Defect detection device for mask plate

A defect detection and mask technology, applied in the direction of optical testing flaws/defects, etc., can solve the problem of time-consuming, difficult to find the subtle organic contamination of the mask, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

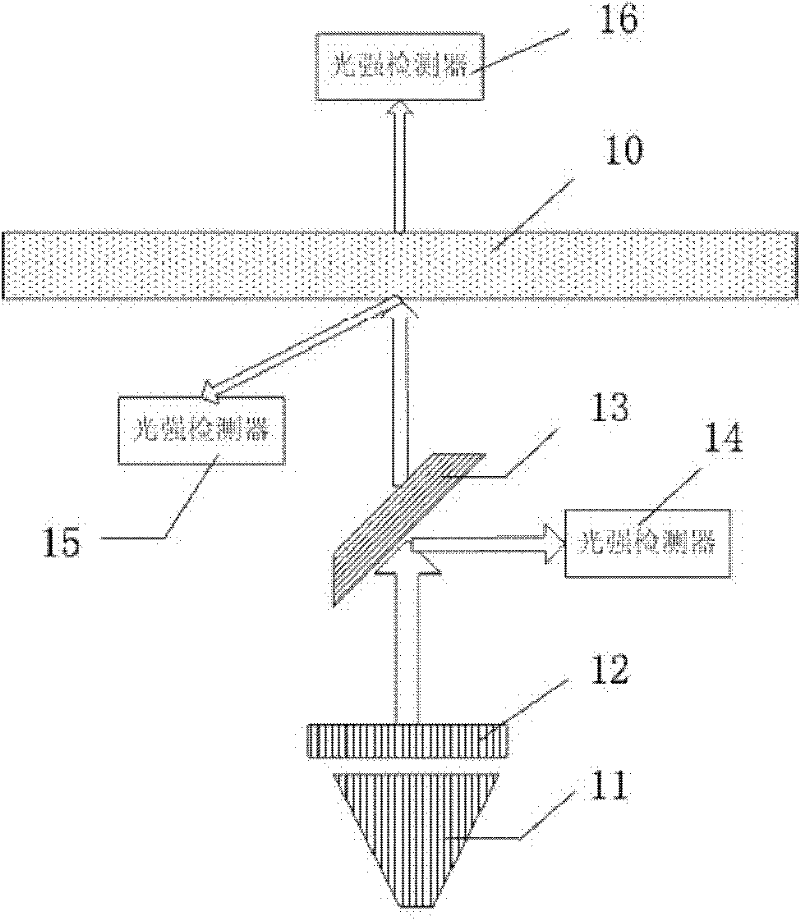

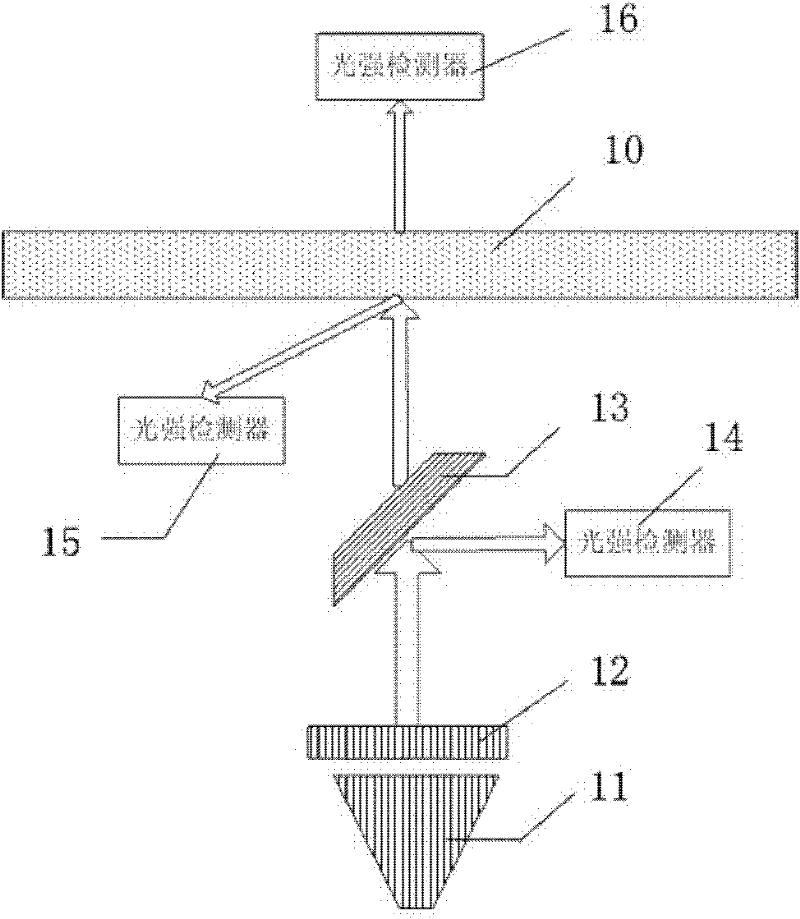

[0016] According to an embodiment of the present invention, the light source projection device further includes an incident angle adjustment mechanism for adjusting the incident angle of the light beam. When the incident angle of the light beam changes, its reflected light intensity and transmitted light intensity will change accordingly, and then the reflectivity and transmittance of the mask plate to the light beam will also change.

[0017] According to another embodiment of the present invention, according to a preferred embodiment of the present invention, the light source 11 is a tunable laser that emits a laser beam with a variable wavelength, and the wavelength of the laser beam emitted by the tunable laser is 157nm, 193nm, 248nm or 257nm .

[0018] According to another embodiment of the present invention, the light source 11 is a halogen light source, and the emitted light beam can be adjusted to have a wavelength range of 120nm to 800nm through a filter.

[0019] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com