Method for construction of measurement and pavement of GRP (ground reference point) of ballastless track reference network

A ballastless track and construction method technology, applied in tracks, track maintenance, roads, etc., can solve the problems of long time for GRP measurement, slow measurement and installation, difficult to guarantee accuracy, etc., achieving significant social and economic benefits, improved accuracy, The effect of reducing investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings.

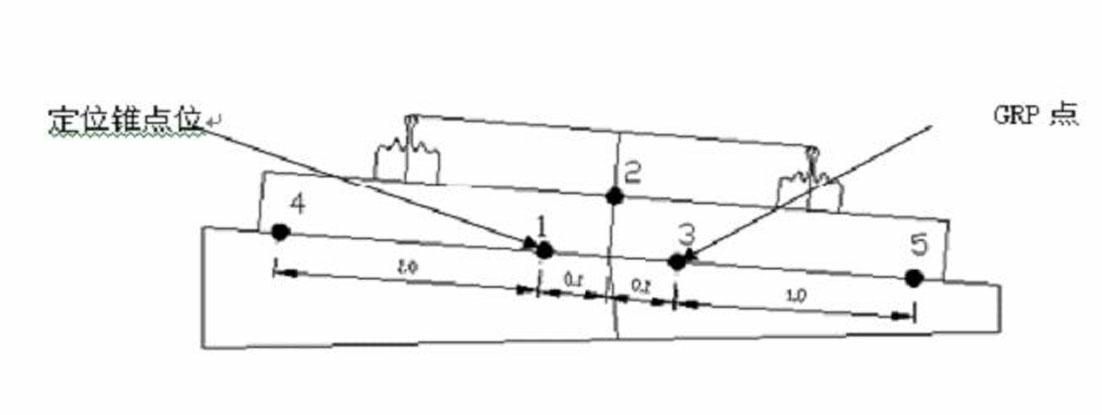

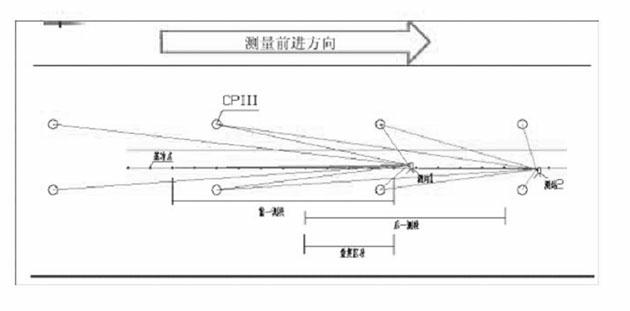

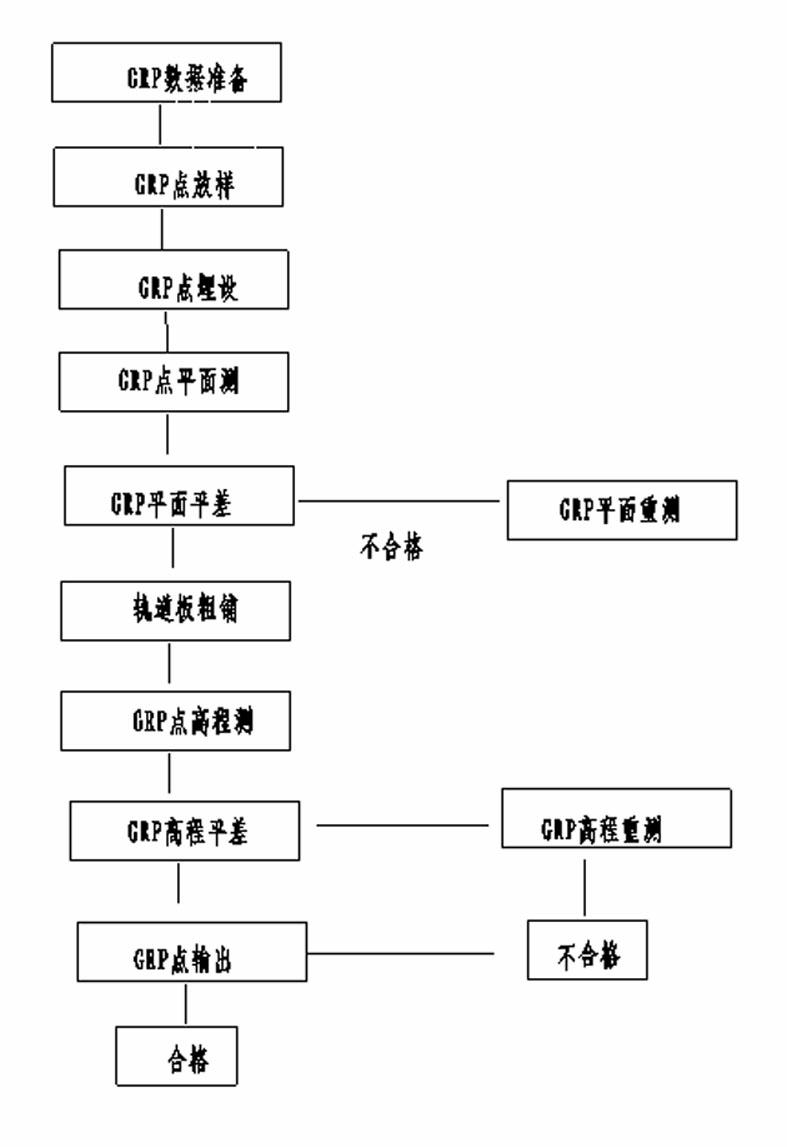

[0023] Such as figure 1 , 2 , The ballastless track track datum network GRP survey construction method shown in 3, comprises the following steps:

[0024] (1) GRP point stakeout

[0025] The track reference network GRP is based on the track control network CPIII and provides a control network for the laying and fine adjustment of the track slab. The GRP is arranged between the track axes, and the connection between the positioning cone and the GRP is perpendicular to the track axis. The center line is 0.10m, and the GRP point is generally buried on the lower side, that is, the joint between the two track slabs;

[0026] The coordinates of GPR points should be calculated in advance so that they are at the design position when setting out. The coordinates of these points can be directly calculated by the software. The positions of the stakeout points should be c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com