Clothes drying system and thread waste clearing method for same

A technology for drying clothes and lint, applied in the field of drying systems, which can solve problems such as increased temperature difference between the inlet and outlet of the drying cylinder, complex processing technology of the condenser, and unfavorable drying of clothes, so as to improve the efficiency of drying clothes and reduce the number of filters Effect of structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

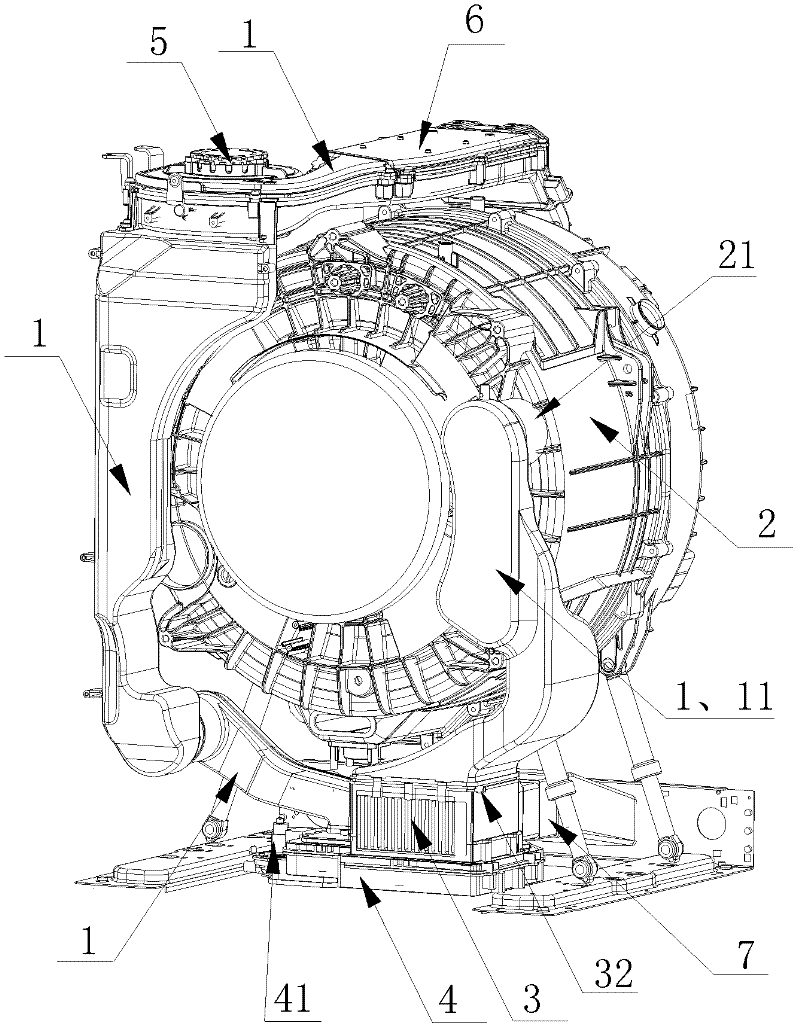

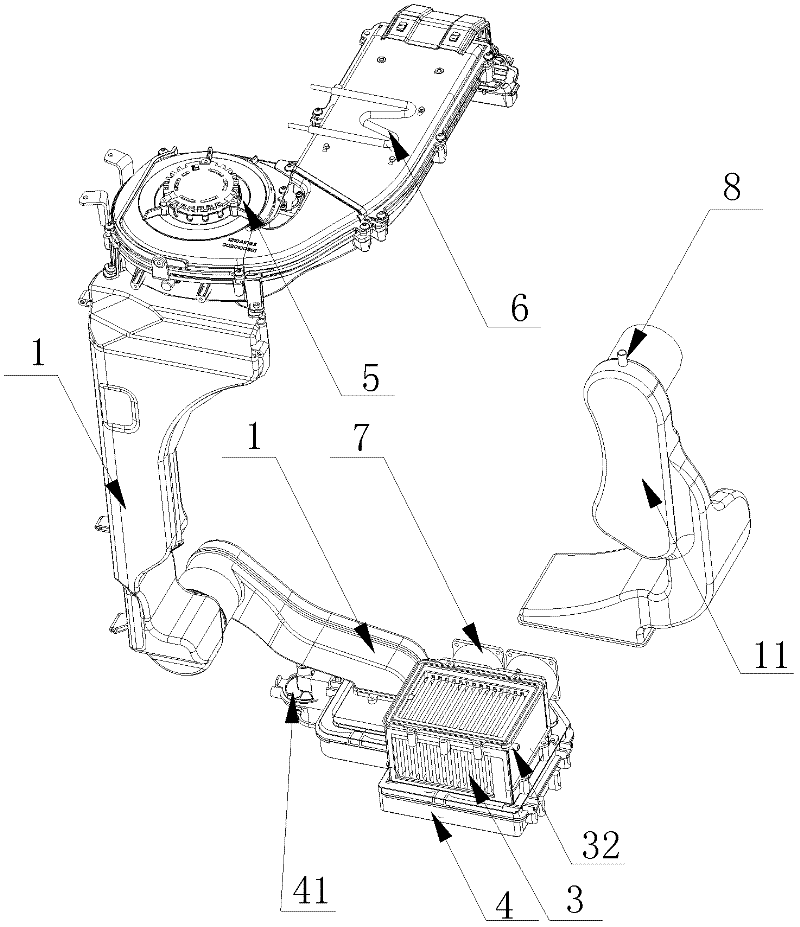

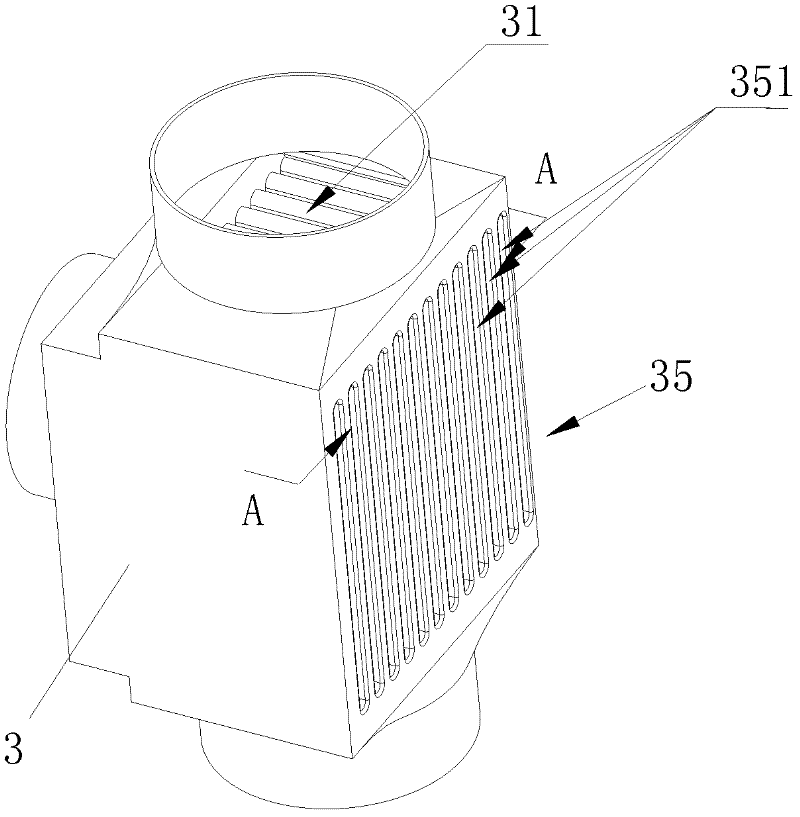

[0029] Such as Figure 1 to Figure 8 As shown, the drying system of the present invention mainly connects the air outlet 21 of the clothes bucket 2, the condenser 3, the water collection box 4, the drying fan 5, and the heater 6 to the clothes bucket by connecting the air duct 1 in sequence. The air inlet is connected, and the condenser 3 is provided with a mechanism for flushing and cleaning lint. The flushing cleaning lint mechanism is arranged at one end of the hot and humid air inlet 31 of the condenser 3, and includes a flushing valve interface 32 communicated with the outside, and a flushing flow channel 33 which is communicated with the flushing valve interface and arranged annularly along the air inlet of the condenser 1. The flushing port 30 is arranged along the edge of the flushing flow channel to flush the hot and humid air inside the condenser (refer to Figure 5 ).

[0030] Such as image 3 and Figure 4 As shown, the condenser 3 of the present invention is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com