Lanthanide series compound thermo-chromatic material and preparation method thereof

A compound and thermal discoloration technology, which is applied in the direction of color-changing fluorescent materials, chemical instruments and methods, etc., can solve the problems of anti-ultraviolet, poor heat resistance and light resistance, affecting the color change of the compound, and phenolic color developer Toxic and other problems, to achieve the effect of reversibility, good color stability, sharp color change, and low color change temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

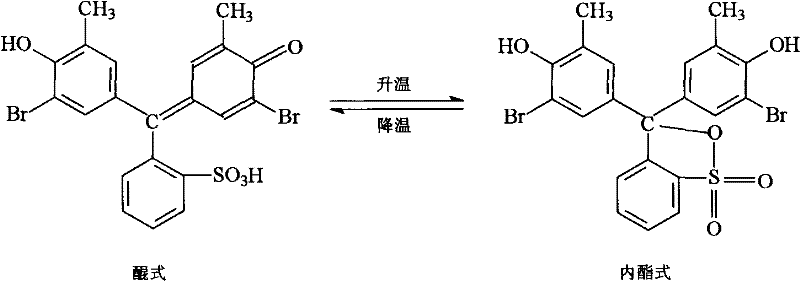

Method used

Image

Examples

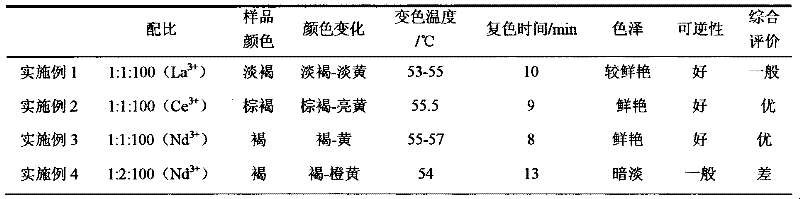

Embodiment 1

[0020] Weigh 30g of stearyl alcohol in a three-necked flask, heat and melt; weigh 0.3g of bromocresol violet and 0.3g of lanthanum nitrate, add them to the three-necked flask, stir fully to dissolve, and slowly raise the temperature to 130°C, constant temperature reaction 2.5 hour; cool the resulting product, wash twice with absolute ethanol and acetone, and filter under reduced pressure; dry at 35°C for 5 hours to obtain bromocresol purple-La 3+ - Octadecanol (mass ratio 1:1:100) thermochromic compound.

Embodiment 2

[0022] Replace lanthanum nitrate with cerium nitrate, and all the other steps are the same as in Example 1 to obtain bromocresol purple-Ce 3+ - Octadecanol (mass ratio 1:1:100) thermochromic compound.

Embodiment 3

[0024] Replace lanthanum nitrate with neodymium nitrate, and all the other steps are the same as in Example 1 to obtain bromocresol purple-Nd 3+ - Octadecanol (mass ratio 1:1:100) thermochromic compound.

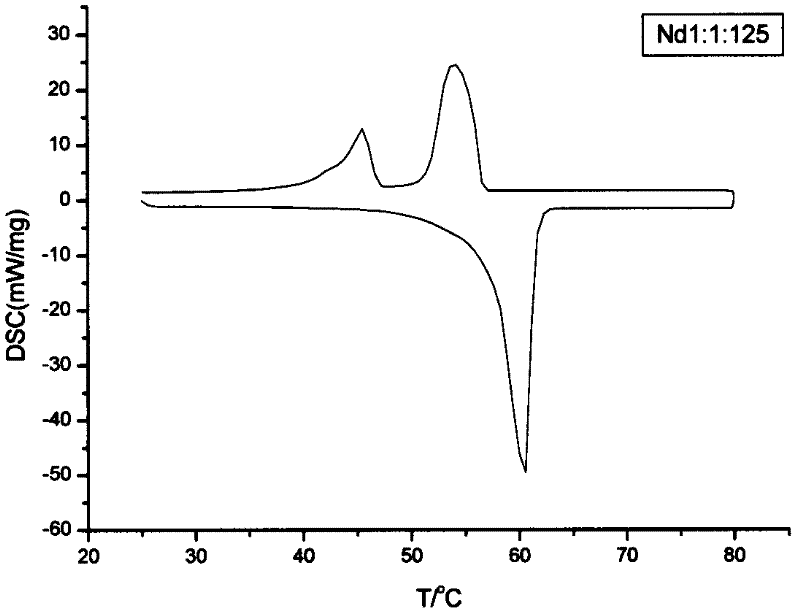

[0025] Carry out DSC analysis to it, as shown in the accompanying drawing. During the heating process, an obvious color-changing peak appeared at 60°C; during the cooling process, the sample began to condense at 54°C, and the obtained results were basically consistent with the data of the visual method. The endothermic enthalpy of heating up becomes 102.3J / g, and the exothermic enthalpy of cooling down becomes 101.7J / g, which further proves the reversibility of its discoloration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com