Soybean walnut milk and preparation method thereof

A technology of walnut milk and soybean, which is applied in the field of soybean walnut milk and its preparation, can solve the problems of high cost, complicated equipment, and no perfect deodorization method, and achieve the effect of harmonious taste and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

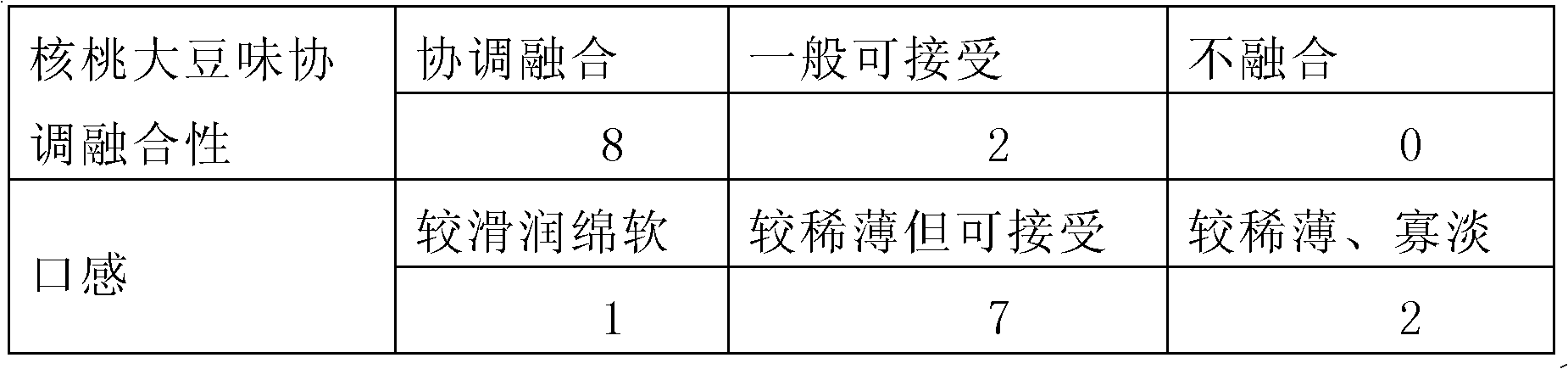

Embodiment 1

[0034] Embodiment 1, a kind of preparation of soybean walnut milk

[0035] Preparation of soy milk:

[0036] Use a crusher to crush the soybeans into 4-6 petals of crumbs, winnow the skin and sieve out the fine powder, put 4kg of crushed soybean cotyledon crumbs into 24kg of water at about 90°C for 4hrs, the hardness of the water used must first be Adjust to 1.5~2.5mmol / L (use MgCl if necessary 2 adjustment), the soaked cotyledon crumbs and soaking water are refined with a grinding wheel mill or a colloid mill, and the pH of the cotyledon and water mixture is measured before refining. According to the measurement results, in the process of refining, 1mol / L of NaOH, after refining, centrifuge to remove the bean dregs to obtain 27.5kg of soybean milk with a pH value of 7.3.

[0037] Preparation of walnut pulp:

[0038] Weigh 1 kg of walnut kernels and soak them in water at room temperature for 5 hours. The hardness of the soaked walnut kernels in water is 1.5-2.5mmol / L, remo...

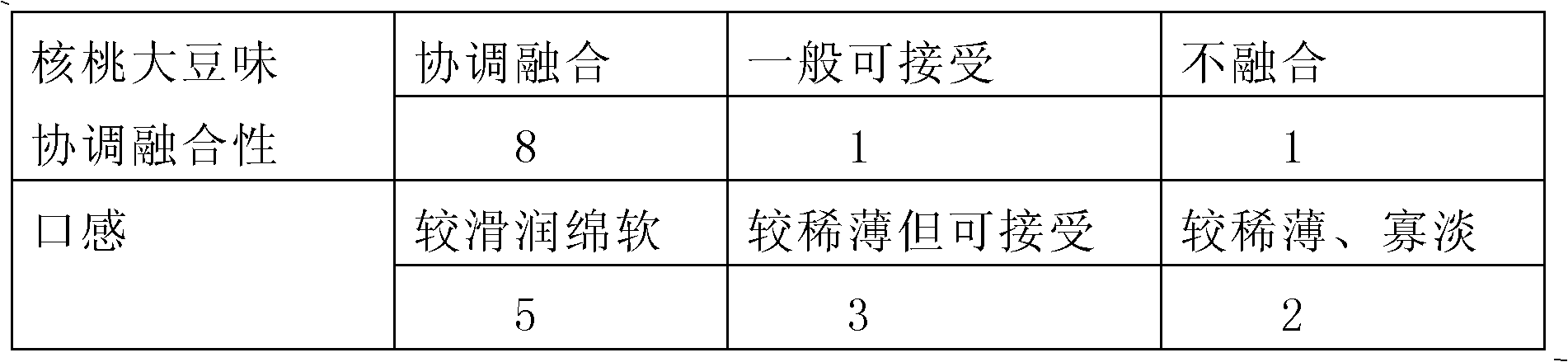

Embodiment 2

[0045] Preparation of soy milk:

