Method for producing double aerosol container, double aerosol container, and apparatus for producing double aerosol container

A manufacturing method and aerosol technology, applied in the direction of injection device, distribution device, liquid injection device, etc., can solve the problems of drop, low efficiency of insertion operation, deformation quality of inner bag, etc., and achieve high quality, stable quality and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

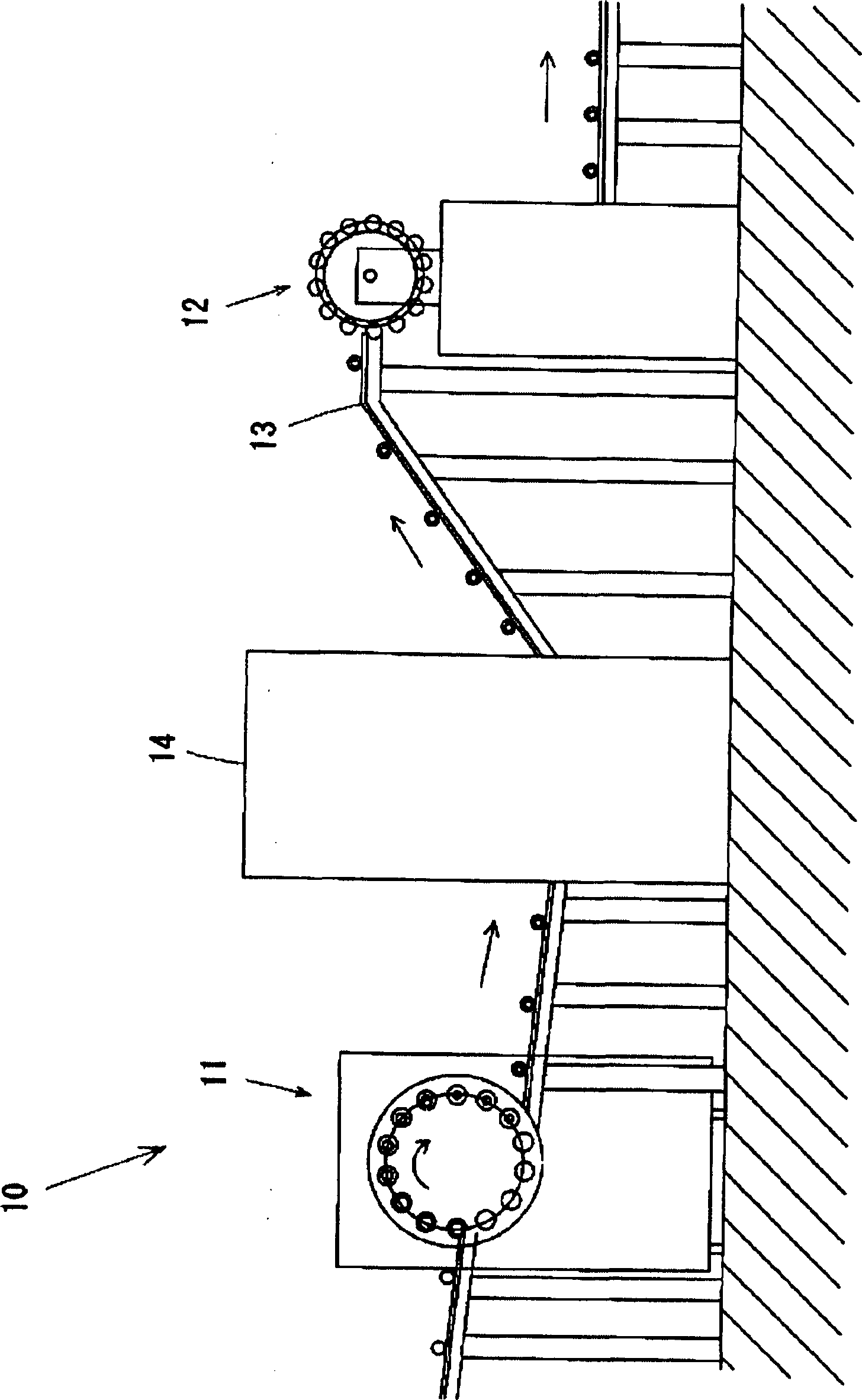

[0130] figure 1 The manufacturing device 10 of the double aerosol container is equipped with a shrinking machine 11 for forming a bottomed cylindrical container into a metal container, an inner bag inserting machine 12 for inserting an inner bag into the formed metal container, and a shrinking machine for shrinking. The machine-formed metal containers are transported to the conveyor 13 of the inner bag insertion special machine in turn. In addition, reference numeral 14 is a washing machine for washing metal containers, which is a conventionally known machine. In addition, the formed inner bags 30 are sequentially conveyed to the inner bag insertion machine 12 (not shown).

