Active type integrating device of micro-pore monitoring and seam tracking in short-wavelength laser welding

A technology of laser welding and integrated device, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of complicated installation, inconvenient installation, complicated equipment, etc., and achieve the effect of easy operation, convenient installation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

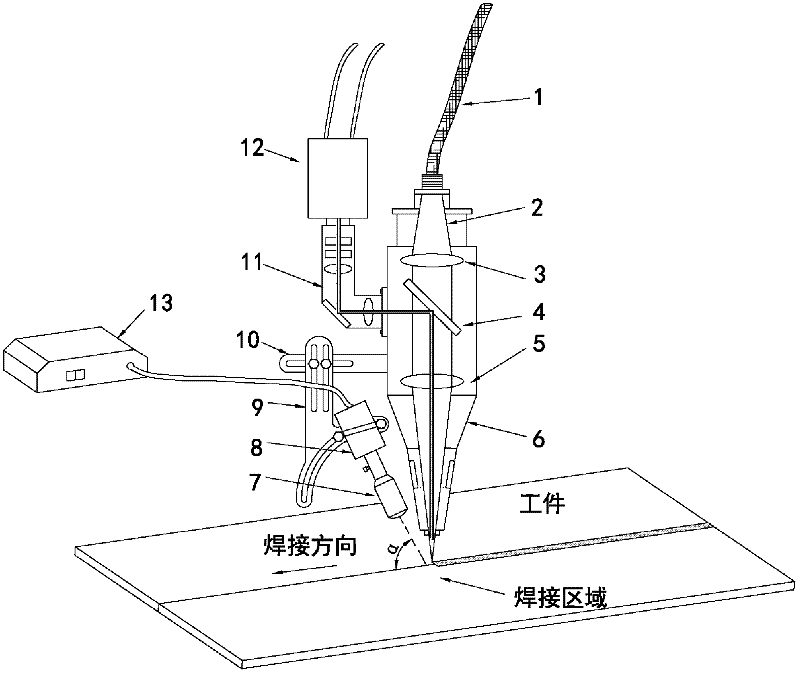

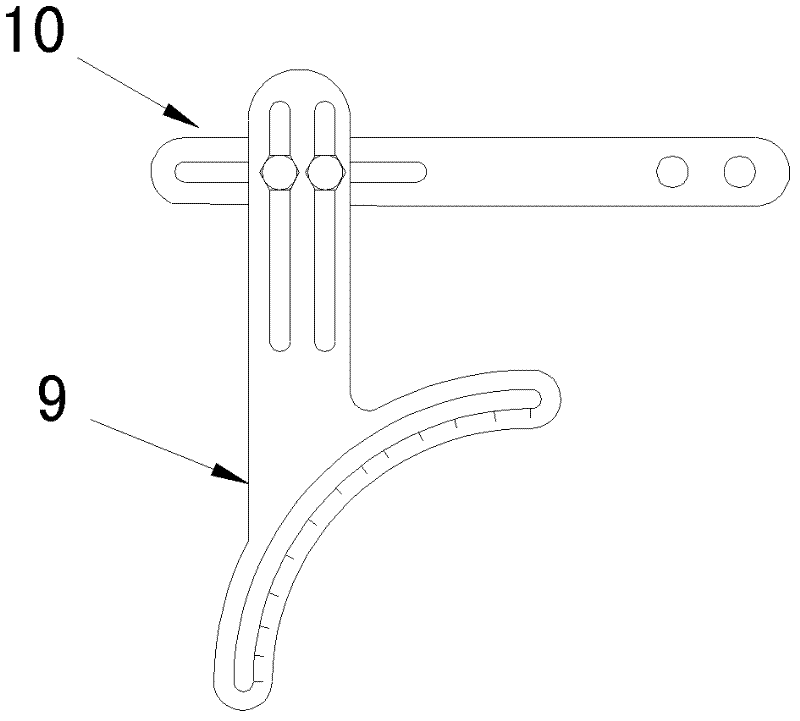

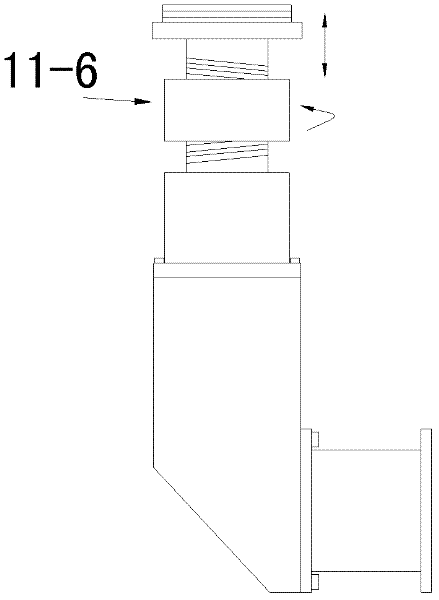

[0042] An active short-wavelength laser welding small hole monitoring and weld seam tracking integrated device, such as figure 1 As shown, firstly, the lens C11-1, the mirror 11-2, the lens D11-3, the filter 11-4, and the dimmer 11-5 are arranged according to Figure 4 The optical path layout is installed in the coaxial lens, and the CCD or CMOS camera 12 is connected to the coaxial lens through the C-type interface and installed on the side of the laser head 6 through the set screw; the point light source fixing bracket 10 is installed on the side of the laser head through the set screw On one side of the laser head 6, set the condenser 7 on the head of the point light source 8 and install it on the point light source adjustment bracket 9 through manual screws, and the point light source adjustment bracket 9 is connected with the point light source fixing bracket 10 through manual bolts; Before the point light source controller 13 is used to make the output brightness of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com