High-power fiber laser

A fiber laser, high-power technology, used in lasers, laser parts, phonon exciters, etc., can solve the problem of reducing signal laser power and conversion efficiency, affecting the stability and reliability of high-power fiber lasers, and damage to optical devices, etc. problems, to achieve the effect of suppressing nonlinear effects, reducing the number of fiber splices, and increasing power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

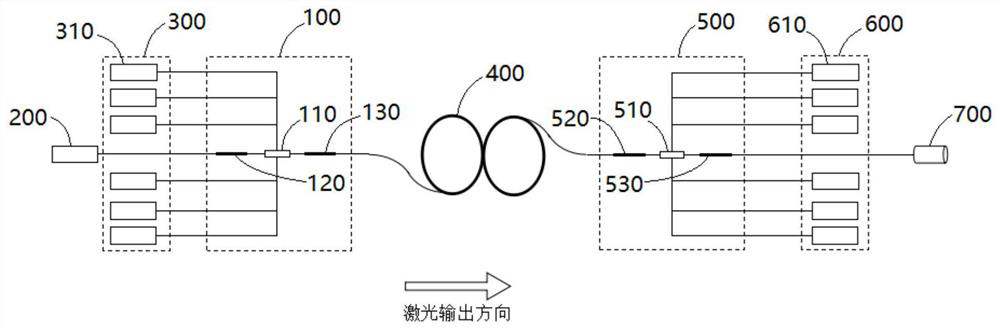

[0033] see figure 1 , shown in the figure is a high-power fiber laser, which adopts a bidirectional pumping method, which includes an integrated optical fiber device module 100, an indicator light laser module 200, a semiconductor laser module 300, a gain fiber 400, an integrated optical fiber device module 500, and a semiconductor laser module. Laser module 600 and output optical cable 700.

[0034] The integrated optical fiber device module 100 has several laser beam input ports and a laser beam output port. The laser beam output end of the indicator light laser module 200 is correspondingly connected to the laser beam input end of the integrated optical fiber device module 100 . Each laser beam output port of the semiconductor laser module 300 is correspondingly connected to the laser beam input port of the integrated optical fiber device module 100 . The semiconductor laser module 300 is composed of several semiconductor lasers 310 . The input end of the gain fiber 400 ...

Embodiment 2

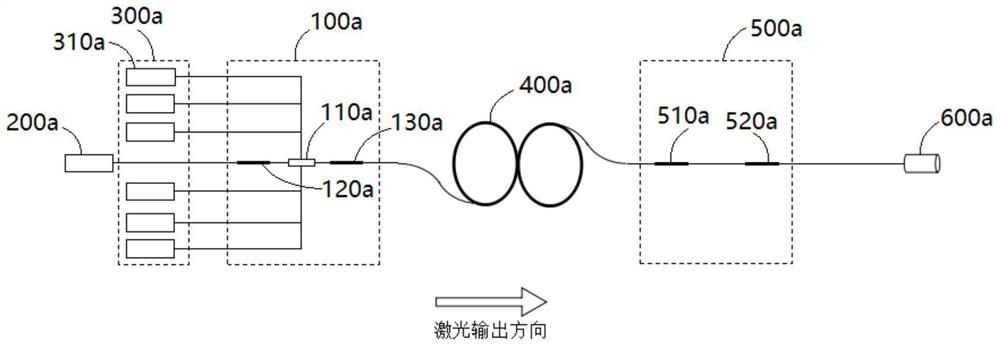

[0041] see figure 2 , shown in the figure is a high-power fiber laser, which adopts a unidirectional pumping method, which includes an integrated optical fiber device module 100a, an indicating light laser module 200a, a semiconductor laser module 300a, a gain fiber 400a, an integrated optical fiber device module 500a and Output fiber optic cable 600a.

[0042] The integrated optical fiber device module 100a has several laser beam input ports and a laser beam output port. The laser beam output end of the indicator light laser module 200a is correspondingly connected to the laser beam input end of the integrated optical fiber device module 100a. Each laser beam output port of the semiconductor laser module 300a is correspondingly connected to the laser beam input port of the integrated optical fiber device module 100a. The semiconductor laser module 300a is composed of several semiconductor lasers 310a. The input end of the gain fiber 400a is connected to the output end of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com