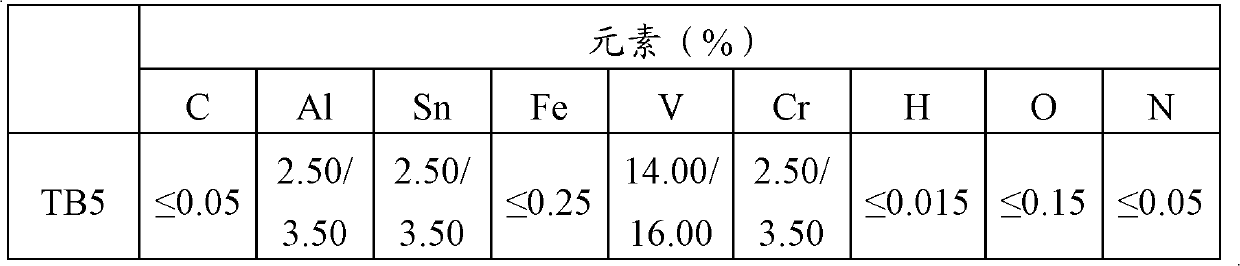

Method for measuring vanadium element in titanium alloy

A measurement method, titanium alloy technology, applied in the direction of material excitation analysis, thermal excitation analysis, etc., can solve the problems of spectral line interference, poor precision and accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0026] Weigh 0.1000g (accurate to 0.0001g) titanium alloy sample with a vanadium content of 15.10% in a 200mL conical flask, add 10mL sulfuric acid (1+1), heat at low temperature until the sample is basically dissolved completely, add a few drops of nitric acid, continue Heat at low temperature until it is completely decomposed, and the test solution is boiled to 5mL. Cool to room temperature, quantitatively transfer the solution to a 200mL volumetric flask, dilute to the mark with high-purity water, and mix well to obtain the solution to be tested. The solution to be tested was analyzed under the following conditions: analytical spectral line 290.880nm, high-frequency power 1300W, atomizing gas flow rate 0.75L / min, auxiliary gas flow rate 0.20L / min, sample lifting volume 1.6mL / min, observation method: axis Towards, using an inductively coupled plasma emission spectrometer to measure the spectral line intensity is 3016500.2, and according to the standard working curve, the con...

example 2

[0028] Weigh 0.1000g (accurate to 0.0001g) titanium alloy sample with a vanadium content of 15.10% in a 200mL conical flask, add 15mL sulfuric acid (1+1), heat at low temperature until the sample is basically dissolved completely, add a few drops of nitric acid, continue Heat at low temperature until it is completely decomposed, and cook the test solution to 8mL. Cool to room temperature, quantitatively transfer the solution to a 200mL volumetric flask, dilute to the mark with high-purity water, and mix well to obtain the solution to be tested. The solution to be tested was analyzed under the following conditions: analytical spectral line of 290.880nm, high-frequency power of 1300W, atomizing gas flow rate of 0.80L / min, auxiliary gas flow rate of 0.20L / min, sample lifting volume of 1.7mL / min, observation method: axis Towards, using the inductively coupled plasma emission spectrometer to measure the spectral line intensity is 3031668.0, and according to the standard working cur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com