Imaging optical microfluid sensing device and method thereof

A sensing device and microfluidic technology, applied in the fields of photobiology and chemical sensing, can solve the problems of inability to achieve high-throughput and rapid measurement, and achieve the effect of easy implementation and mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

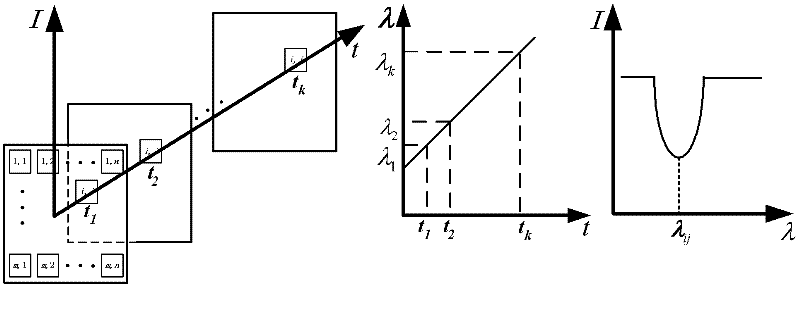

[0031] Embodiment 1: The principle of signal control and processing unit to detect the resonant wavelength of optical microfluidic resonant cavity

[0032] Each pixel unit of the m×n array photodetector is in one-to-one correspondence with each unit in the m×n optical microfluidic resonant cavity array, wherein m is the number of rows, and n is the number of columns. like figure 1 As shown, for the (i, j)th pixel unit of the m×n array photodetector, i=1, Λ, m, j=1, Λ, n, the signal control and processing unit continuously tunes the laser output wavelength, The output wavelength varies with time t, at t 1 , t 2 ......t k At different times, the corresponding light wavelengths are λ 1 ,λ 2 ,Λ,λ k , while tuning, synchronously control the array photodetector to record the image P corresponding to each light wavelength 1 , P 2 ,Λ,P k . The signal control and processing unit extracts the series of images, that is, extracts the (i, j)th pixel P for each image l (i, j), l=...

Embodiment 2

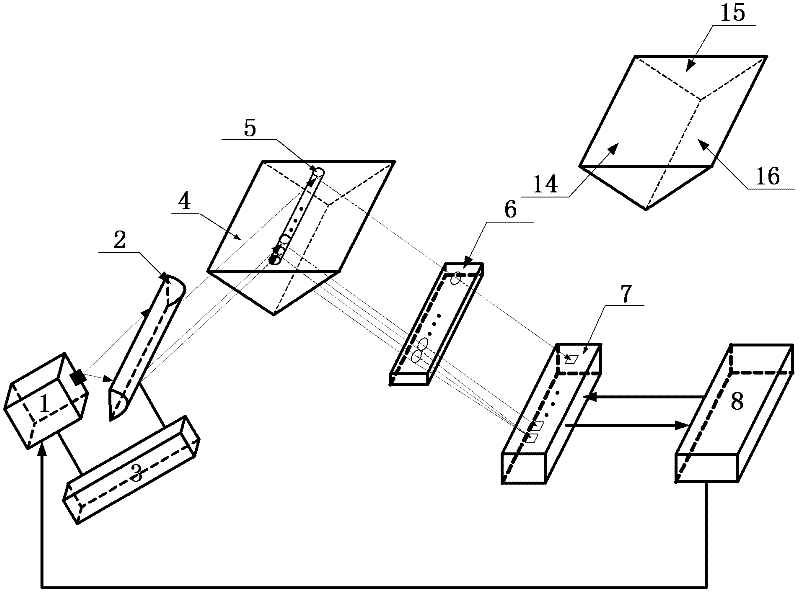

[0033] Embodiment 2: A sensing device and method using a one-dimensional optical-microfluidic resonant cavity array based on different positions of a single microtube along the axial direction

[0034] like figure 2 As shown, the sensing device includes: a tunable laser light source 1 is located on an incident angle adjustment frame 3 and is connected to a signal control and processing unit 8. The tunable laser light source is an erbium-doped tunable fiber laser with a wavelength range of 1525 to 1560 nm; The surface collimator lens 2 is located on the incident angle adjustment frame 3, and its plane part is perpendicular to the optical axis of the tunable laser light source 1; the reflective prism 4 is a right-angle prism, and the size of its reflective surface 15 is 24mm×36mm, and the incident angle of the reflective prism 4 The surface 14 is facing the convex surface of the collimating lens 2, and the outgoing surface 16 of the reflecting prism 4 is facing the linear micro...

Embodiment 3

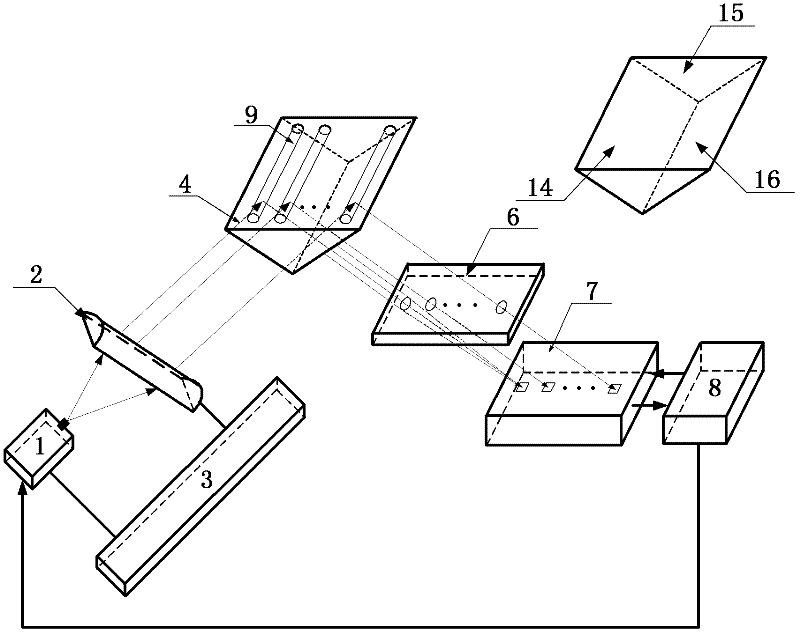

[0037] Embodiment 3: A sensing device and method using a one-dimensional optical-microfluidic resonant cavity array based on multiple microtubes arranged side by side

[0038] like image 3 As shown, the sensing device includes: a tunable laser light source 1 is located on an incident angle adjustment frame 3 and is connected to a signal control and processing unit 8. The tunable laser light source is an erbium-doped tunable fiber laser with a wavelength range of 1525 to 1560 nm; The surface collimator lens 2 is located on the incident angle adjustment frame 3, and its plane part is perpendicular to the optical axis of the tunable laser light source 1; the reflective prism 4 is a right-angle prism, and the size of its reflective surface 15 is 24mm×36mm, and the incident angle of the reflective prism 4 The surface 14 is facing the convex surface of the collimating lens 2, and the outgoing surface 16 of the reflective prism 4 is facing the linear microlens array 6, and the refle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com