Method for detecting surface figures of large-aperture off-axis convex aspheric mirror

A detection method and reflective mirror technology, applied in measuring devices, instruments, optical devices, etc., can solve problems such as complex structure, large compensator aperture, and large number of sub-apertures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

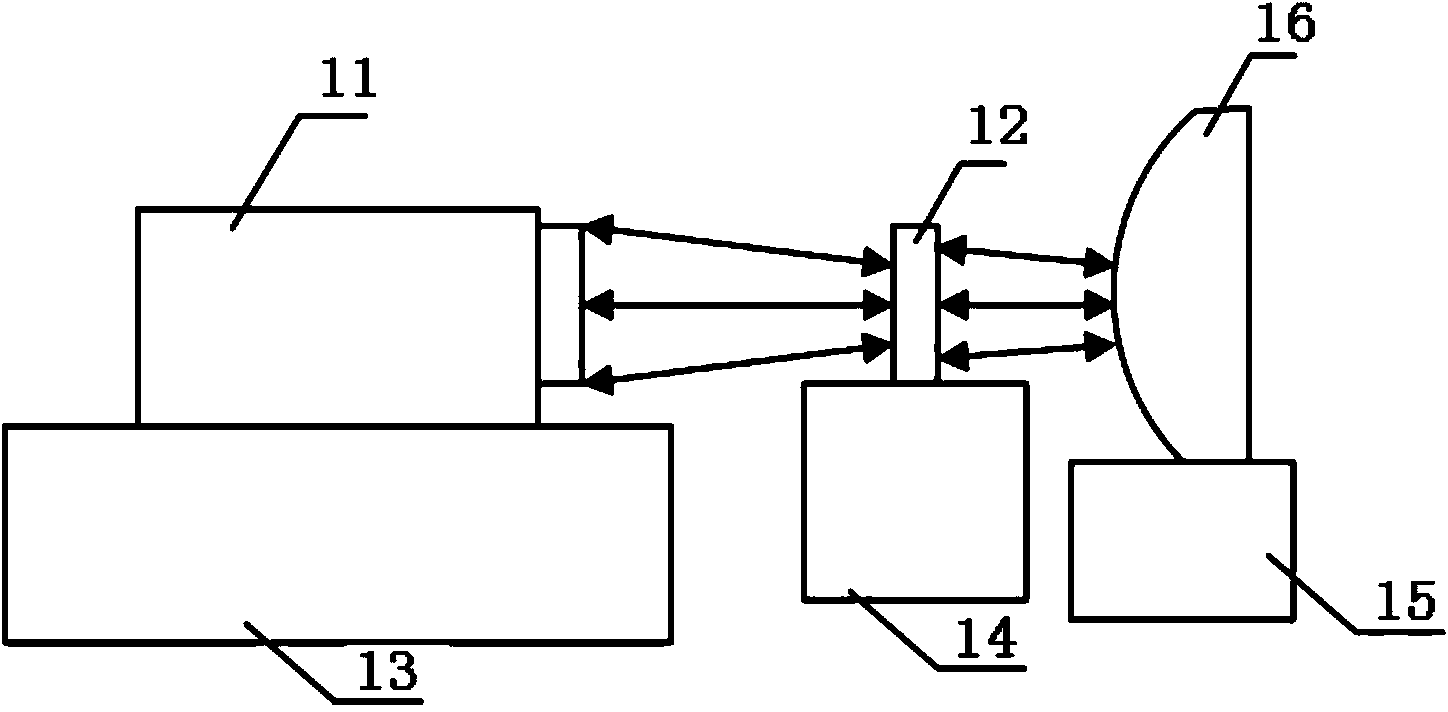

[0042] like figure 1 As shown, the device for realizing the large-diameter off-axis convex aspheric mirror surface shape detection method of the present invention includes a laser interferometer 11, a calculation holographic element 12, a first adjustment mechanism 13, a second adjustment mechanism 14, a third adjustment mechanism 15 and The large-diameter off-axis convex aspheric surface 16 to be tested.

[0043] The first adjustment mechanism 13 adopts a currently known three-dimensional precision adjustment frame, which can accurately control the translation of the interferometer 11 along the X direction, the Y direction and the Z direction (optical axis direction). The second adjustment mechanism 14 adopts a currently known six-dimensional precision adjustment frame, which can accurately adjust the pitch, yaw, and rotation of the computational holographic element 12, as well as the translation along the X direction, Y direction, and Z direction (optical axis direction). T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com