Method for producing chain pits of round-link chain

A production method, the technology of the circular chain, applied in the direction of belt/chain/gear, gear teeth, program control, etc., can solve the problems of low processing accuracy and efficiency, inability to apply parts processing, and huge automatic programming program, etc., to improve processing The effect of quality, short program, and reduction of processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to facilitate those skilled in the art to better understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments, and the following description is only exemplary.

[0027] Taking a sprocket body of a medium and double-chain scraper machine as an example, the specific processing process is as follows:

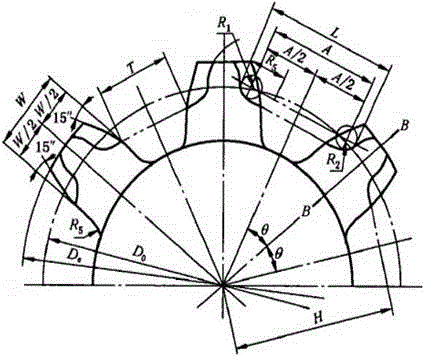

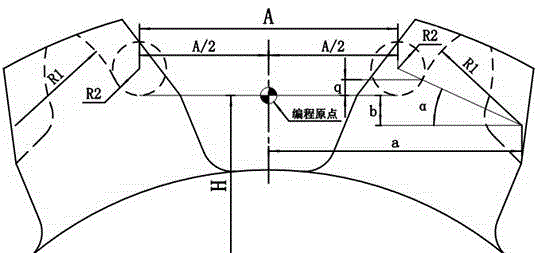

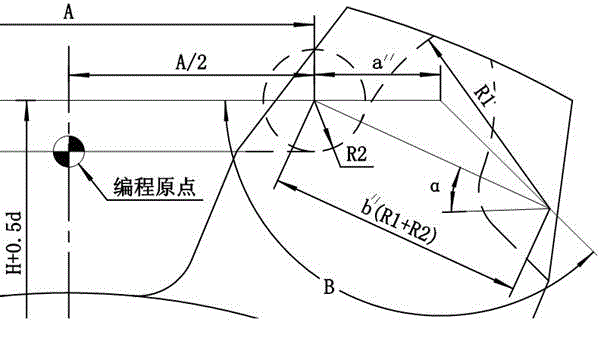

[0028] 1. Fix the workpiece on the center of the basic rotary table, the circular arc of the chain pocket plane faces the machine tool spindle and the bottom plane of the chain pocket is perpendicular to the machine tool spindle. Refer to the attached figure 2 , take the center position of the bottom of the chain nest as the origin of the programming coordinate system, refer to the attached figure 2 and attached Figure 7 Set the origin offset and correct the fixed workpiece;

[0029] 2. Rough processing:

[0030] 1) Select the tool for rough machining, and set the processing paramete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com