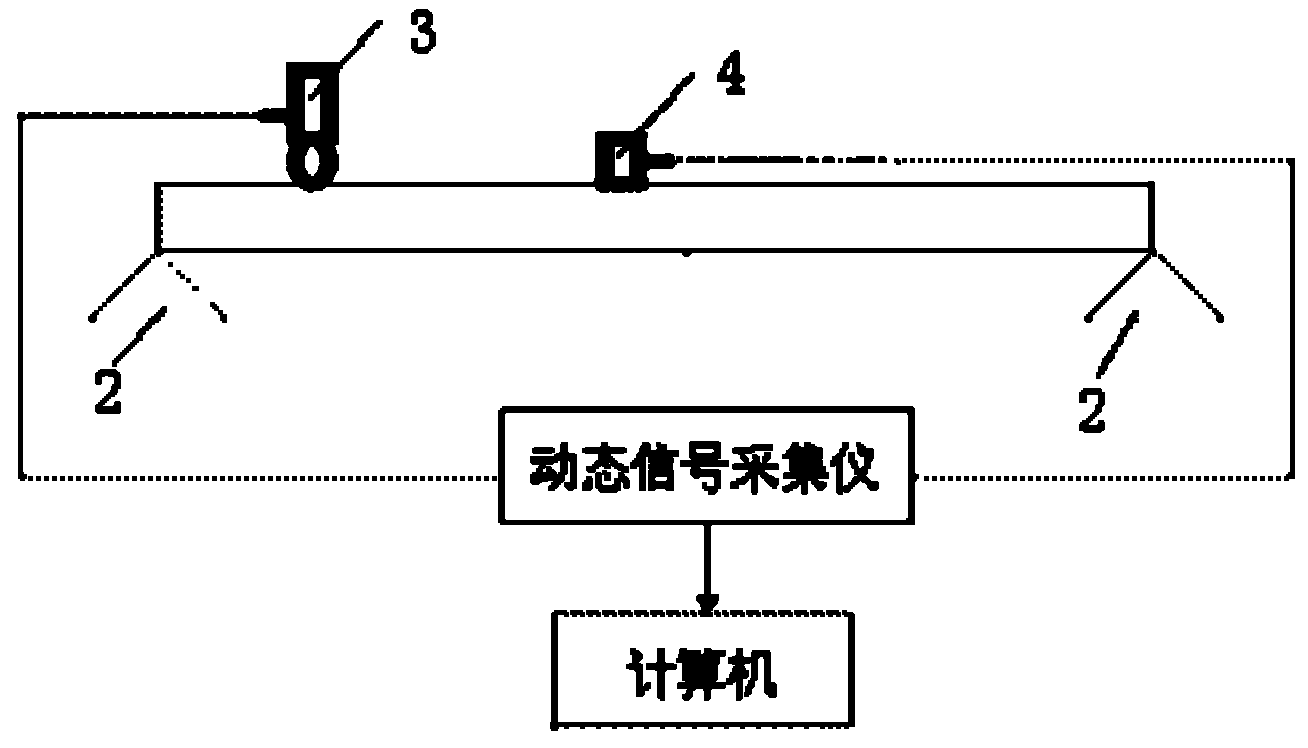

[0104] Step 2. Apply excitation to the mechanical composite pipe of the standard part obtained in step 1 in a certain way, record the excitation force signal, collect the acceleration signal of a specific point of the mechanical composite pipe of the standard part in real time, analyze and process the obtained signal, and obtain the standard Transmissibility η of a piece of mechanical composite pipe 标准 .

[0105] The specific method of step 2 is: place the standard mechanical composite pipe with a length of 1 obtained in step 1 horizontally on two V-shaped grooves, adjust the positions of the two V-shaped grooves so that the two V-shaped grooves support parts The outer end faces are vertically aligned with the two outer end faces of the composite pipe.

[0106] Arrange No....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com