Inductor and method for forming same

A technology of inductance and inductance coil, applied in the field of high-Q-value inductance and formation, can solve the problem of increasing process steps, and achieve the effects of reducing dielectric constant, increasing Q value, and reducing parasitic capacitance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

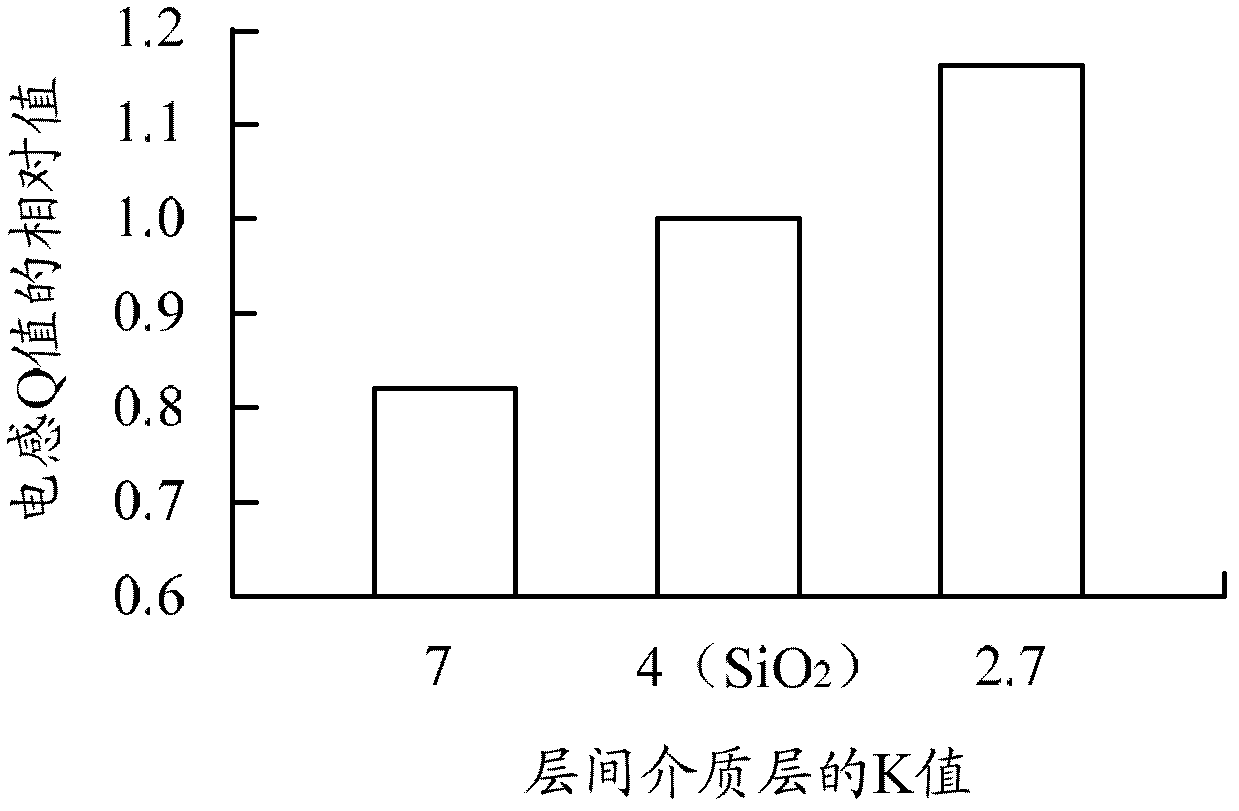

[0034] As mentioned in the background technology, how to realize a sufficiently high Q value inductor in the semiconductor manufacturing process is a big problem. In the prior art, the methods to improve the Q value of the inductor are mostly changing the characteristics and structure of the substrate material, increasing the substrate shielding, etc. , but because changing the substrate material requires changing the manufacturing process, adding a substrate shielding layer can only slightly increase the Q value, and requires additional processes to form the substrate shielding layer, all of which have their own shortcomings.