[0046] Use a crusher to crush the soybeans into 4-6 petals of crumbs, winnow the skin and sieve out the fine powder. Soak 5kg of crushed soybean cotyledon crumbs in 35kg of water at about 90°C for 4hrs. The hardness of the water used must first be Adjust 1.5~2.5mmol / L (use CaCl if necessary 2 adjustment), the soaked cotyledon crumbs and soaking water are refined with a grinding wheel mill or a colloid mill, and the pH of the cotyledon and water mixture is measured before refining. According to the measurement results, in the process of refining, 1mol / L of NaOH, after refining and centrifuging to remove the bean dregs, 37.5kg of soybean milk with a pH value of 7.4 was obtained.

[0047] Preparation of walnut pulp:

[0048] Weigh 5 kg of walnut kernels, soak them in room temperature water for 6 hours, the hardness of the soaked walnut kernels in water is 1.5-2.5mmol / L, remove the water, put the walnut kernels into a NaOH solution with a tempe...

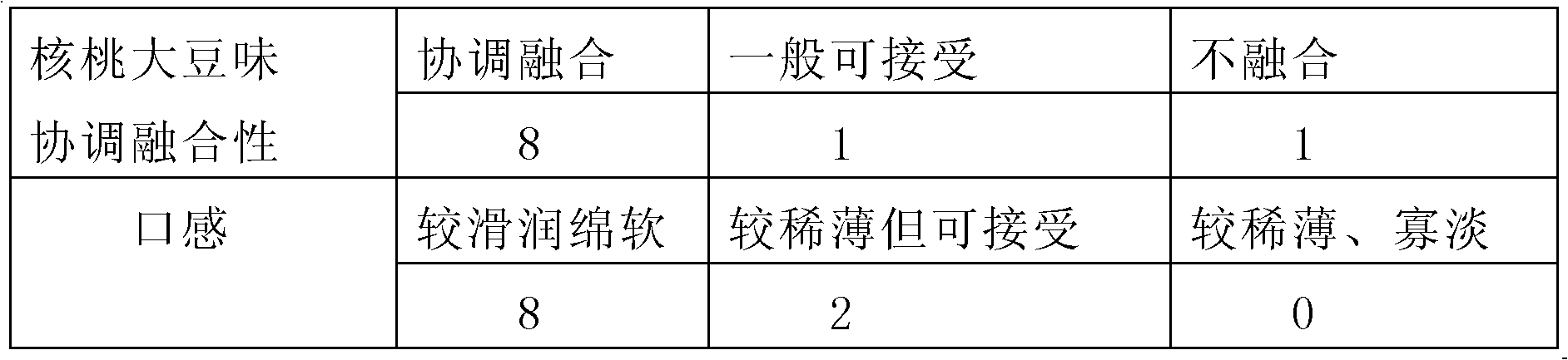

Embodiment 3

[0055] Preparation of soy milk:

[0056] Crush the soybeans into 4-6 petals of crumbs with a crusher, remove the skins by winnowing and sieve out the fine powder, put 5kg of crushed soybean cotyledon crumbs into 20kg of water at 90°C for 4hrs, and adjust the hardness of the water to 1.6~2.5mmol / L (use MgCl if necessary 2 adjustment), the soaked cotyledon crumbs and soaking water are refined with a grinding wheel mill or a colloid mill, and the pH of the cotyledon and water mixture is measured before refining. According to the measurement results, in the process of refining, 1mol / L of NaOH, after refining, centrifuge to remove the bean dregs to obtain 25.5kg of soybean milk with a pH value of 7.4.

[0057] Preparation of walnut pulp:

[0058] Weigh 5 kg of walnut kernels, soak them in room temperature water for 6 hours, the hardness of the soaked walnut kernels in water is 1.5-2.5mmol / L, remove the water, put the walnut kernels into a NaOH solution with a temperature of 75-8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com