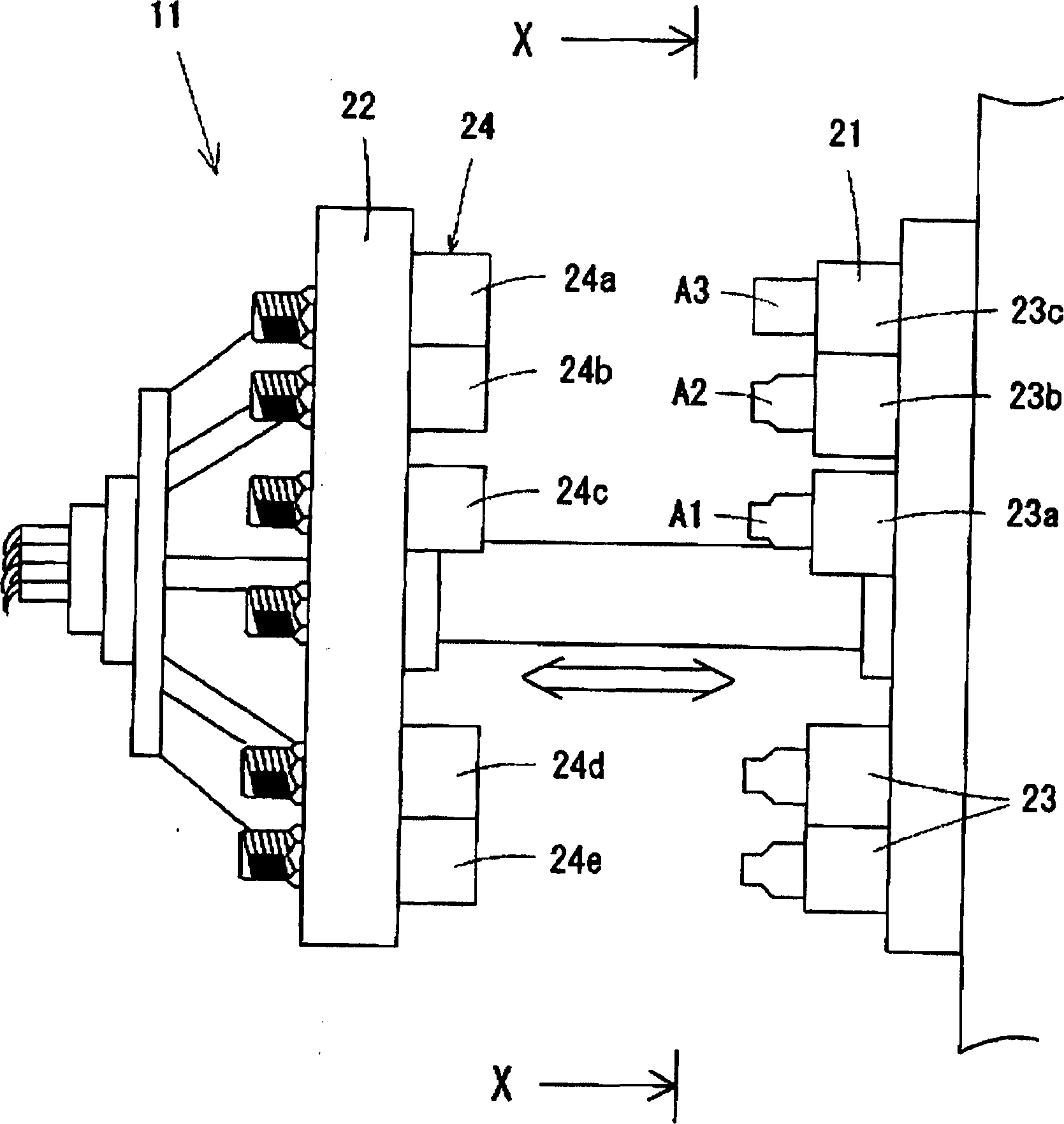

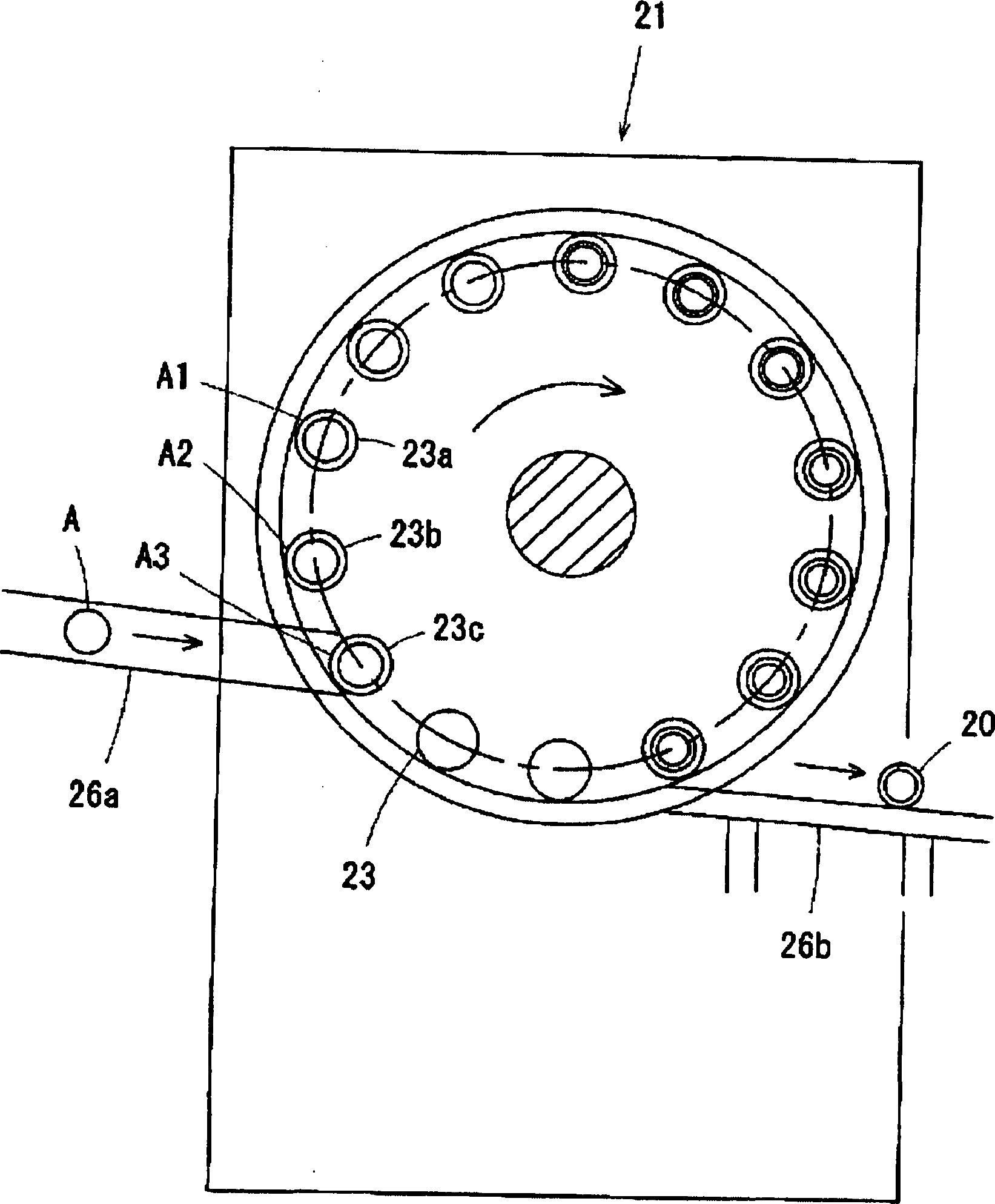

[0131] Such as figure 2 As shown, the necking machine 11 is composed of a rotary disk 21 and a reciprocating disk 22. The rotary disk 21 holds bottomed cylindrical containers (all containers from bottomed cylindrical containers to metal containers that are deformed by molds) intermittently. The recipr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com