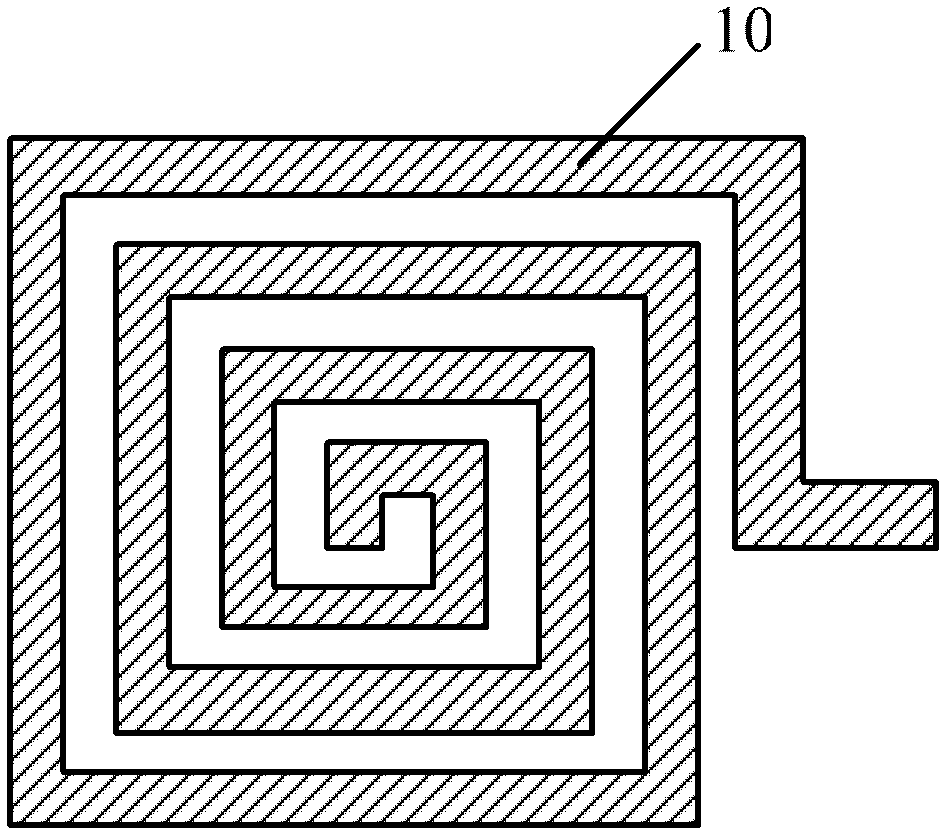

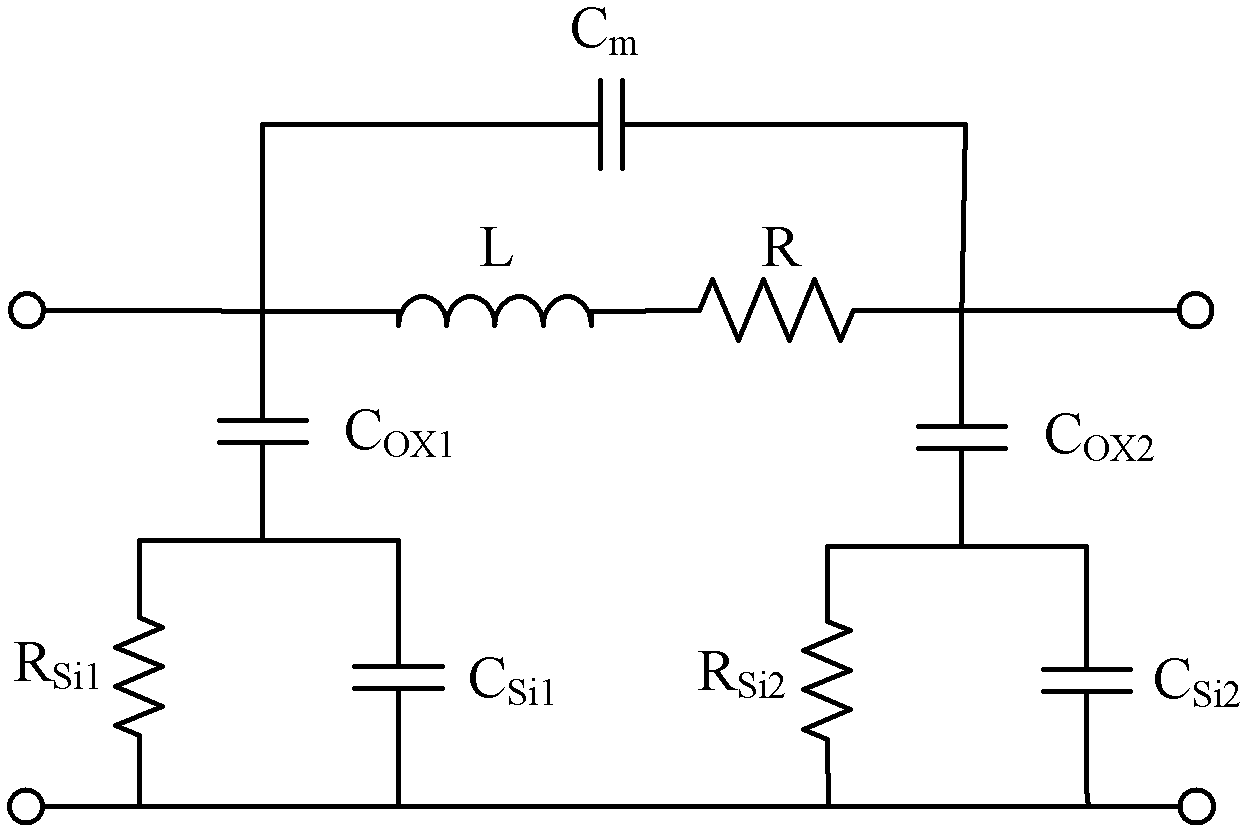

[0035] Therefore, the inventor has found through research that the planar spiral inductor is generally realized by forming a single-layer or multi-layer spiral metal wire on the interlayer dielectric layer on the surface of the semiconductor substrate by CMOS technology, and the single-layer or multi-layer spiral metal wire is used as the inductor Coil,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com