A Diffusion Process That Improves the Minority Carrier Lifetime of Metallurgical-Grade Silicon Wafers

A diffusion process and minority carrier lifetime technology, applied in the field of diffusion process, can solve the problems of not forming a physical metallurgical grade silicon diffusion process, increasing the recombination probability of photogenerated carriers, and failing to improve the product yield, etc., so as to improve the surface passivation effect, Improve conversion efficiency and yield, and save phosphorus sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

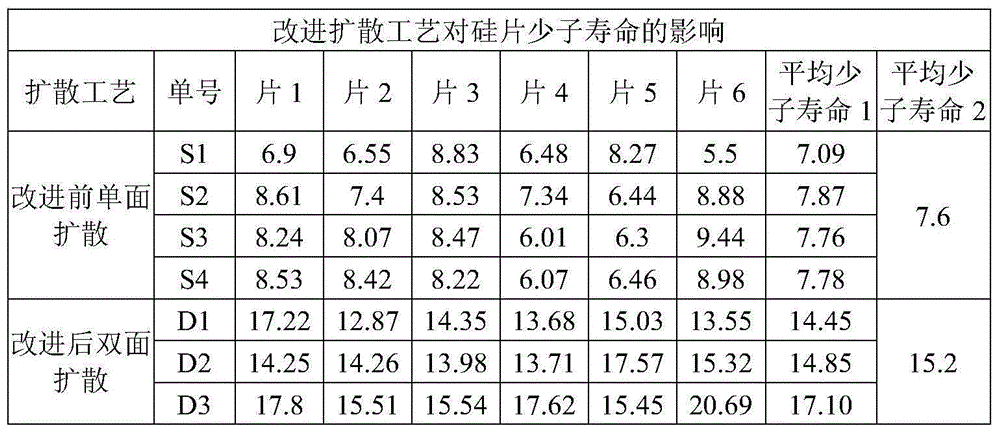

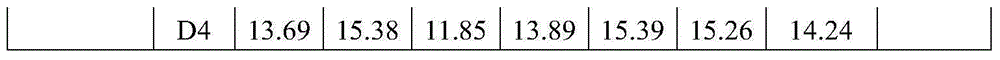

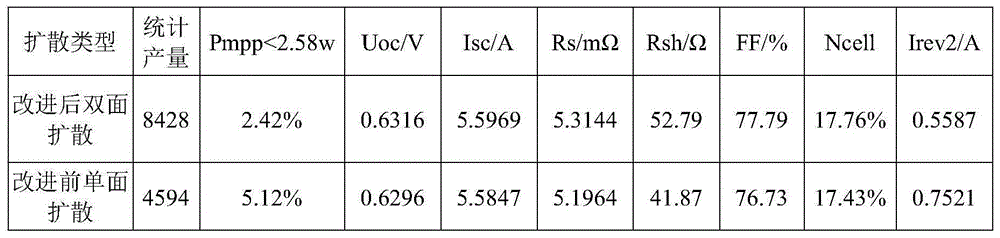

Examples

Embodiment 1

[0024] A diffusion process capable of improving the minority carrier lifetime of metallurgical-grade silicon wafers, comprising the following steps:

[0025] (1) Low-temperature boat feeding and initial heating: when the initial temperature is 810°C, start to push the quartz boat carrying silicon wafers into the furnace tube, and keep the speed of 400mm / min to fully load the quartz boat with silicon wafers (each slot of the quartz boat Only one piece of silicon wafer (to achieve double-sided diffusion) is sent into the furnace tube. After the furnace door is closed, the temperature is raised to 840°C within 600s according to the diffusion heating capacity, and then kept at this temperature for 600s with oxygen.

[0026] (2) Simultaneous temperature rise and source diffusion: After the heat preservation is at 840°C, phosphorus oxychloride is introduced to carry out phosphorus diffusion, and the temperature is raised by 9°C in three steps during this process. The total power-on ...

Embodiment 2

[0031] (1) Low-temperature boat feeding and initial temperature rise: When the initial temperature is 820°C, start to push the quartz boat carrying silicon wafers into the furnace tube, control the boat feeding speed to 500mm / min, and raise the temperature to 830°C after the boat feeding is completed and Keep warm for 7 minutes in an atmosphere where nitrogen and oxygen coexist, and the flow rates of oxygen and nitrogen are controlled at 1200mL / min and 23000mL / min respectively; each slot of the quartz boat has only one silicon wafer, so as to realize double-sided diffusion;

[0032] (2) Source diffusion: After the heat preservation process, nitrogen carries liquid phosphorus oxychloride into the furnace tube, and reacts with oxygen and silicon surface under nitrogen atmosphere to form phosphorus atoms that diffuse into the silicon wafer for source diffusion;

[0033]The source diffusion is completed in three steps. In the three steps, the flow rates of nitrogen, oxygen, and lar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com