Device and method for realizing thermal-hydrolysis fermentation treatment in rotation way

A rotary method and thermal hydrolysis technology, applied in the field of thermal hydrolysis, can solve the problems of high energy consumption, long thermal hydrolysis cycle, low heat exchange efficiency, etc., and achieve the effect of high heat exchange efficiency and short thermal hydrolysis cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

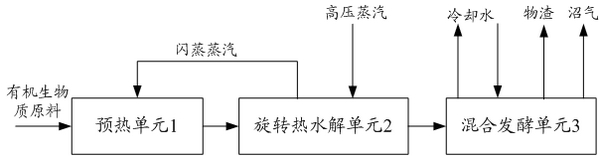

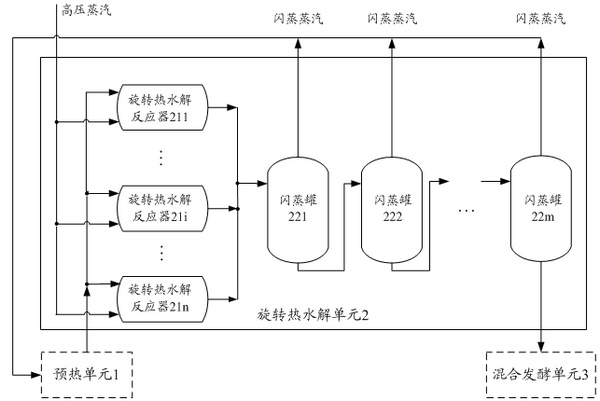

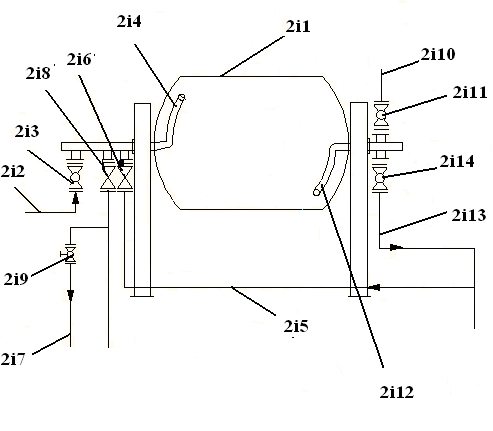

[0053] Figure 7 It is a schematic diagram of the composition and structure of an embodiment of the device and method for implementing thermal hydrolysis fermentation treatment by means of rotation in the present invention. like Figure 7 As shown, the device described in this embodiment that adopts a rotary method to realize thermal hydrolysis fermentation treatment includes a preheating tank, a rotary thermal hydrolysis reactor a, a rotary thermal hydrolysis reactor b, a flash tank, a heat exchanger and A digester. The organic biomass raw material in this embodiment is sludge, for example, municipal sludge. The method of implementing thermal hydrolysis and fermentation in this embodiment is as described above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com