Self-heating floor and electrothermal component thereof

An electric heating and component technology, applied in the field of architectural decoration, can solve the problems of damaged electric heating wires, failure to implement, and potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

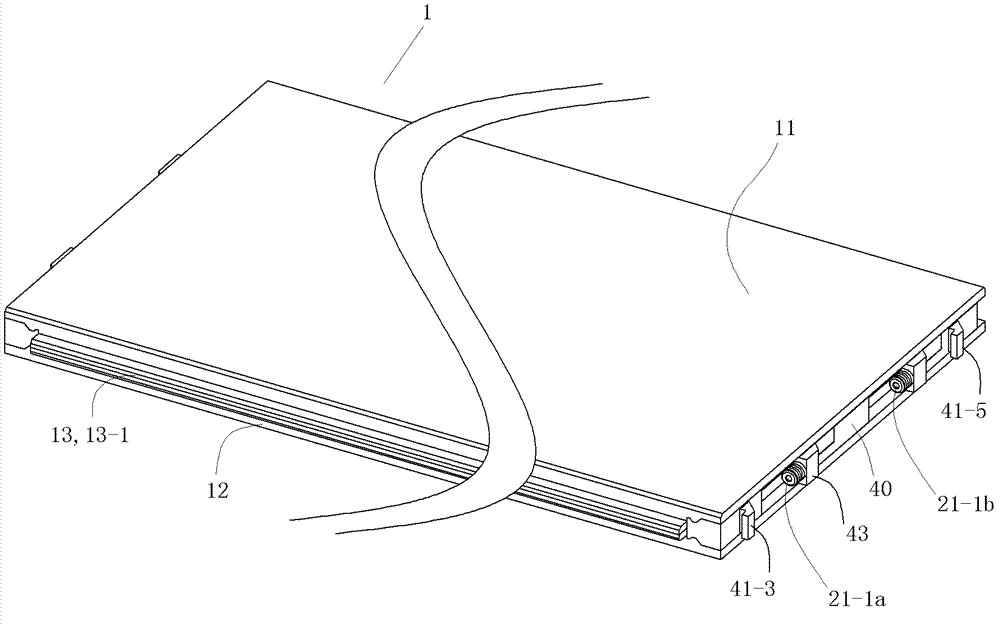

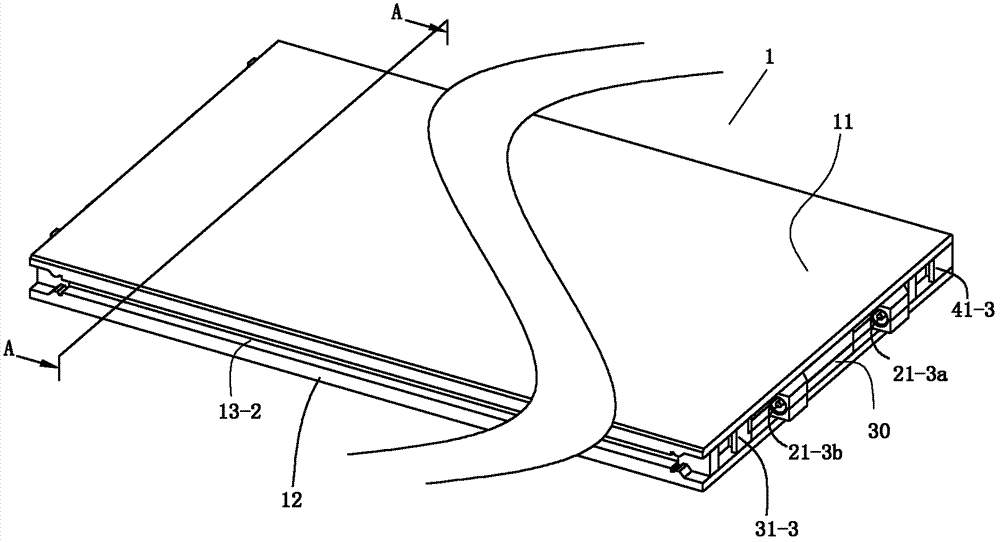

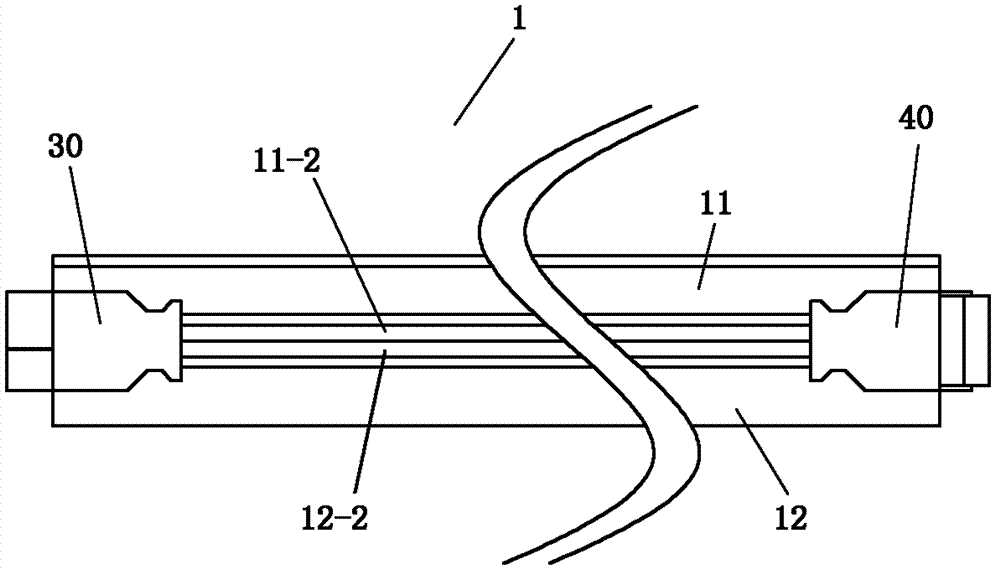

[0300] (Example 1, electrothermal component)

[0301] See Figure 9 , Figure 10 , Figure 17 , Figure 23 and Figure 30 , the electrothermal assembly 200 of this embodiment is a waterproof electric heating assembly, and the electrothermal assembly 200 can be used as a part of the self-heating floor or independently. The electrothermal component 200 includes a circuit device 20 , a first mounting base 30 and a second mounting base 40 . The first mounting seat 30 is a part that is plugged and electrically connected to each other by its socket part and the plug part of the second mounting seat 40 of the adjacent electrothermal component 200 when in use; the second mounting seat 40 is a part that is electrically connected by its plug The part is a component that is hermetically plugged and electrically connected to the socket part of the first mounting base 30 of the adjacent electrothermal component 200 .

[0302] See Figure 10 to Figure 12 , the circuit device 20 inclu...

Embodiment 2

[0384] (Example 2, electrothermal component)

