Natural fiber composite health-care cushion and preparation method thereof

A technology of natural fibers and health care pads, applied in the field of composite pads, can solve the problems of not taking into account the air permeability of low-melting fibers, unable to prevent hard fibers from plucking out, and uncomfortable for users, achieving good moisture absorption and air permeability and saving transportation. Cost, ease of handling and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

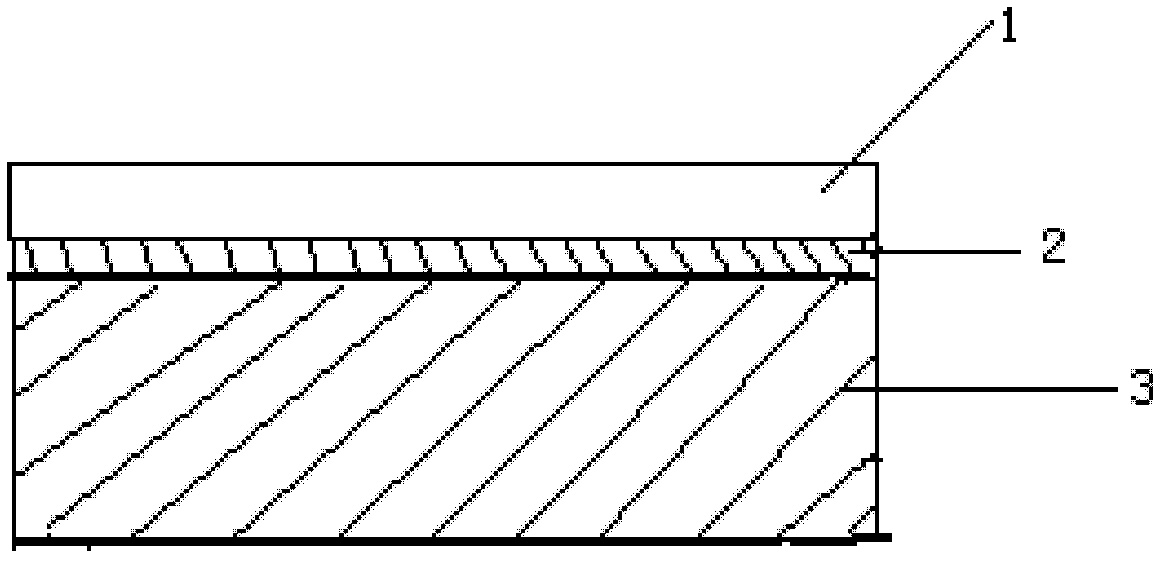

[0043] In the first step, each component is weighed according to the required ratio, opened and mixed, pre-laid, carded, air-laid, and needle-punched to prepare the non-woven layer of the upper surface layer 1 and the first barrier layer 2, respectively. Wherein the non-woven layer of the upper surface layer 1 adopts 10% PP fiber and 90% elastic chemical fiber, and the non-woven layer of the first barrier layer 2 adopts 100% flax fiber; the needle cloth needle density in the acupuncture process is 1000 pieces / m, the acupuncture frequency is 1500 times / min, and the speed is 2m / min;

[0044] The second step: according to the ratio of 20% ES fiber, 70% flax fiber, and 10% bamboo charcoal fiber, carry out weighing, opening and mixing, pre-forming, carding, and air-laid to make the middle layer 3, wherein the pre-formed The speed of netting, carding and air-laid process is 5m / min;

[0045] The third step: the two-layer non-woven layer prepared by step S01 and the middle layer 3 p...

Embodiment 2

[0049] In the first step, each component is weighed according to the required ratio, opened and mixed, pre-laid, carded, air-laid, and needle-punched to prepare the non-woven layer of the upper surface layer 1 and the first barrier layer 2, respectively. Wherein the non-woven layer of upper surface layer 1 adopts 40% PE / PET core fiber, 60% jute fiber, and the non-woven layer of the first barrier layer 2 adopts 20% jute fiber and 80% kenaf fiber; The needle board needle density is 3000 pieces / m, the needling frequency is 1000 times / min, and the speed is 10 m / min;

[0050] The second step: according to the ratio of 30% ES fiber, 20% jute fiber, and 50% coconut palm fiber, weighing, opening and mixing, pre-forming, carding, and air-laid to make the middle layer 3, wherein the pre-formed The speed of netting, carding and air-laid process is 10m / min;

[0051] The third step: the two-layer non-woven layer prepared by step S01 and the middle layer 3 prepared by step S02 according to...

Embodiment 3

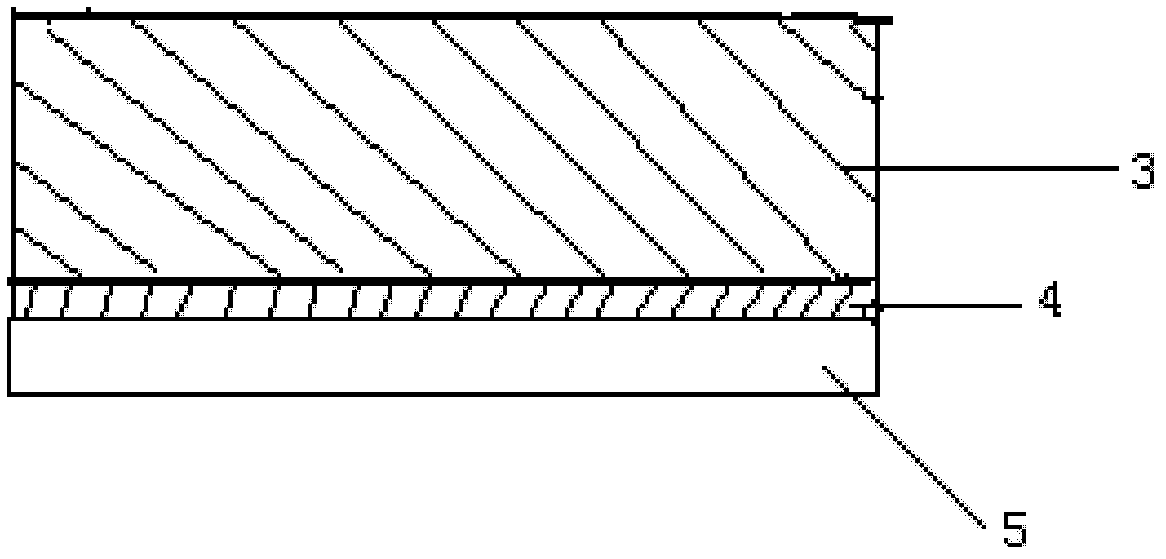

[0055] In the first step, each component is weighed according to the required ratio, opened and mixed, pre-laid, carded, air-laid, and needle-punched to prepare the non-woven layer of the lower surface layer 5 and the second barrier layer 4, respectively. Wherein the non-woven layer of the lower surface layer 5 adopts 25% 4080 fibers, 45% elastic chemical fibers, and 30% kenaf fibers, and the non-woven layer of the second barrier layer 4 adopts 70% kenaf fibers and 30% polyester fibers. The density of the needle board needles in the needling process is 5000 pieces / m, the needling frequency is 100 times / min, and the speed is 18 m / min;

[0056] Step 2: According to the ratio of 40% PE / PET sheath-core fiber, 50% sisal fiber, and 10% palm fiber, carry out weighing, opening and mixing, pre-forming, carding, and air-laying to make the middle layer 3 , wherein the speed of pre-forming, carding and air-forming process is 18m / min;

[0057] The third step: the two-layer non-woven layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com