Diffusion process for crystalline silicon solar cell

A solar cell and diffusion process technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of long single-tube process time, poor single-chip uniformity, sheet resistance deviation, etc., to help photoelectric conversion efficiency, improve yield, The effect of diffusion uniformity help

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The diffusion process of the crystalline silicon solar cell of the present invention is on the basis of keeping other original processes unchanged. The diffusion furnace can be selected from the tube type diffusion furnace of the 48th Research Institute of China Electronics Technology Group Corporation. The format of the process parameters we edit is also according to this Diffusion Furnace Format.

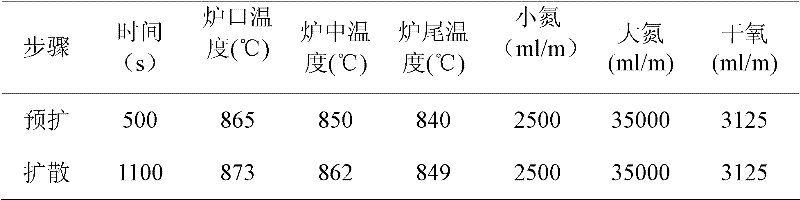

[0030] Table 4 is the process parameter before pre-expansion

[0031]

[0032] Because a large amount of cold air will be brought into the tube when entering the boat, especially the temperature at the furnace mouth will drop quickly, and it will take a long time to maintain the temperature when it rises to the specified temperature, which will affect the production capacity per unit time, so the present invention will make further progress The temperature at the furnace mouth and in the furnace was increased by 10°C and 5°C respectively, and the constant temperature tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com