[0385] The rest of this embodiment is the same as Embodiment 1, except that the cover plate 32 of the first mount 30 is not provided with the glue injection hole 32-2 and the exhaust hole 32-3, so the main body of the first mount 30 There is no need to inject insulating glue into the cavity.

[0386] The two cover plates 42 of the second mounting base 40 are not provided with the glue injection hole 42-2 and the exhaust hole 42-3, so the corresponding space formed by each cover plate 42 and the second seat body 41 does not need to inject insulation. glue.

Embodiment 3

[0387] (Example 3, electrothermal component)

[0388] See Figure 31 and Figure 32 , the rest of this embodiment is the same as that of Embodiment 1, the difference is that: the insertion hole 30-2 in the front socket 30-3 of the first mounting seat 30 of the electrothermal component 200 and the insertion hole 30-2 in the rear socket 30-5 The insertion holes 30-4 in the socket are arranged in the same direction along the axis of the left and right direction; the two plugs 43 of the second mounting base 40 are also arranged in the same direction along the axis of the left and right direction.

[0389] The front buckle part 31-3 and the rear buckle part 31-5 of the first seat body 31 of the first mounting seat 30 are both the parts of the "L"-shaped hole in section, and the "L"-shaped One opening of the hole is to the left, and the other opening is upward; the front buckle part 41-3 and the rear buckle part 41-5 of the second seat body 41 of the second mounting seat 40 are c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com