Method and system for monitoring plastic deformation process and defects

A plastic deformation and defect technology, applied in general control systems, control/regulation systems, program control, etc., can solve problems such as inability to adapt to online monitoring, failure to consider forming process problems, and failure to address problems, achieving easy installation, Avoid bias, high sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] System block diagram as figure 1 shown by figure 1 It can be seen that a monitoring system implementing the present invention is mainly composed of an acceleration vibration sensor, signal acquisition and storage, digital signal processing, visualization module, control unit or remote communication module.

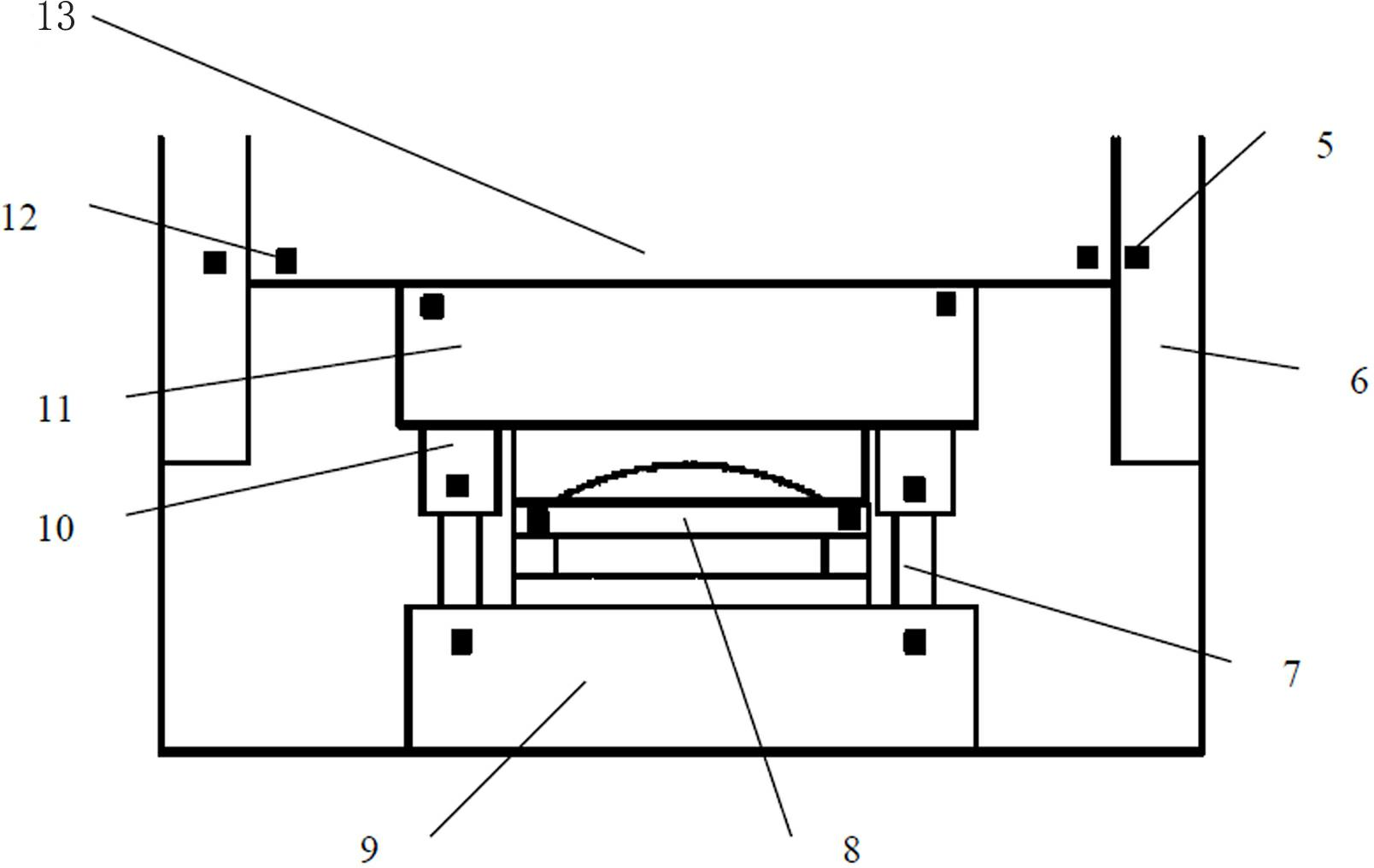

[0033] A typical example is figure 2 , 3 As shown, the acceleration vibration sensor 1 is installed on the column 2 of the press, the upper beam 3, the slider 13, the base 4, the upper die 11, the lower die 9, the guide sleeve 10, the blank holder 8, the press guide rail 6, the mold On the guide post 7 and other components, the installation position is selected according to different press equipment, and the most sensitive position to the process is selected. These components may appear as attached Figure 4 The degrees of freedom shown vibrate, so no less than two acceleration sensors should be used to complete signal acquisition. Simultaneously in order to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com