Moissanite gem with bright carving surface and cutting and grinding processing methods thereof

A technology of moissanite and cutting, which is applied in the field of faceted bright cut moissanite gemstones and their cutting and grinding processing, and can solve problems such as the difficulty in the optimal cutting ratio of moissanite gemstones

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

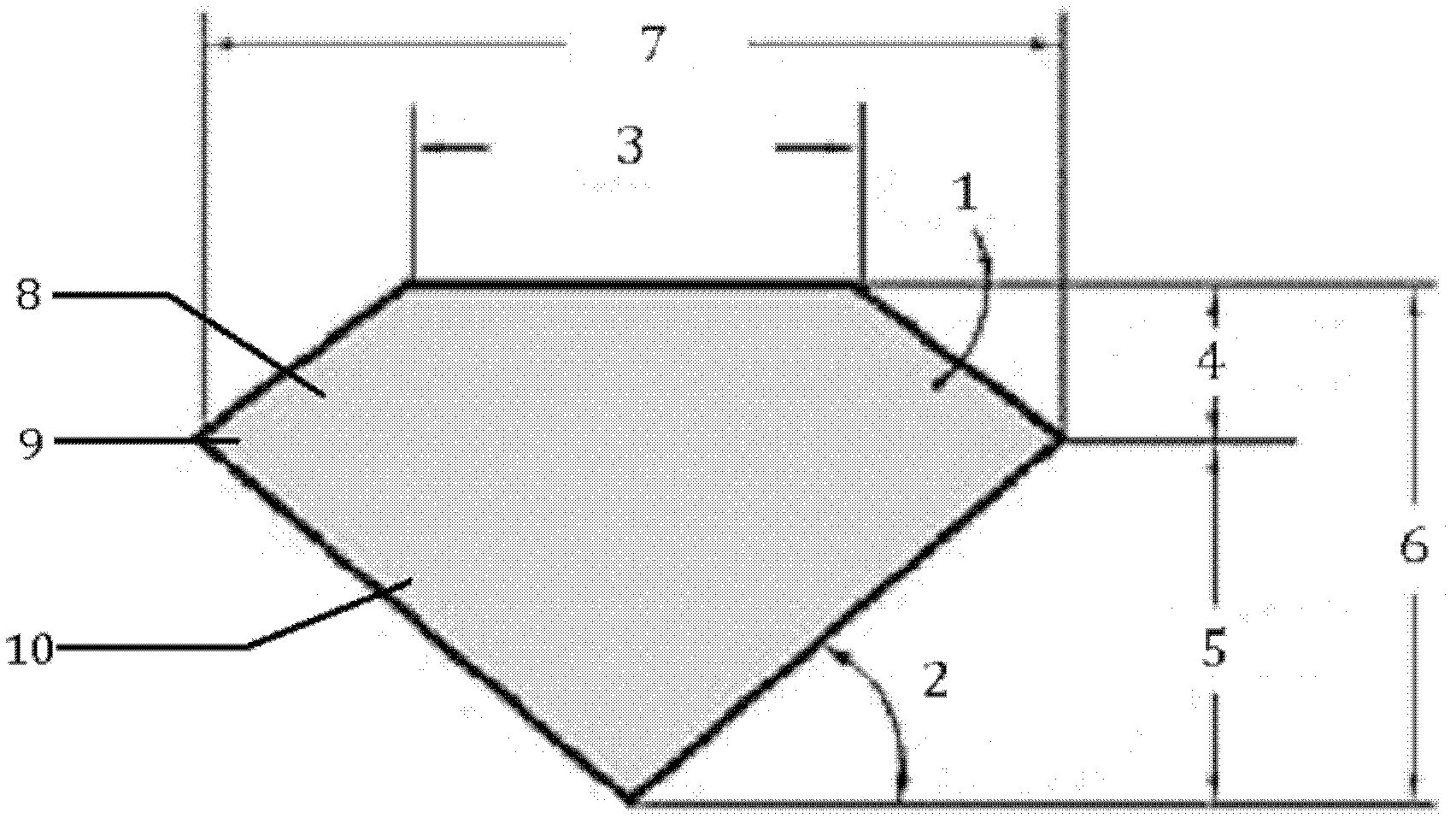

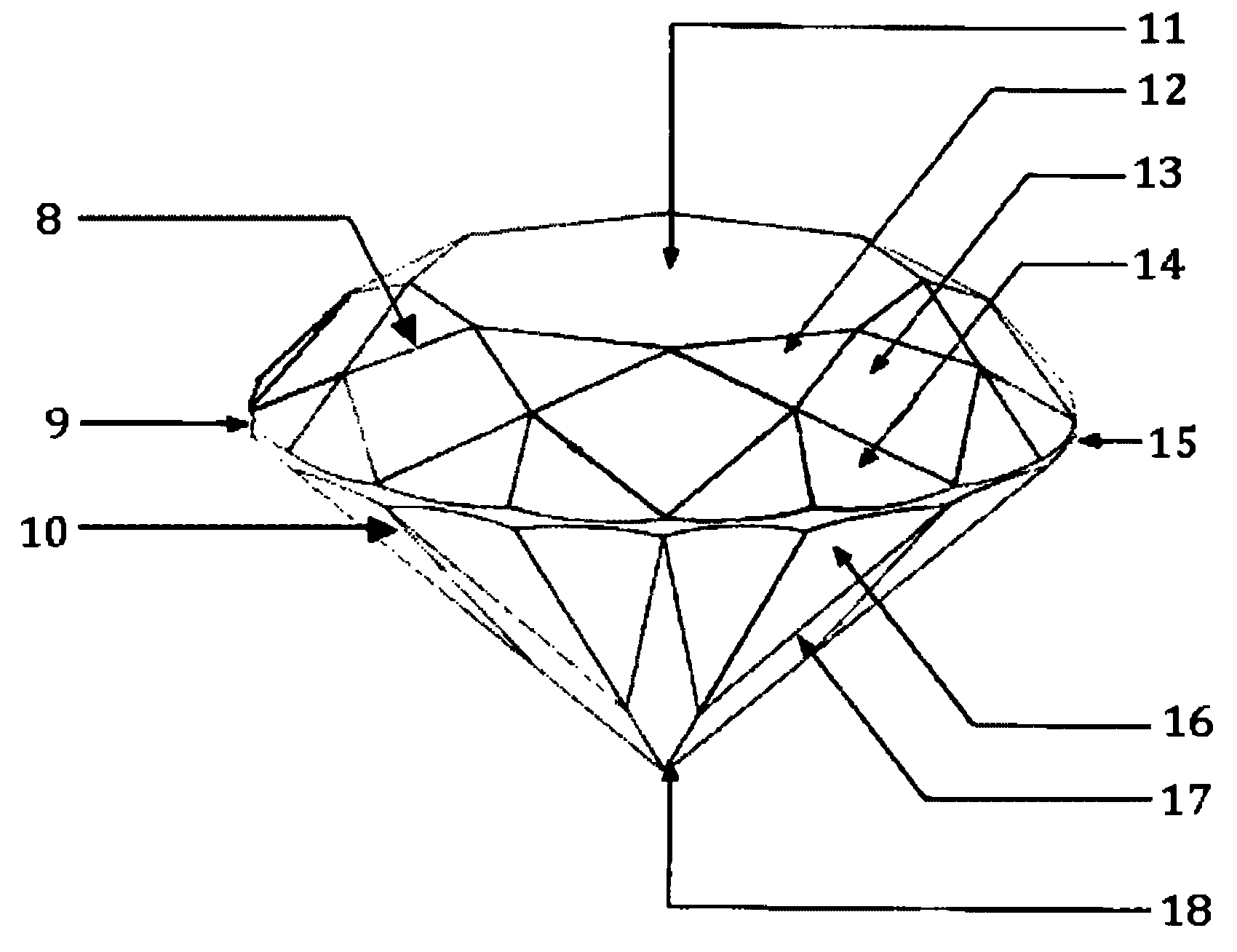

[0045] Embodiment 1, the standard round brilliant cutting shape of moissanite gemstone, such as figure 2 As shown, the surface C of moissanite is used as the table top, the table top 11 is a regular octagon, and the crown has eight crown main faces 13, sixteen upper waist faces 14, and eight star facets 12; the pavilion has eight pavilion main faces Face 17 and sixteen lower waist faces 16 are cut and ground according to the following angles and ratios:

