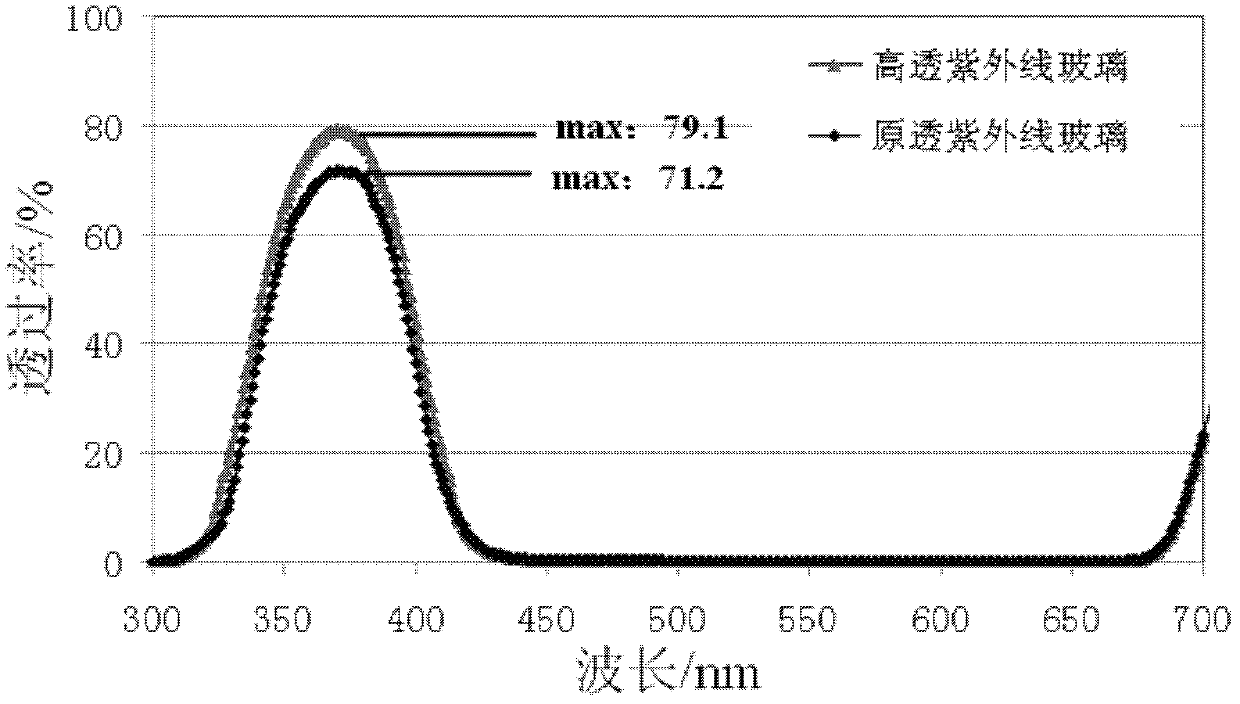

Glass with high transmissivity of ultraviolet A and preparation method for same

A long-wave ultraviolet and glass technology, which is applied in the field of high-transmittance long-wave ultraviolet glass and its preparation, can solve the problems of non-compliance with use requirements, low transmittance, and high visible light transmittance requirements, and achieves high yield and low melting point. , the effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

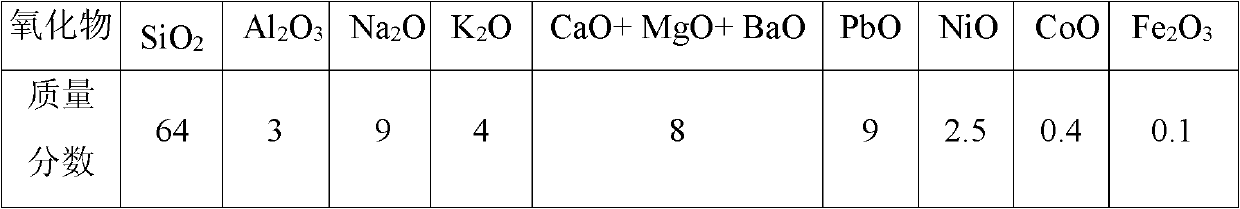

Embodiment 1

[0026] formula:

[0027]

[0028] The glass batch prepared according to the above formula was melted at 1450°C for 7.5 hours, and a high-transmission long-wave ultraviolet glass tube was prepared by using the horizontal tube drawing technology. The softening point temperature of this glass tube was 622°C.

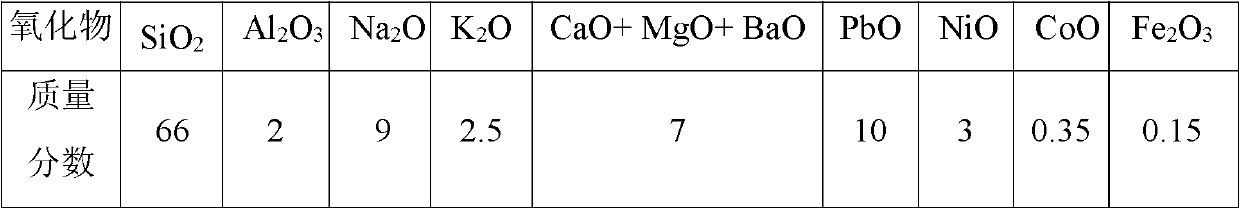

Embodiment 2

[0030] formula:

[0031]

[0032] The glass batch prepared according to the above formula was melted at 1470°C for 8 hours, and a high-transmission long-wave ultraviolet glass tube was prepared by vertical tube drawing technology. The softening point temperature of this glass tube was 613°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com