Ultra-high numerical aperture combined variable magnification extreme ultraviolet lithography objective lens and optimization method

An extreme ultraviolet lithography and objective lens technology, which is applied in the fields of optical design, semiconductor manufacturing equipment and chip manufacturing, can solve the problem that the method and example of the film layer of the extreme ultraviolet lithography objective lens are not fully disclosed, and the reflection characteristics of the objective lens are not reported. , It is difficult to obtain a uniform and high reflectivity film layer, etc., to achieve the effect of improving the quality and efficiency of lithography, excellent imaging quality, and reducing the number of splices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in detail below with reference to the accompanying drawings and examples.

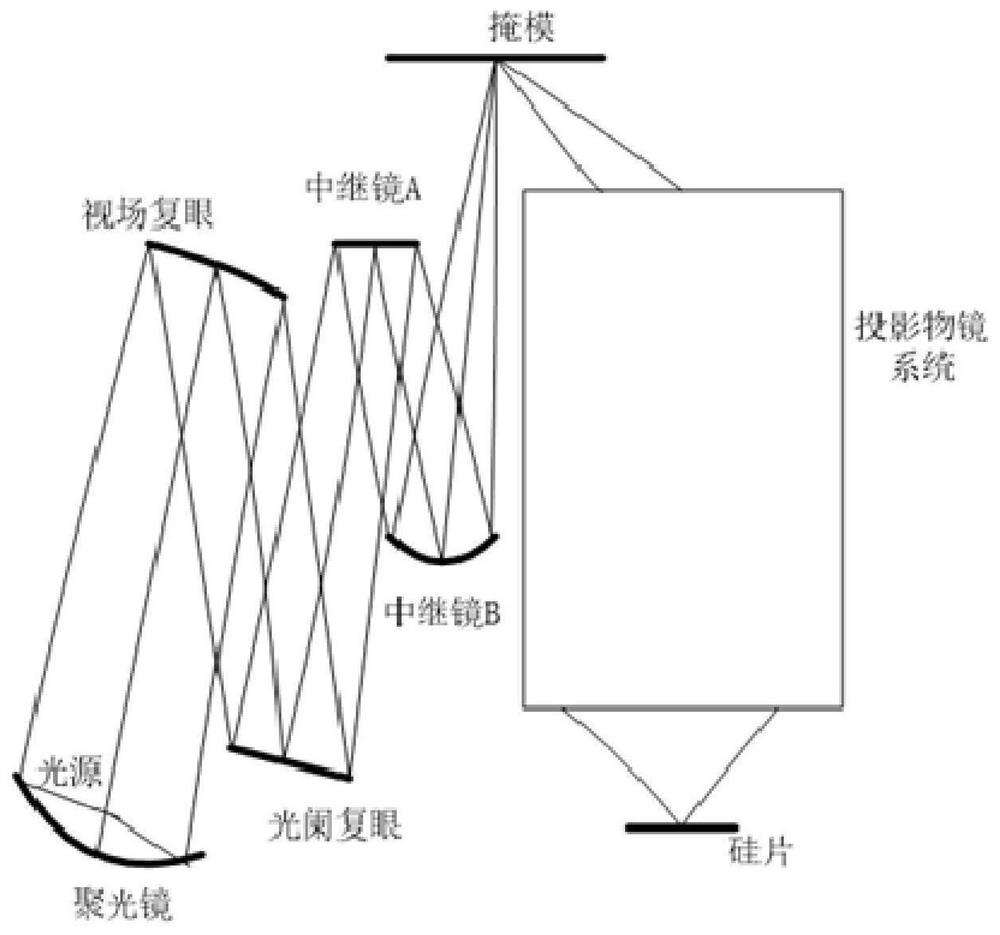

[0045] According to the present invention, we realize that the size of the image field of view perpendicular to the scanning direction can be increased by the variable magnification imaging optical system, the number of splicing of the image field can be reduced, and the lithography efficiency can be improved to the maximum.

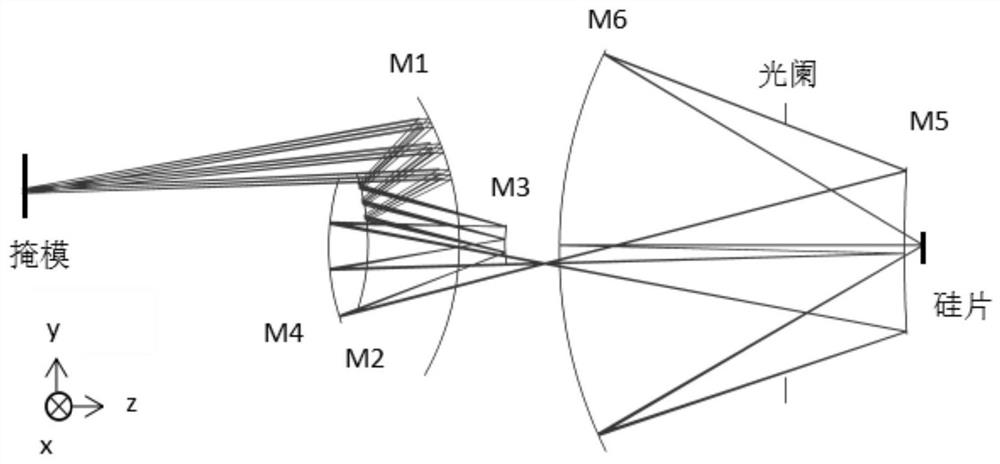

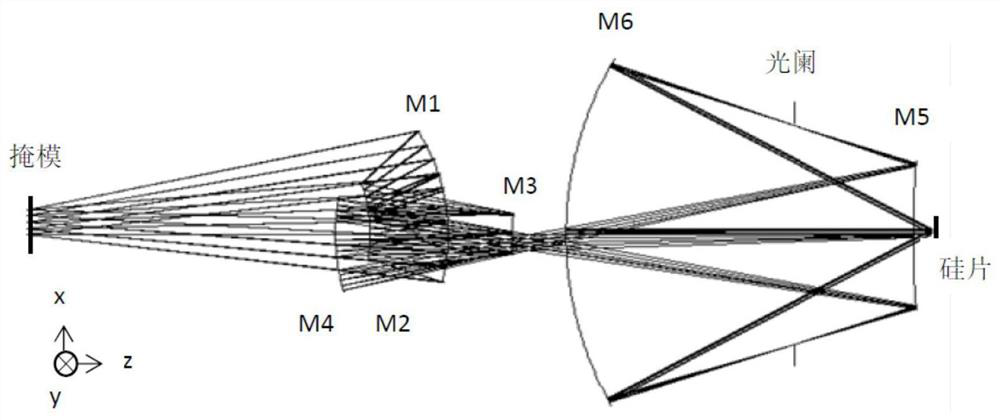

[0046] The lithography objective system of the present invention has a circular exit pupil, so the image-side numerical aperture is direction-independent. The lithography objective lens system of the present invention has an elliptical entrance pupil, and the semi-axes have the same or opposite relationship, which is related to different object-side numerical apertures or imaging sizes.

[0047] The variable magnification objective lens system of the present invention includes at least six mirror surfaces. Large numbers of mirrors a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com