Improved polypropylene and method for improving yield strength and toughness of polypropylene

A technology of polypropylene and isotactic polypropylene, which is applied in the field of polypropylene materials, can solve problems such as important influences that cannot be questioned, and achieve the effect of improving yield toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

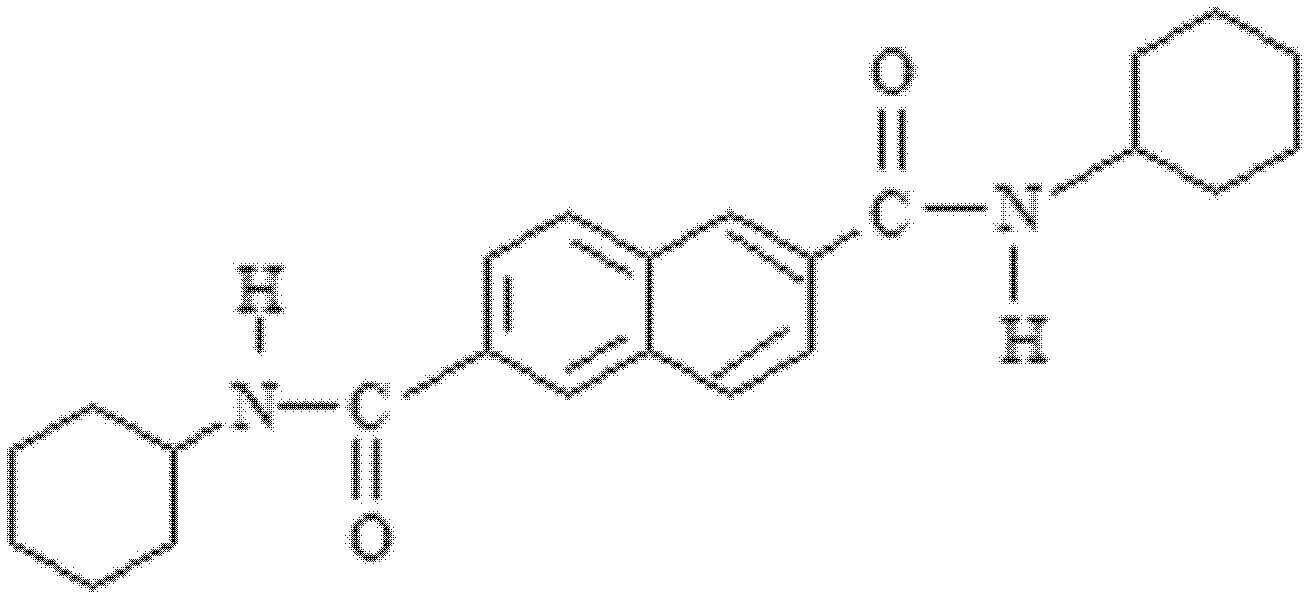

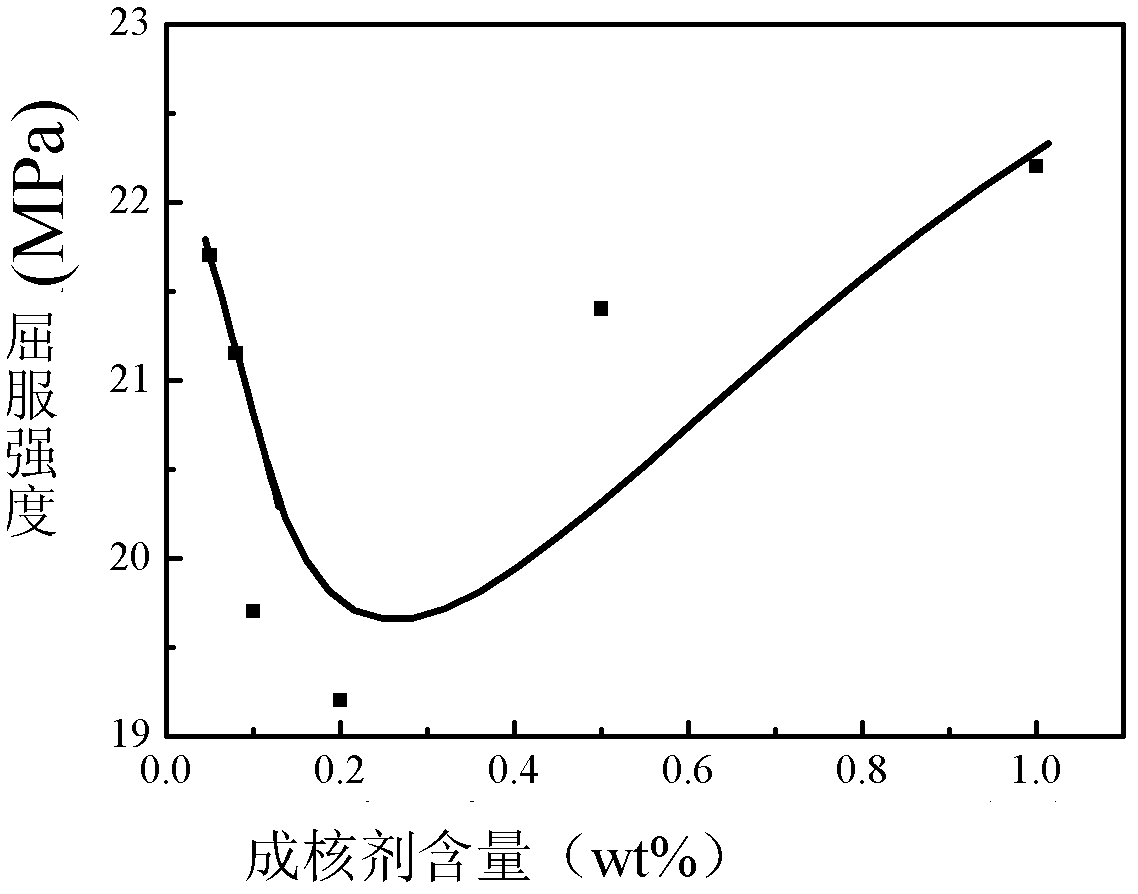

[0017] Take by weighing one hundred kilograms of isotactic polypropylene (brand T1701, Sinopec Beijing Yanshan Petrochemical Company), take by weighing DCNDCA nucleating agent 50g according to the amount of its mass percentage 0.05%, the polypropylene that takes by weighing and DCNDCA nucleating agent are at room temperature After being mixed evenly at high speed, it is sent to the feeding hopper of the twin-screw extrusion granulation unit. The temperature of the mixing section of the unit is set at 210 degrees Celsius, and the temperature of the machine head is set at 190 degrees Celsius. Polypropylene pellets containing 0.05% by mass of DCNDCA nucleating agent were obtained. The pellets were melted and then extruded into pipes. The crystallization temperature was controlled at 135° C., and the yield strength was 21.4 MPa when tested under tension.

