High-bulk coating white cardboard and production process thereof

A cloth white cardboard, production process technology, applied in the direction of paper/cardboard layered products, paper, papermaking, etc., can solve problems such as stiffness, low bulk, cardboard folding, foaming and delamination, unfavorable printing or packaging effects, etc. , achieve the effects of clear dots, increased paper thickness, and no creases and bursts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

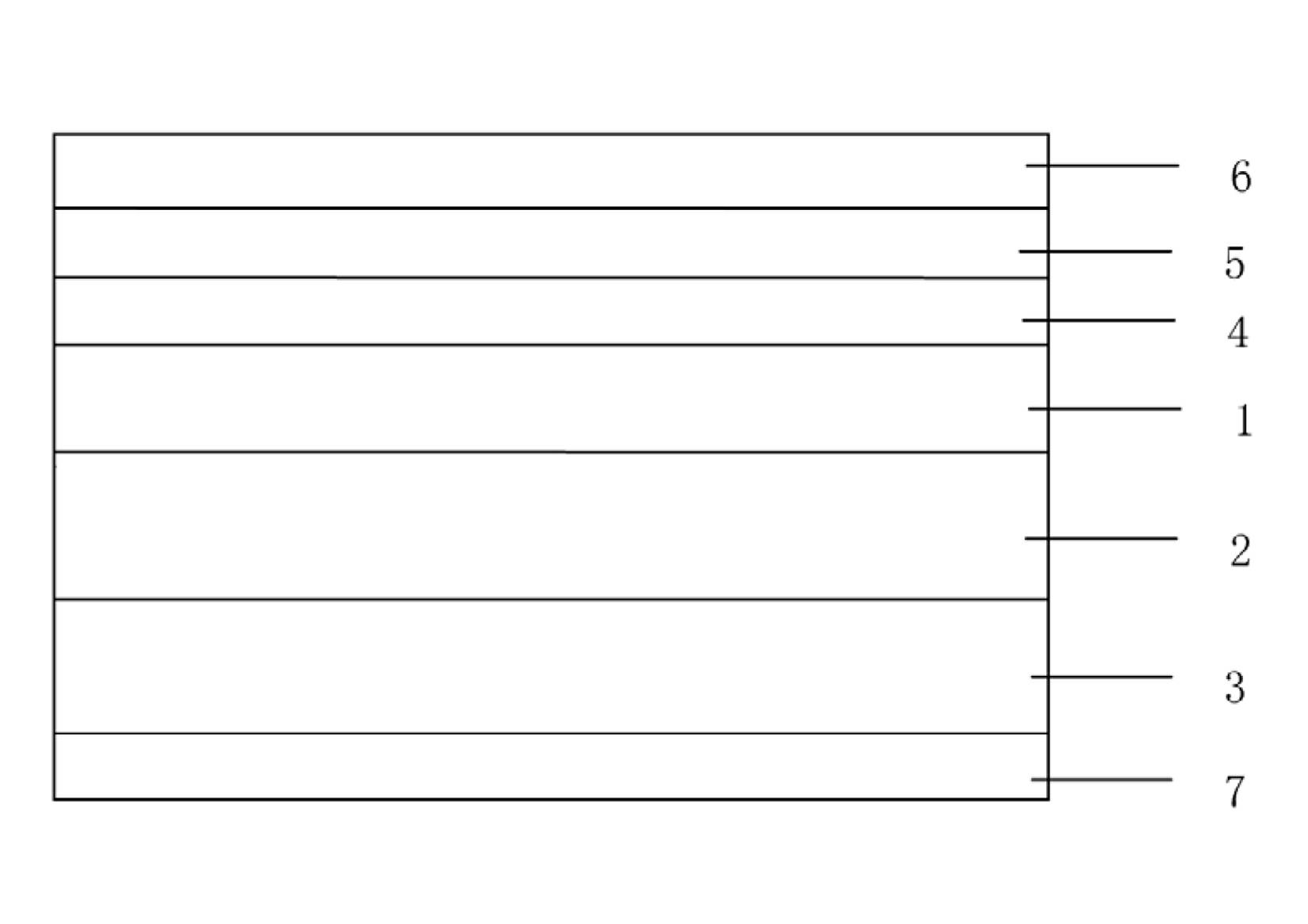

Image

Examples

Embodiment 1

[0034] 230g / m 2 High bulk coated white cardboard with white background:

[0035] 1) Pulping:

[0036] Flour: use 25wt% coniferous chemical kraft pulp NBKP, 75wt% broadleaf chemical kraft pulp LBKP; the pulp is pulped, refined, and wet-end chemicals without fillers and AKD are added to make noodles pulp;

[0037] Core pulp: 70wt% eucalyptus chemical-mechanical pulp BCTMP, 30wt% birch chemical-mechanical pulp BCTMP; after pulping and refining, add 4kg / ton pulp of AKD and other wet-end chemicals without fillers, Prepare the core pulp;

[0038] Bottom pulp: use 25wt% softwood chemical kraft pulp NBKP, 75wt% broadleaf chemical kraft pulp LBKP; the pulp is pulped, refined, and wet-end chemicals without fillers and AKD are added to make bottom pulp;

[0039] 2) Preparation of base paper:

[0040] The water filtration vacuum of the high vacuum box of the core mesh is -0.25bar, and the quantitative value of the surface layer is 30 g / m 2 , core weight 135g / m 2 , bottom layer qua...

Embodiment 2

[0048] 370g / m 2 High bulk coated white cardboard with white background:

[0049] 1) Pulping:

[0050] Flour: use 30wt% coniferous wood chemical kraft pulp NBKP, 70wt% hardwood chemical kraft pulp NBKP; the pulp is pulped, refined, and wet-end chemicals without fillers and AKD are added to make the flour pulp;

[0051] Core pulp: 75wt% eucalyptus chemical mechanical pulp BCTMP, 25wt% spruce chemical mechanical pulp BCTMP; the pulp is pulped and refined, and 5kg of AKD and other wet-end chemicals without fillers are added. Core pulp;

[0052] Base stock: use 35wt% coniferous wood chemical kraft pulp NBKP, 65wt% hardwood chemical kraft pulp NBKP; the pulp is pulped, refined, and wet-end chemicals without fillers and AKD are added to prepare the base stock.

[0053] 2) Preparation of base paper:

[0054] The water filtration vacuum of the high vacuum box of the core mesh is -0.3bar, and the quantitative value of the surface layer is 34 g / m 2 , core weight 263 g / m 2 , bot...

Embodiment 3

[0062] 330 g / m 2 High bulk coated white cardboard with white background:

[0063] 1) Pulping:

[0064] Flour: use 35wt% coniferous wood chemical kraft pulp NBKP, 65wt% hardwood chemical kraft pulp NBKP; the pulp is pulped, refined, and wet-end chemicals without fillers and AKD are added to make the flour pulp;

[0065] Core pulp: adopt 50wt% maple chemical mechanical pulp BCTMP, 50wt% spruce chemical mechanical pulp BCTMP; the pulp is pulped and refined, and 5kg / ton of pulp is added with AKD and other wet-end chemicals without fillers. core pulp;

[0066] Base stock: use 30wt% coniferous wood chemical kraft pulp NBKP, 70wt% hardwood chemical kraft pulp NBKP; the pulp is pulped, refined, and wet-end chemicals without fillers and AKD are added to prepare the base stock.

[0067] 2) Preparation of base paper:

[0068] The water filtration vacuum of the high vacuum box of the core mesh is -0.33bar, and the surface weight is 26 g / m 2 , core weight 232g / m 2 , bottom layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk | aaaaa | aaaaa |

| Bulk | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com