Sliding liner plate apparatus used in installation bracket

A technology for installing brackets and liners, which is applied in the direction of support structure installation, non-rotational vibration suppression, etc. It can solve the problems of affecting the appearance, strong connectors, and large surface friction, so that it is not easy to peel off or fall off, and it is easy to maintain. and replacement, the effect of high flatness accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

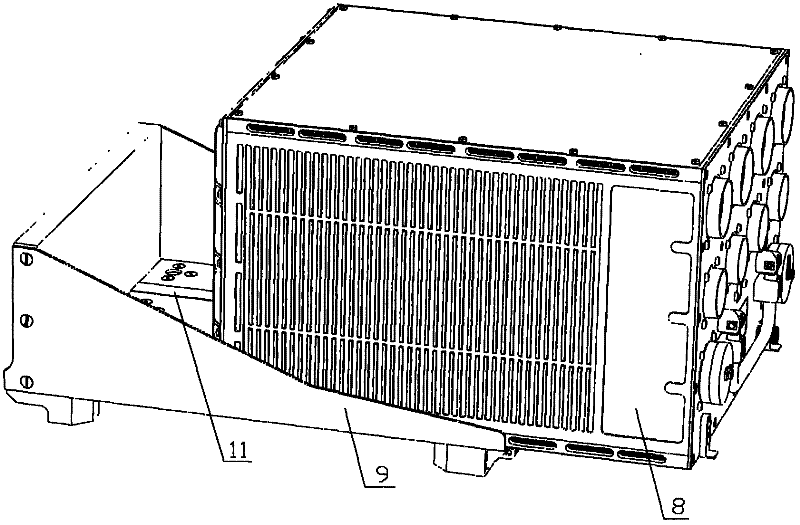

[0019] The application position of the present invention in avionics equipment is as figure 1 As shown, the sliding liner 11 provides a low-friction contact surface between the lower surface of the electronic equipment cabinet 8 and the upper surface of the mounting bracket 9 .

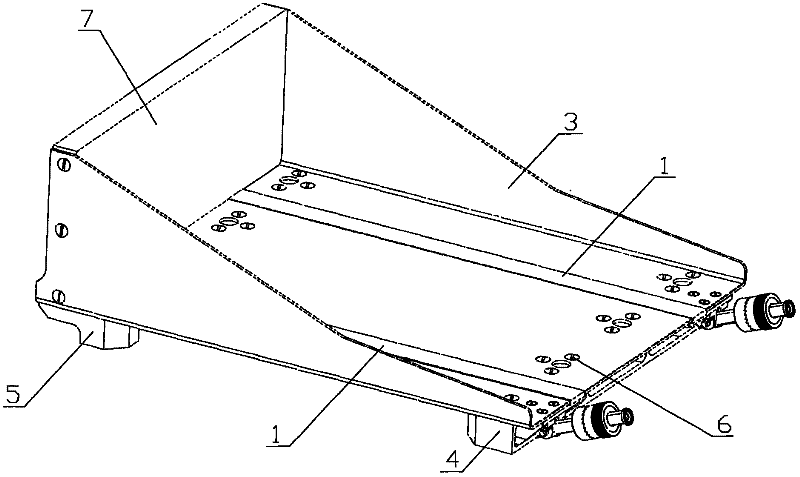

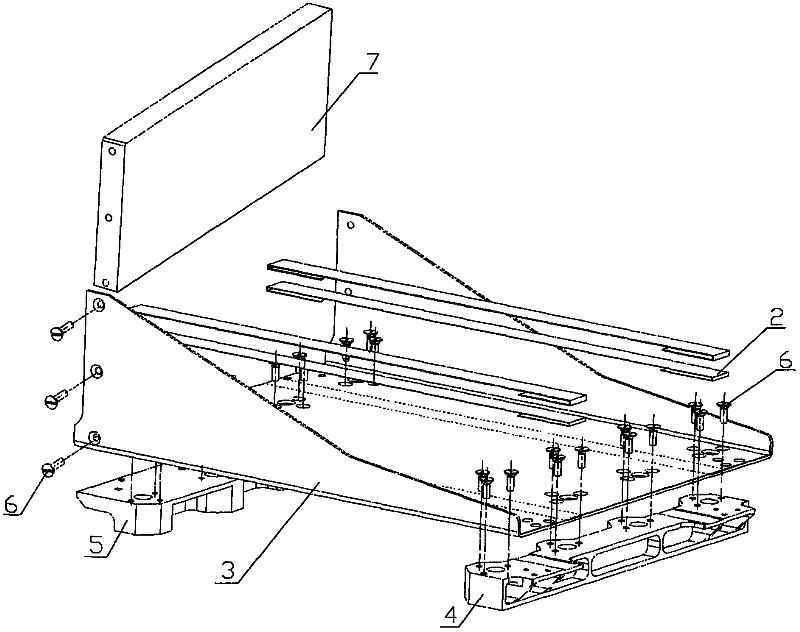

[0020] From figure 2 It can be seen that the sliding liner 11 is an integral part of the structure of the mounting bracket 9, and the liner 1 and the double-sided adhesive film 2 are usually used in pairs. , pressure of 0.5MPa and bonded to the upper surface of the bottom of the supporting plate 3 to form two smooth sliding contact planes. The part of the liner 1 and the double-sided adhesive film 2 that exceeds the length of the supporting plate is bent downward and bonded to the lower surface of the bottom of the supporting plate 3, and the bending degree meets the requirements of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com