Embodiment 2

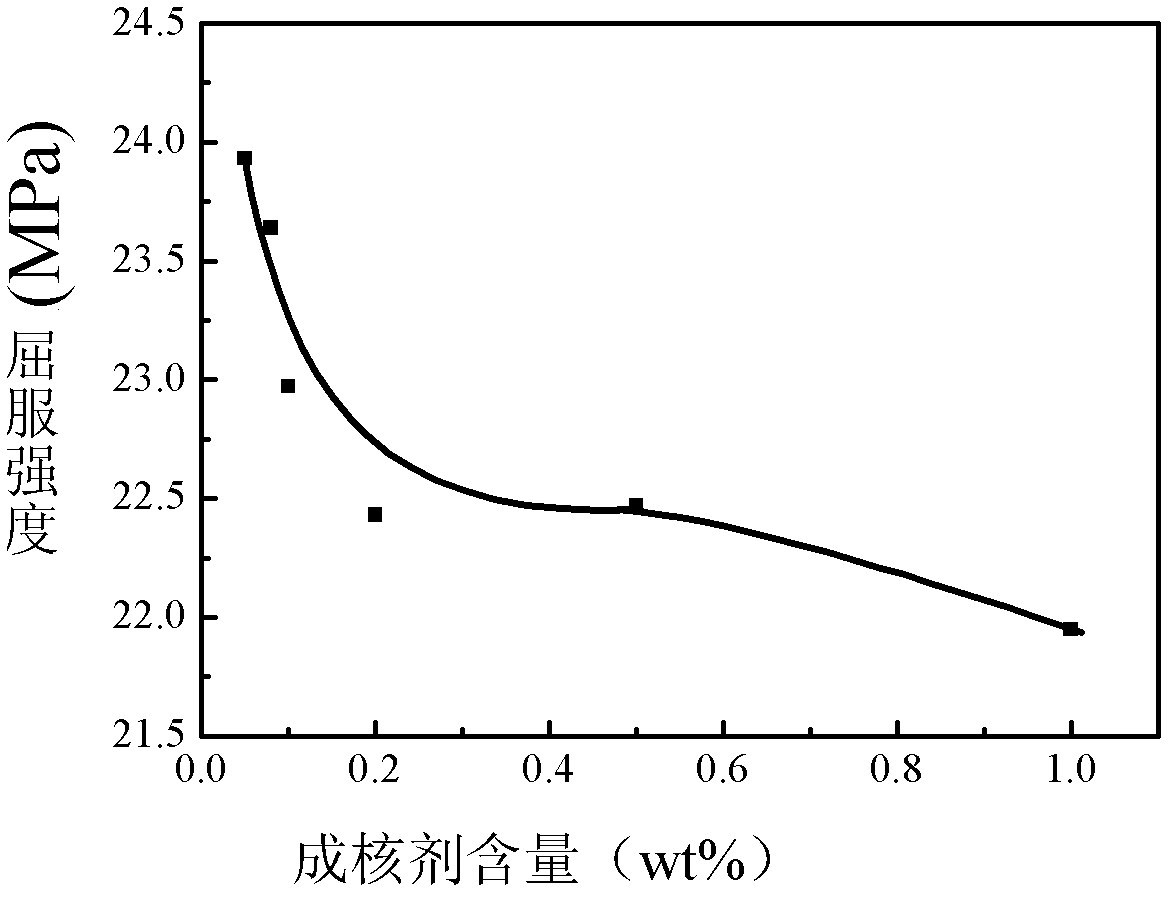

[0019] Take by weighing one hundred kilograms of isotactic polypropylene (brand T1701, Sinopec Beijing Yanshan Petrochemical Company), take by weighing DCNDCA nucleating agent 50g according to the amount of its mass percentage 0.05%, the polypropylene that takes by weighing and DCNDCA nucleating agent are at room temperature After being mixed evenly at high speed, it is sent to the feeding hopper of the twin-screw extrusion granulation unit. The temperature of the mixing section of the unit is set at 210 degrees Celsius, and the temperature of the machine head is set at 190 degrees Celsius. Polypropylene pellets containing 0.05% by mass of DCNDCA nucleating agent were obtained. The pellets were melted and then extruded into pipes. The crystallization temperature was controlled at 140° C., and the yield strength was 23.9 MPa when tested under tension.

Embodiment 3

[0021] Take by weighing one hundred kilograms of isotactic polypropylene (brand T1701, Sinopec Beijing Yanshan Petrochemical Company), take by weighing DCNDCA nucleating agent 200g according to the amount of its mass percentage 0.2%, the polypropylene that takes by weighing and DCNDCA nucleating agent are at room temperature After being mixed evenly at high speed, it is sent to the feeding hopper of the twin-screw extrusion granulation unit. The temperature of the mixing section of the unit is set at 210 degrees Celsius, and the temperature of the machine head is set at 190 degrees Celsius. Polypropylene granules containing 0.2% by mass of DCNDCA nucleating agent were obtained, and the granules were melted and then injection-molded into thin sheets. The temperature of the mold was controlled at room temperature 135° C., and the yield strength was 19.3 MPa when tested under tension.

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com