[0046] The crown angle is 34°~35°, the pavilion angle is 41°~42°, the platform width ratio is 49%~51%, the crown height ratio is 17%~18%, the pavilion depth ratio is 43%~44%, the total depth The ratio is 62% to 65%, the star facet angle is 29° to 30°, the upper girdle angle is 35° to 37°, and the lower girdle angle is 42° to 44°. as described in the table below

[0047]

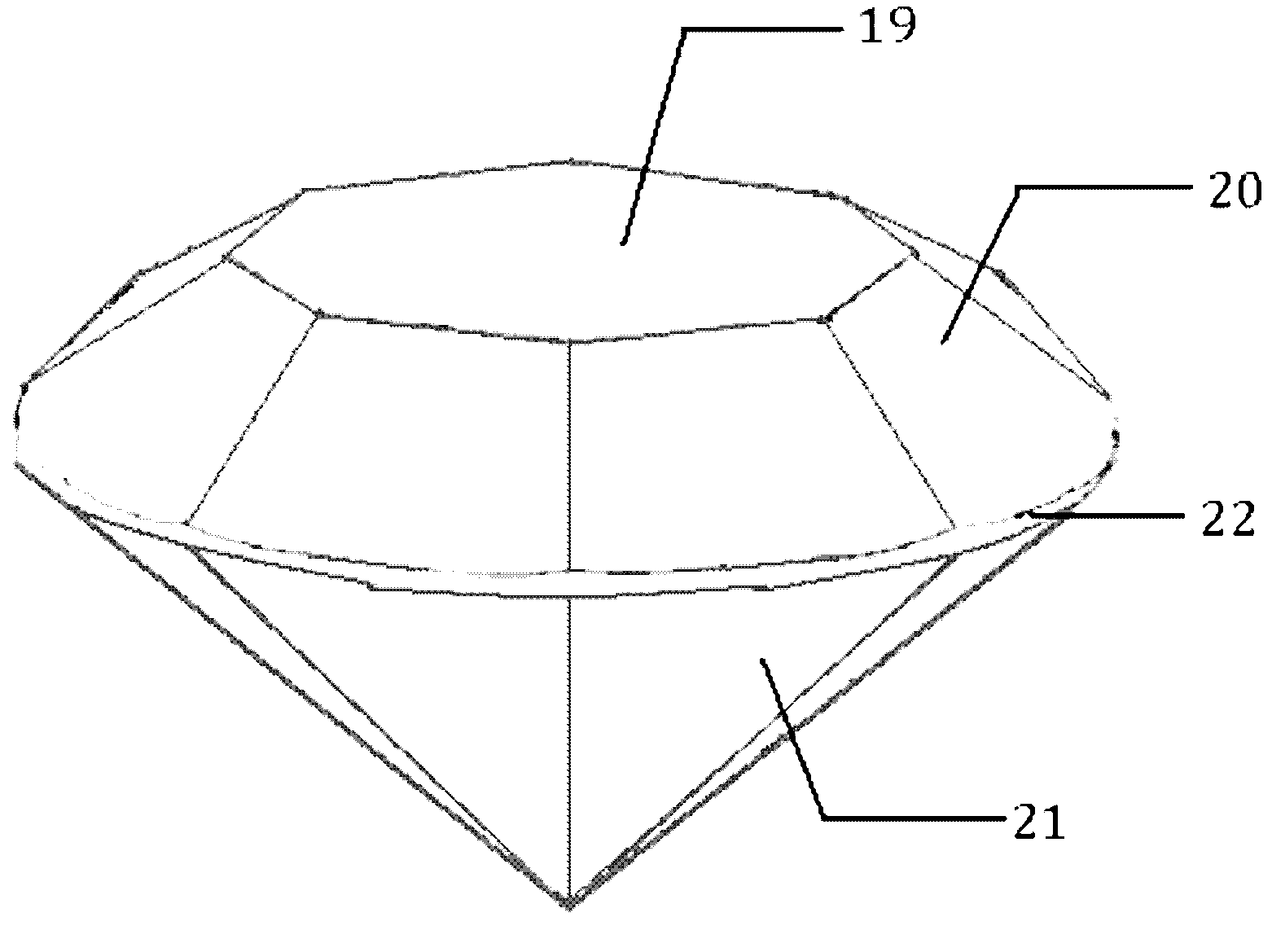

[0048] The standard round brilliant cut shape of embodiment 2, 6H moissanite gemstone, such as figure 2 As shown, the surface C of moissanite is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com