Method for utilizing semidry desulfurization waste residues to prepare masonry cement

A semi-dry method of desulfurization and masonry cement technology, which is applied in the direction of cement production, etc., can solve the problems of low dosage, unfavorable treatment and utilization of desulfurization ash in large quantities, low early strength, etc., and achieve large dosage, rapid and effective treatment and utilization , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

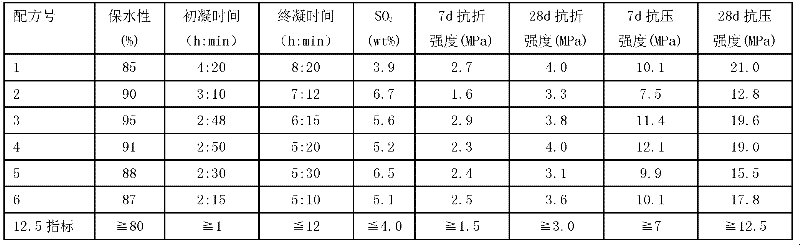

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with specific experimental examples.

[0018] (1) Dry the blast furnace slag at first, and the water content of the dried blast furnace slag is 0.8%. Grind the dried blast furnace slag finely, its particle size is 80μm square hole sieve is 5% of the total mass, Blaine specific surface area is 490m 2 / kg. Thereby obtaining blast furnace slag powder meeting the requirements.

[0019] (2) The water content of the semi-dry desulfurization slag is detected, and the content of adsorbed water is 0.7%; the desulfurization slag is off-white to light gray-yellow fine powder, with good dispersibility and fluidity, and an average particle size of 4-10um. BET specific surface area is 2-10m 2 / g, its composition is: the mass percent content is the CaO of 40-50%, the SO of 8-16% 3 , 10-18% SO 2 , 1-3% MgO, 1-2% TFe, 0.2-1.0% SiO 2 , 0.4-0.6% Al 2 o 3 , 1-5% K 2 O, 0.1-0.5% Na 2 O, 1-5% chloride, 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com