Process method and device for desalting seawater at low temperature

A process method and process device technology, applied in the field of low-temperature multi-effect seawater desalination process methods and devices, can solve the problems of increasing equipment investment and large volume, and achieve the effects of improving thermal efficiency, increasing operating temperature, and reducing fouling growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

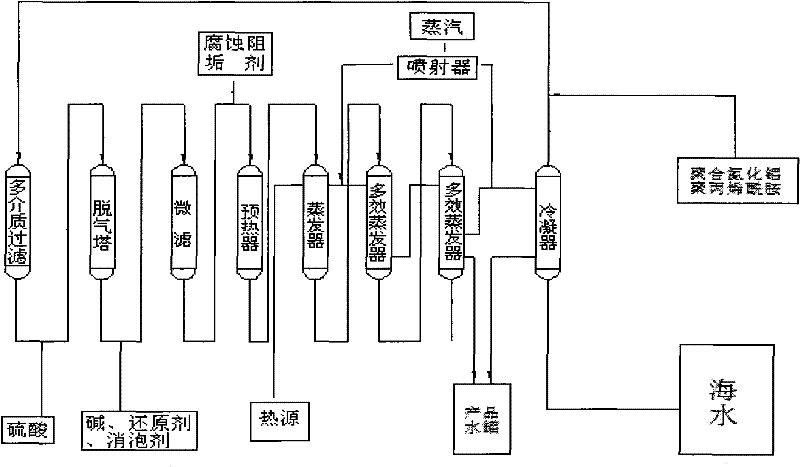

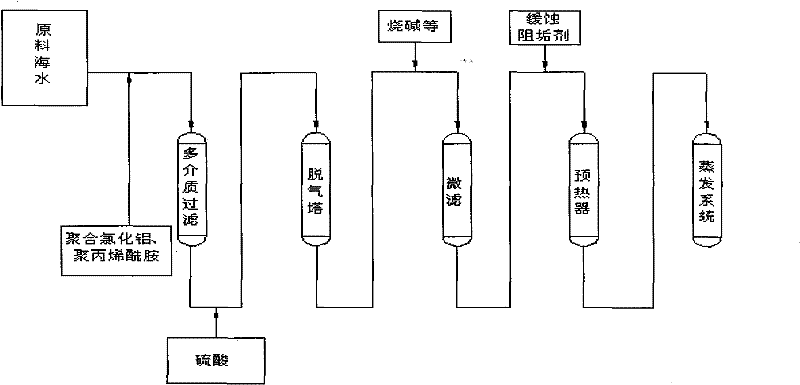

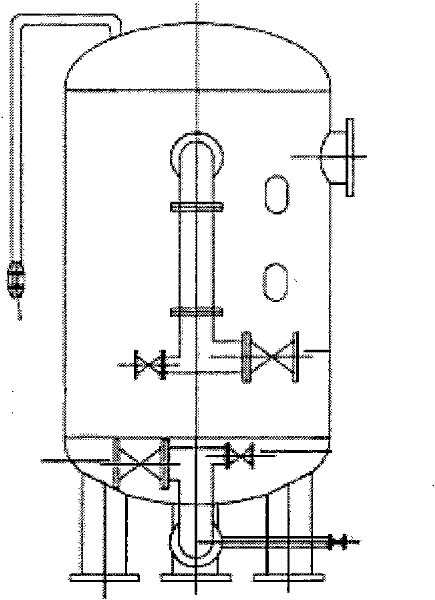

[0037] The low-temperature multi-effect seawater desalination process device of the present invention includes a multi-media filter, a degassing tower, a microfilter, a preheater, an evaporator, a first multi-effect evaporation tower, a second multi-effect evaporation tower, The condenser is formed; the steam outlet of the second multi-effect evaporation tower is connected to the interface of the steam ejector through a connecting pipe, and the outlet of the steam ejector is connected to the steam inlet of the first multi-effect evaporation tower.

[0038]The seawater bus is connected to the condenser, and the condenser is respectively connected to the multimedia filter and the second multi-effect evaporation tower. The condenser is connected to the outlet of the degassing tower, and the outlet of the condenser is connected to the port of the steam ejector through a connecting pipe. The multimedia filter is connected with the degassing tower preheater.

[0039] The raw seawat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com