Smoke gas wet method sulfur removal and dust removal integral treatment system

A wet desulfurization and treatment system technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of high cost and slow processing efficiency, and achieve small footprint, easy control, and not easy to scale Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

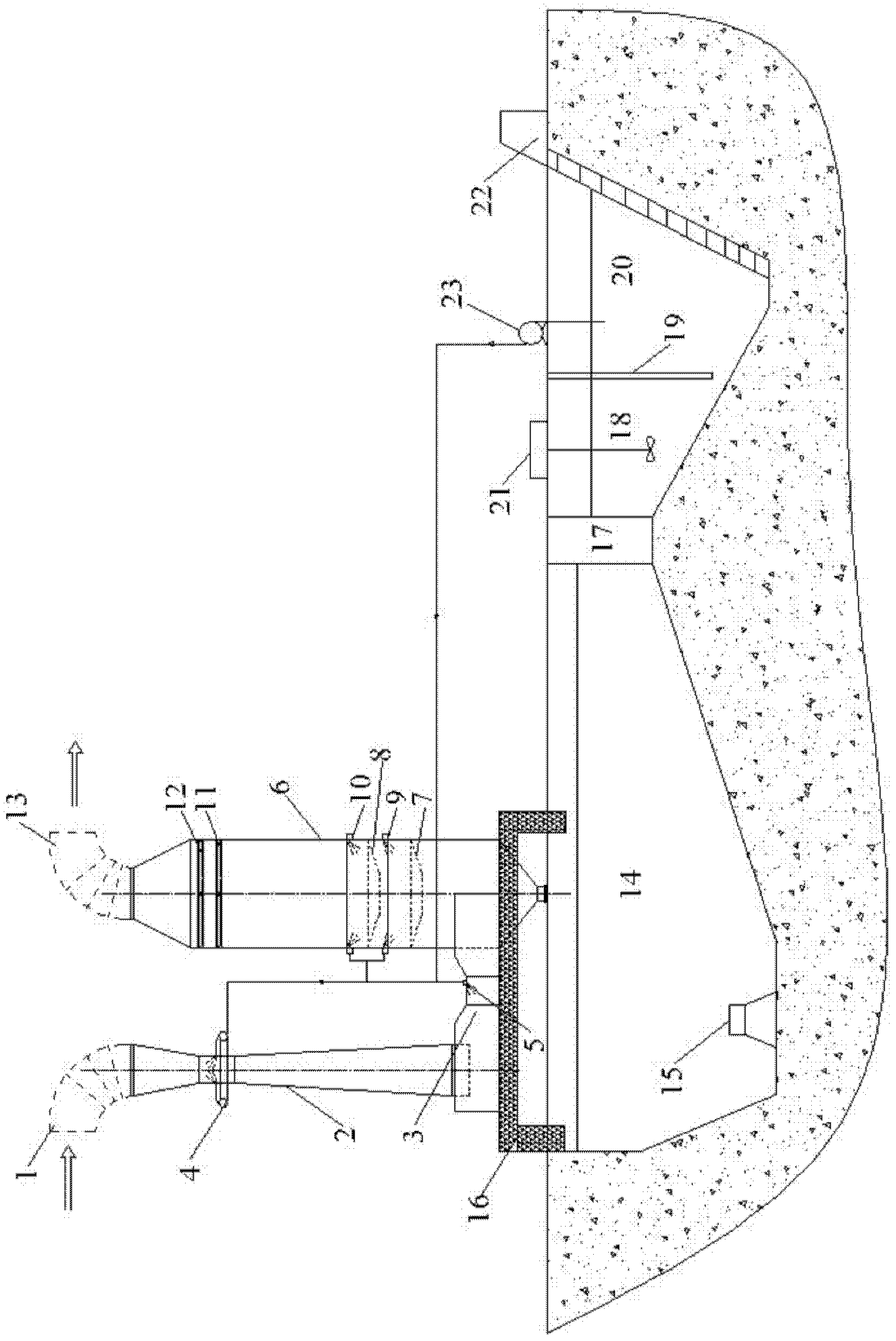

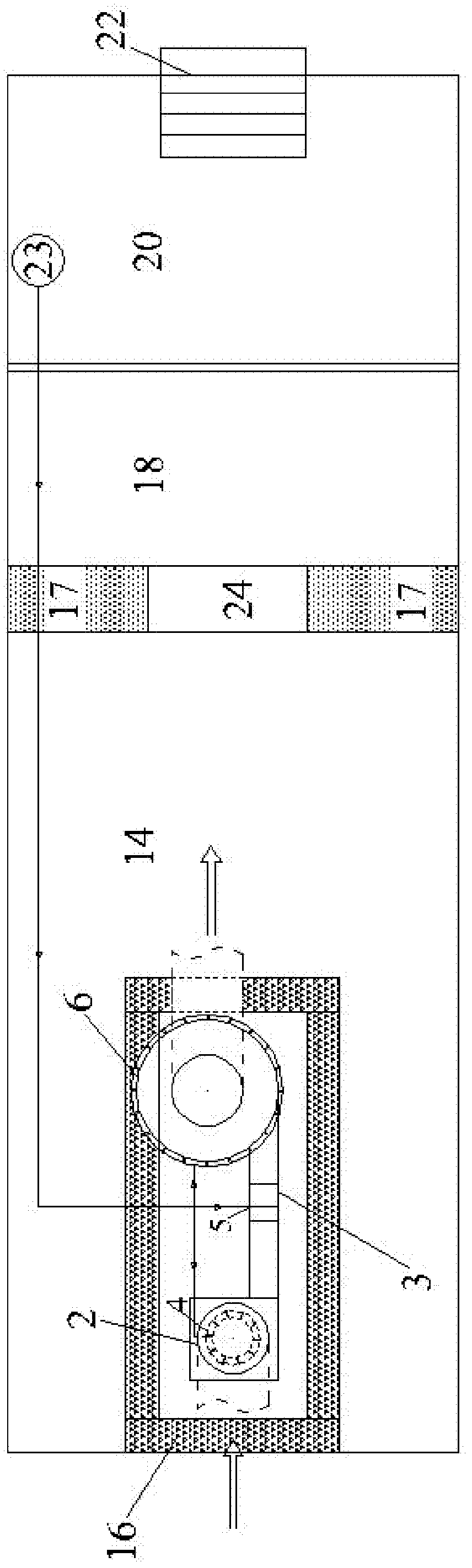

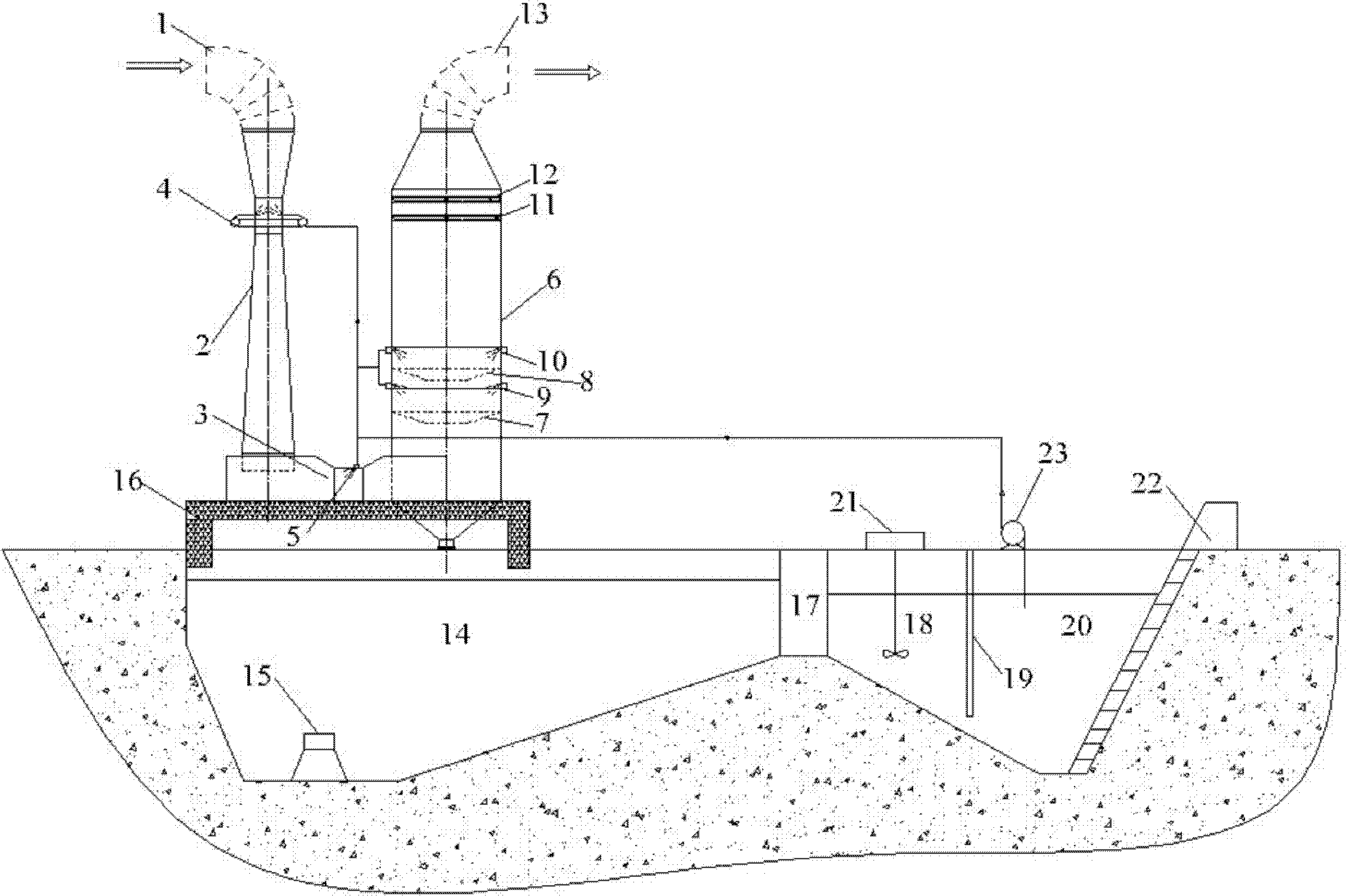

[0028] see figure 1 , figure 2 , the present invention includes a dust removal system for dust removal and preliminary desulfurization of flue gas, a cyclone absorption dehydration system for desulfurization and dehydration of flue gas again, a water treatment system for providing desulfurization treatment liquid, and the dust removal system includes a Venturi tube The cyclone absorption dehydration system includes a cyclone absorption dehydration tower 6, and the water treatment system includes a sedimentation tank 14 for receiving waste liquid, a sand filter 17 for filtering waste liquid, and a regeneration tank for treating waste liquid by adding medicine. The pool and the circulation pump 23 used to transport the desulfurization treatment liquid, the output end of the Venturi tube is connected to the swirl absorption dehydration tower 6, the bottom of the swirl absorption dehydration tower 6 has a waste liquid outlet, and the water surface of the sedimentation tank 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com