Preparation method of color master batch titanium dioxide

A technology of titanium dioxide and color masterbatch, applied in chemical instruments and methods, dyeing physical treatment, dyeing organic silicon compound treatment, etc., to achieve high application performance and good covering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

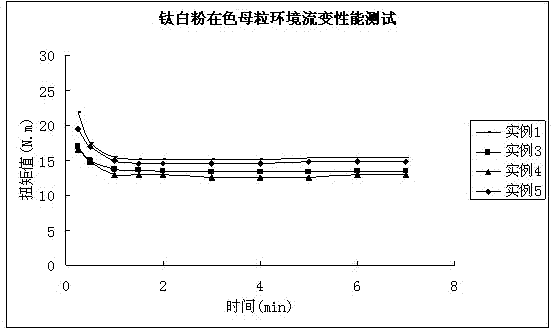

Image

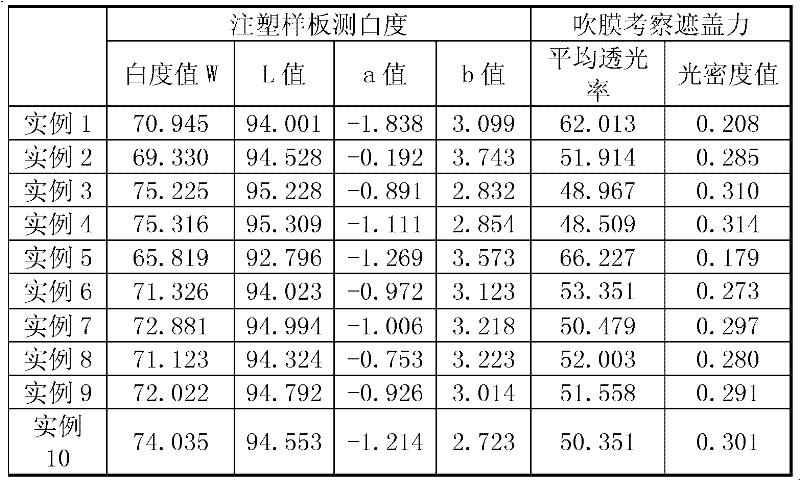

Examples

example 1

[0016] Use sulfuric acid rutile titanium dioxide without surface treatment, add deionized water to make a slurry with a concentration of about 700g / l, add 0.2-0.3% sodium silicate, and disperse by sand milling at 2000rpm for 60 minutes. Add a certain amount of deionized water to the dispersed slurry and dilute it to 300g / l, and pass the slurry through a 300-mesh screen. The temperature of the slurry was raised to 65°C, and sodium metaaluminate solution and sulfuric acid solution were added simultaneously at pH 8.5 for 60 minutes, and the amount of sodium metaaluminate solution was 2% as Al2O3 (calculated based on TiO2 mass). The slurry was aged at pH 8.5 for 60 minutes at a temperature of 65°C to further age the inorganic-coated alumina hydrate film. After the aging is completed, sulfuric acid solution is added to adjust the final pH to 7.0. Finally, the inorganically treated slurry is washed with water and dried. In the jet crushing stage, an organic treatment agent is adde...

example 2

[0018] Use sulfuric acid rutile titanium dioxide without surface treatment, add deionized water to make a slurry with a concentration of about 700g / l, add 0.2-0.3% sodium silicate, and disperse by sand milling at 2000rpm for 60 minutes. Add a certain amount of deionized water to the dispersed slurry and dilute it to 300g / l, and pass the slurry through a 300-mesh screen. Raise the temperature of the slurry to 65°C, adjust the pH of the slurry to 5.5 with sulfuric acid solution, add aluminum sulfate solution and sodium hydroxide solution at the same time at this pH, the time is 60 minutes, and the amount of aluminum sulfate solution is 2% based on Al2O3 (Based on TiO2 mass calculation). The slurry was aged at pH 5.5 for 60 minutes at a temperature of 65° C. to further age the inorganic-coated alumina hydrate film. After the slaking is completed, sodium hydroxide solution is added to adjust the final pH to 7.5. Finally, the inorganically treated slurry is washed with water and ...

example 3

[0020] Use sulfuric acid rutile titanium dioxide without surface treatment, add deionized water to make a slurry with a concentration of about 700g / l, add 0.2-0.3% sodium silicate, and disperse by sand milling at 2000rpm for 60 minutes. Add a certain amount of deionized water to the dispersed slurry and dilute it to 300g / l, and pass the slurry through a 300-mesh screen. The temperature of the slurry was raised to 65°C, and sodium metaaluminate solution and sulfuric acid solution were added simultaneously at pH 8.5 for 60 minutes, and the amount of sodium metaaluminate solution was 1% based on Al2O3 (based on TiO2 mass calculation). The slurry was aged at pH 8.5 for 60 minutes at a temperature of 65°C to further age the inorganic-coated alumina hydrate film. After the aging is completed, sulfuric acid solution is added to adjust the final pH to 7.0. Finally, the inorganically treated slurry is washed with water and dried. In the jet crushing stage, an organic treatment agent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com